117ASC110/ASC130/ASC150/ASC200/ASC250

OPERATING INSTRUCTIONS

1

2

2.9.4. Filling tyres with water

This is useful to increase weight allocated to axle and to lower gravity center when working in extreme conditions. Fill

the inside of tyres with a solution of water, hydrated lime (calcium hydroxide) and anhydrous calcium chloride (CaCl

2

)

or magnesium chloride (MgCl

2

). See the table for mixing ratios for individual temperatures, for one tyre:

Preparing the solution:

! NOTE !

Wash any spills with fresh water.

Protect metal parts and electric system from

contact with the solution.

The solution must not be filled in the engine cooling

system.

Always add anhydrous calcium

chloride CaCl

2

to water, never vice

versa!!

Filling procedure:

• Secure the drum by scotch blocks from both sides, lift

the rear part of the roller and release brake of wheel

hydromotors, see chapter 2.9.1.

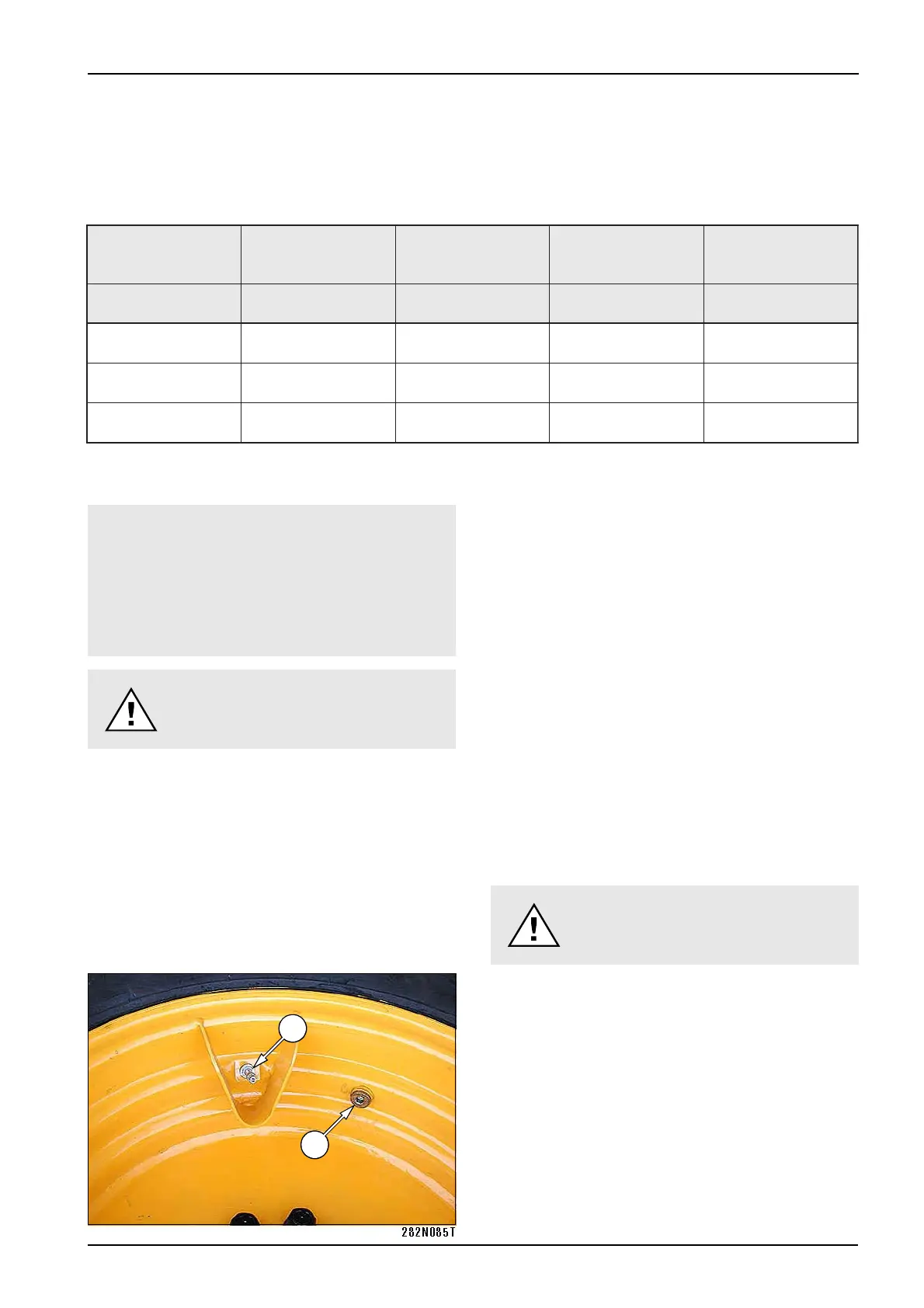

• Rotate tyres so that valves (1) are at top positions. Blow

off both tyres and screw out inflation valves (1) and

caps (2).

• Screw the filler (gr. 635 - spare parts list) to the cap

opening (2) and insert the hose of filling device (higher-

positioned container, pump etc.). Start filling tyres with

prepared solution.

• Repeat the procedure for the other tyre.

• Unscrew the filler and screw in inflation valves and

caps again.

• Inflate tyres to the prescribed pressure and screw in

valve caps.

• Activate brakes - see chapter 2.9.1.

• In regions where temperatures do not fall below zero

(i.e. down to 0°C (32°F)), add extra weight in the form

of solution of water and copper sulphate CuSO

4

5H

2

O

(bluestone).

• For one tyre, mix 500 l (132 US gal) of water and 0.17

kg (0.4 lb) of copper sulphate CuSO

4

5H

2

O.

• Fill tyres with the solution.

Use safety goggles (safety shield)

and rubber gloves.

tniopgnizeerF retaW

edirolhcmuiclaC

lCaC

2

edixordyhmuiclaC thgiewdeddA

]F°[C° ]SUlag[l ]bl[gk ]bl[gk ]bl[gk

]0[81-]121[854562[021] ]4.4[2)0821(085

]31-[52-]121[854]213[141]9.4[2,2)3231(006

]22-[03-]121[854]343[5,551]5.5[5,2)0631(716

Loading...

Loading...