80 ASC70

396346

2.7. Machine control and use

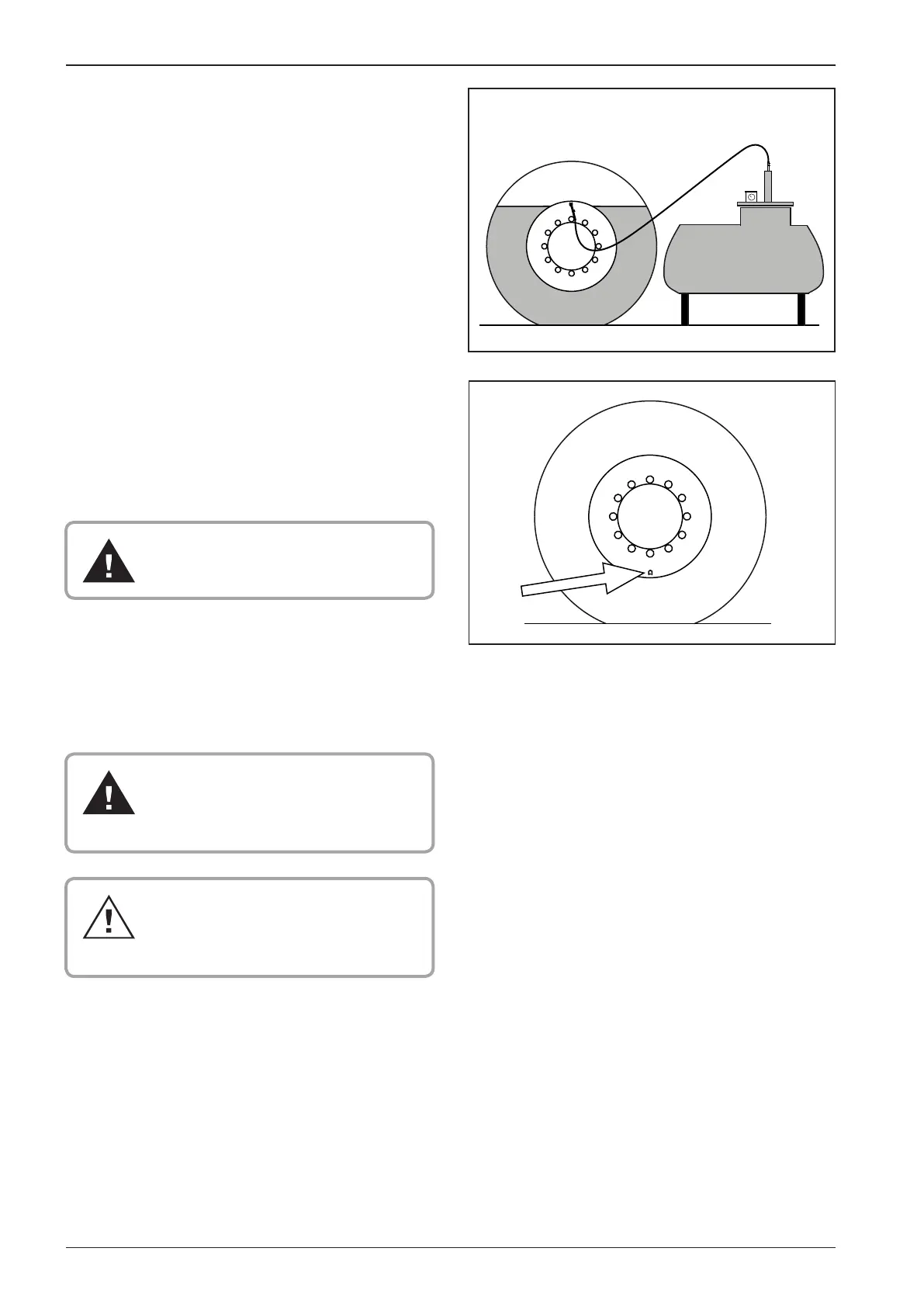

• Mount the hose from the lling equipment (a tank located

above, pump, etc.) on the ller neck and ll the tyres with

the solution.

• During the lling, air escapes from the tyre through the side

opening from the ller neck. The tyre is suciently lled (at

75%) when the solution starts owing out through the ope-

ning.

• Unscrew the ller neck, screw the valve insert back on, and

inate the tyre to a pressure of 150kPa (21,8PSI).

Draining procedure:

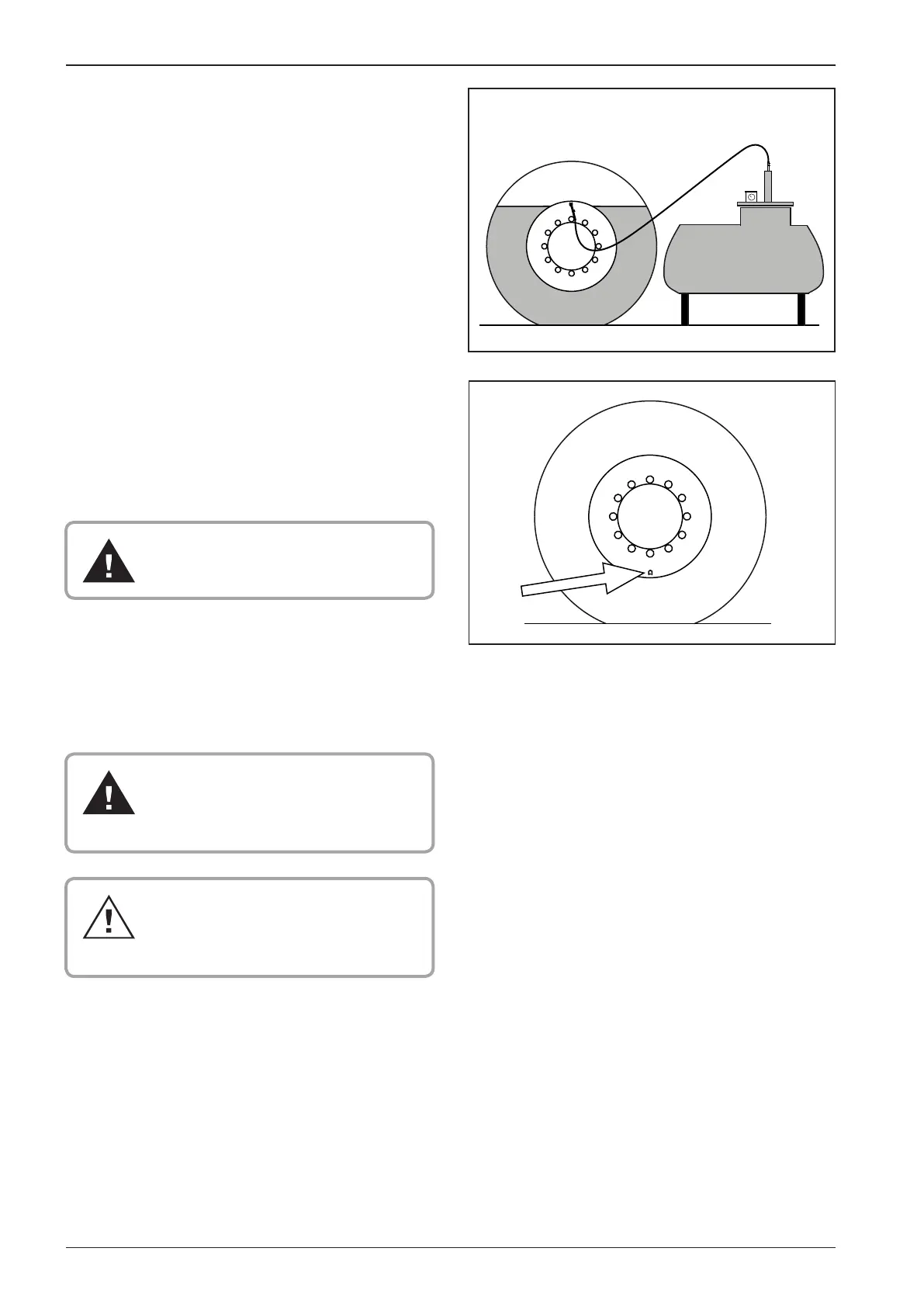

• Move the machine to a rm base. The lling valves should be

in the extreme lower position. Secure the drum with blocks

on both sides.

• Unscrew the removable valve insert and let the solution

ow out.

The solution can spurt out after unscrew-

ing the valve insert.

• As soon as the solution does not ow out due to a decrease

in pressure, screw on the ller neck and inate the tyre to a

pressure of 150kPa (21,8PSI).

• After the tyre has been inated, remove the ller neck and

screw the valve insert back on.

Protect your eyes with glasses (face shield)

and your hands with rubber gloves!

Add calcium chloride CaCl

2

to water, never

vice versa!

Wash away spilled solution with clean

water.

Solution may never come into contact

with metal parts and wiring.

Loading...

Loading...