104 ASC70

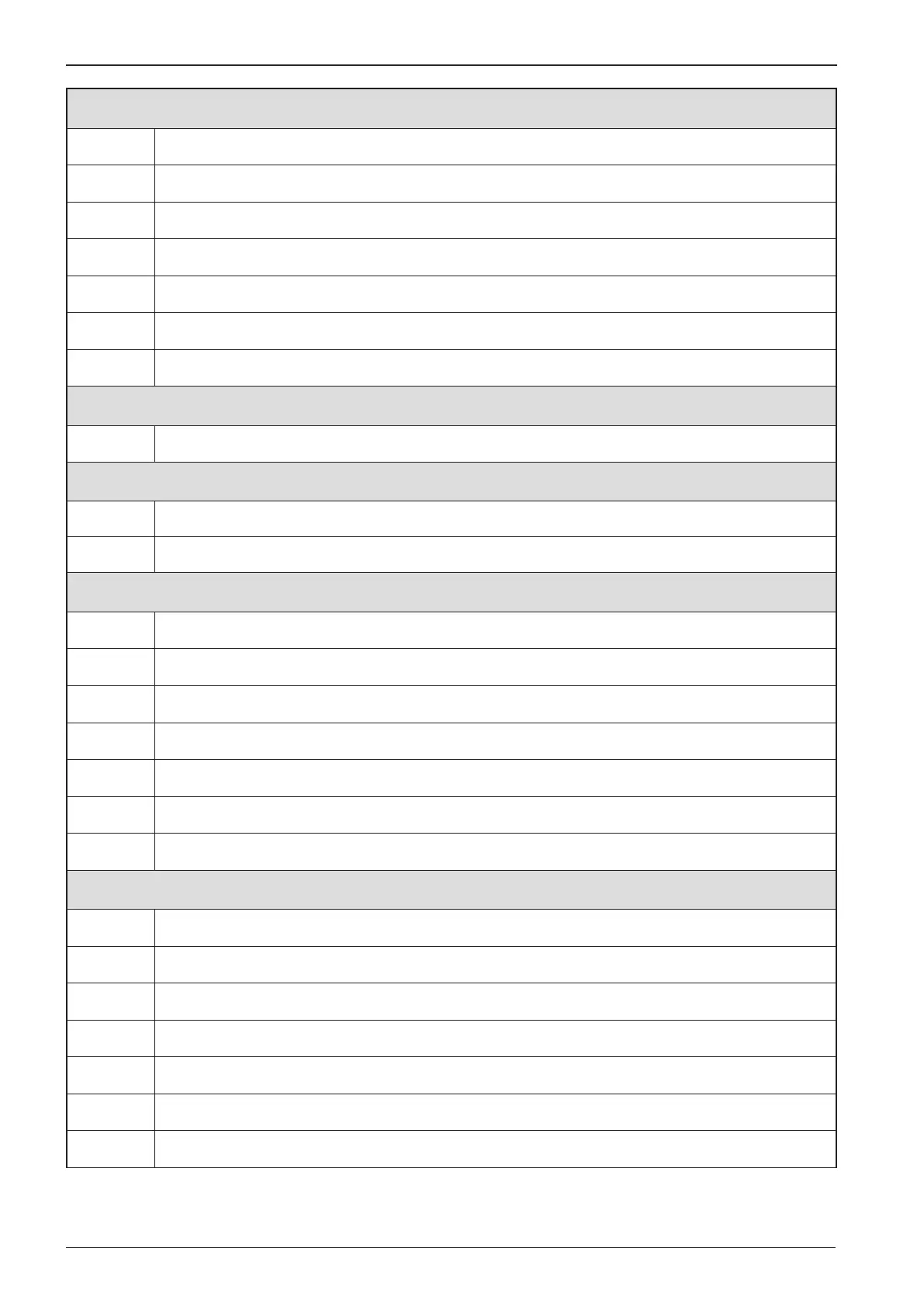

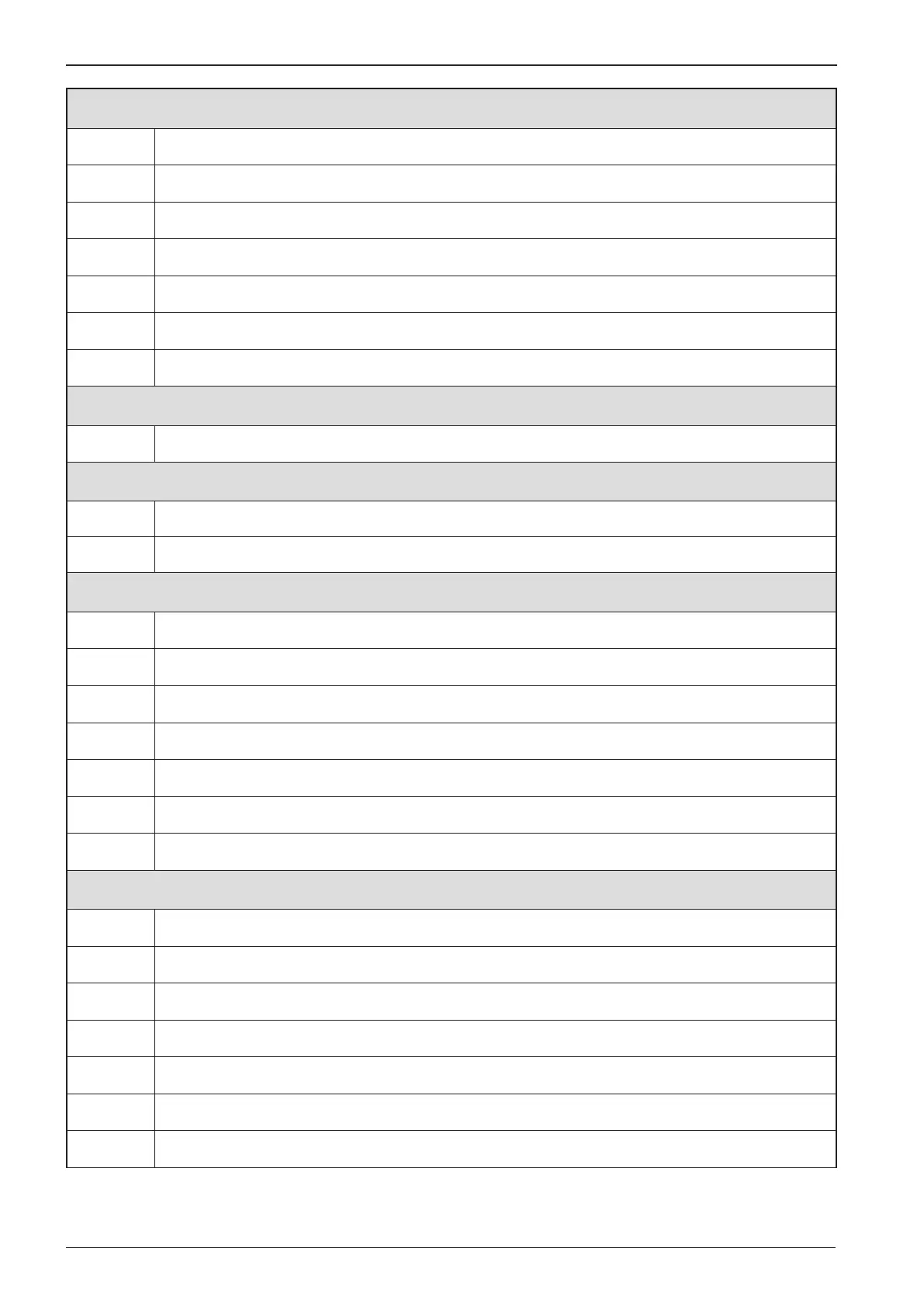

3.4. Lubrication and Maintenance Chart

Every 20 hours of operation (daily)

3.6.1. Engine oil level check

3.6.2. Engine cooling liquid level check

3.6.3. Hydraulic oil level check

3.6.4. Crankcase breather tube

3.6.5. Fan and engine belt condition check

3.6.6. Air lter dust valve check

3.6.7. Warning and control devices check

Every 100 hours of operation (weekly)

3.6.8. Tyre pressure check

After 100 hours of operation

3.6.22. Wheel bolts tightening check *

3.6.24. Oil in the travel gearboxes change *

Every 250 hours of operation (3 months)

3.6.9. Engine oil change

3.6.10. Engine inlet piping check

3.6.11. Battery check

3.6.12. Machine lubrication

3.6.13. Oil in the vibrator check

3.6.14. Oil in the travel gearboxes check

3.6.15. Pad foot segments inspection

Every 500 hours of operation (6 months)

3.6.16. Fuel lter replacement

3.6.17. Air lter elements replacement

3.6.18. Filters of the cab ventilation and heating replacement

3.6.19. Engine cooling liquid check

3.6.20. Wiring check

3.6.21. Air lter of the air conditioning system replacement

3.6.22. Wheel bolts tightening check

Loading...

Loading...