160 ASC110 / ASC130 / ASC150

3.6. Individual Operations of Maintenance

((

((

(

Every 1000 Hours or Once a Year Every 1000 Hours or Once a Year

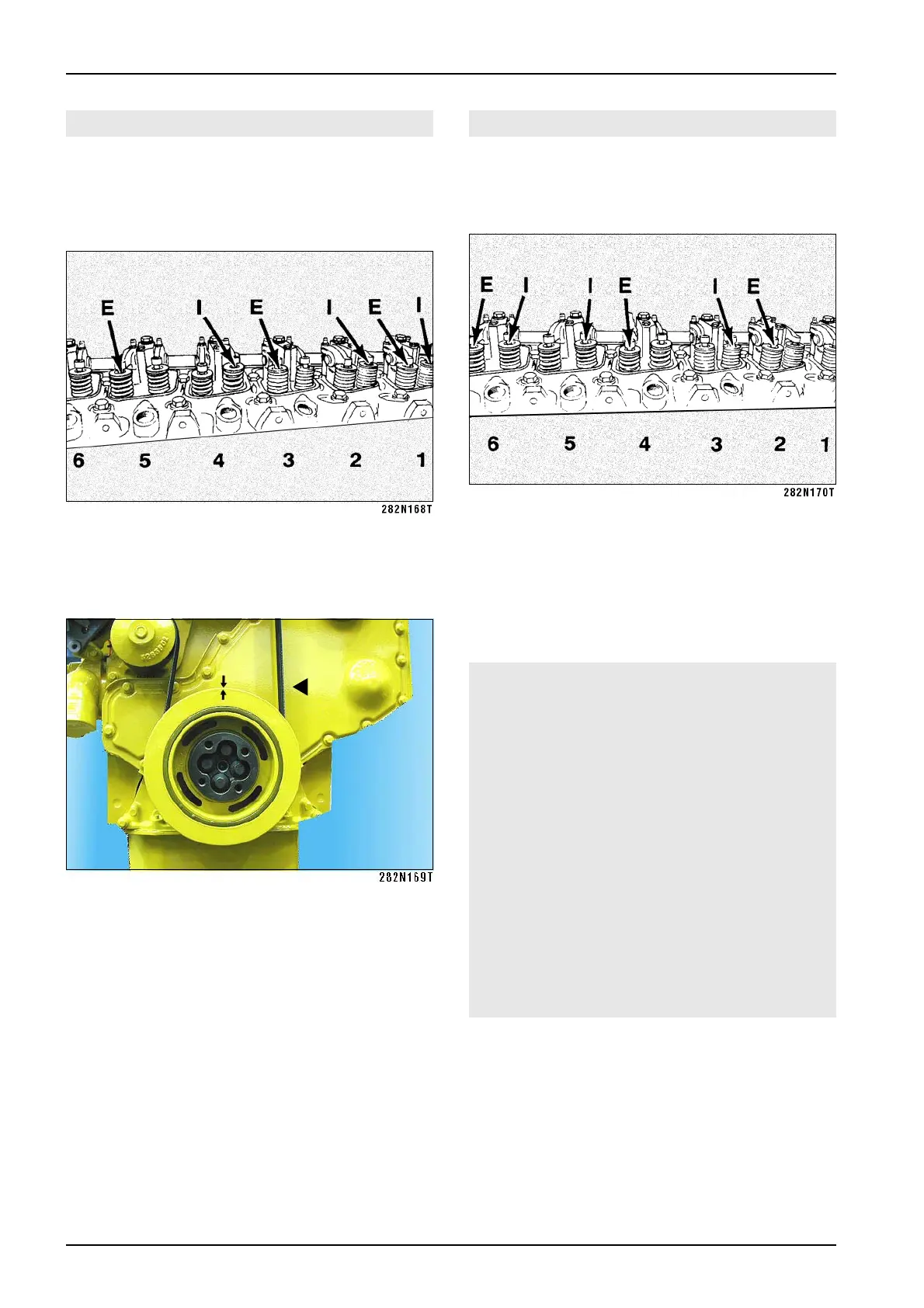

• Check and adjust clearances of remaining valves

according to the figure. After tightening the locking nut

check again the clearance.

• Make a mark on the torsion vibration damper and turn

the crank shaft by 360°.

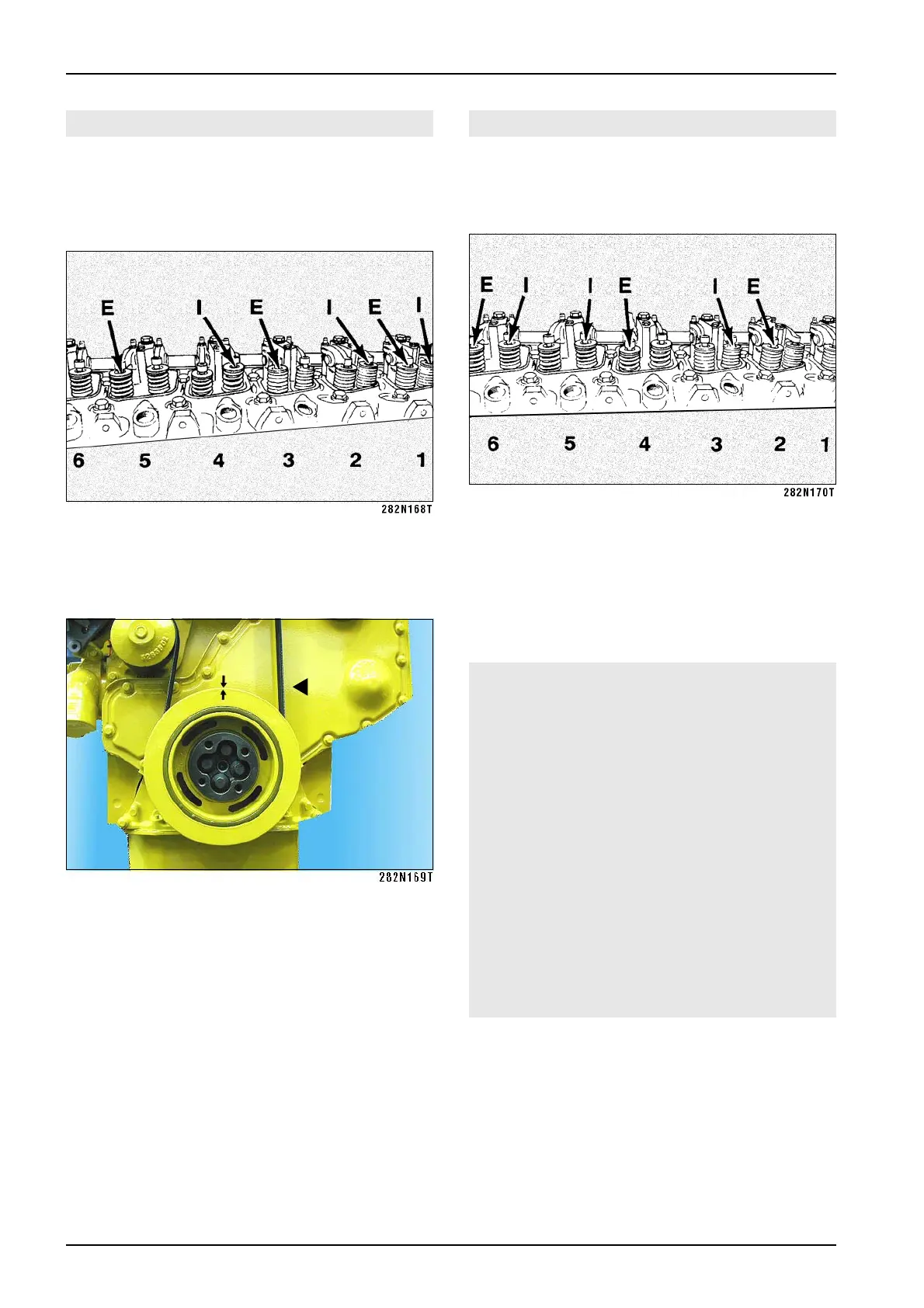

• Check and adjust clearances of the remaining valves

according to the figure.

• Mount again the valve covers. Mount the inlet air

piping.

! WARNING!

Check and adjust the valves when the engine is

cooled down to below 60 °C.

The order of cylinders is 1 - 4 from the ventilator

belt pulley; valve clearances:

- Inlet valves: 0.254 mm (0.010 in).

- Exhaust valves: 0.508 mm (0.020 in).

The clearance is adjusted correctly, when one can

feel resistance when moving the feeler gauge.

(I) sign applies for the inlet valves, (E) for the

exhaust valves.

After adjustment tighten the locking nuts and the

cover bolts with torque of 24 Nm (18 ftlb).

Loading...

Loading...