Asycube - Asyril SA

Programming Guide

15/83

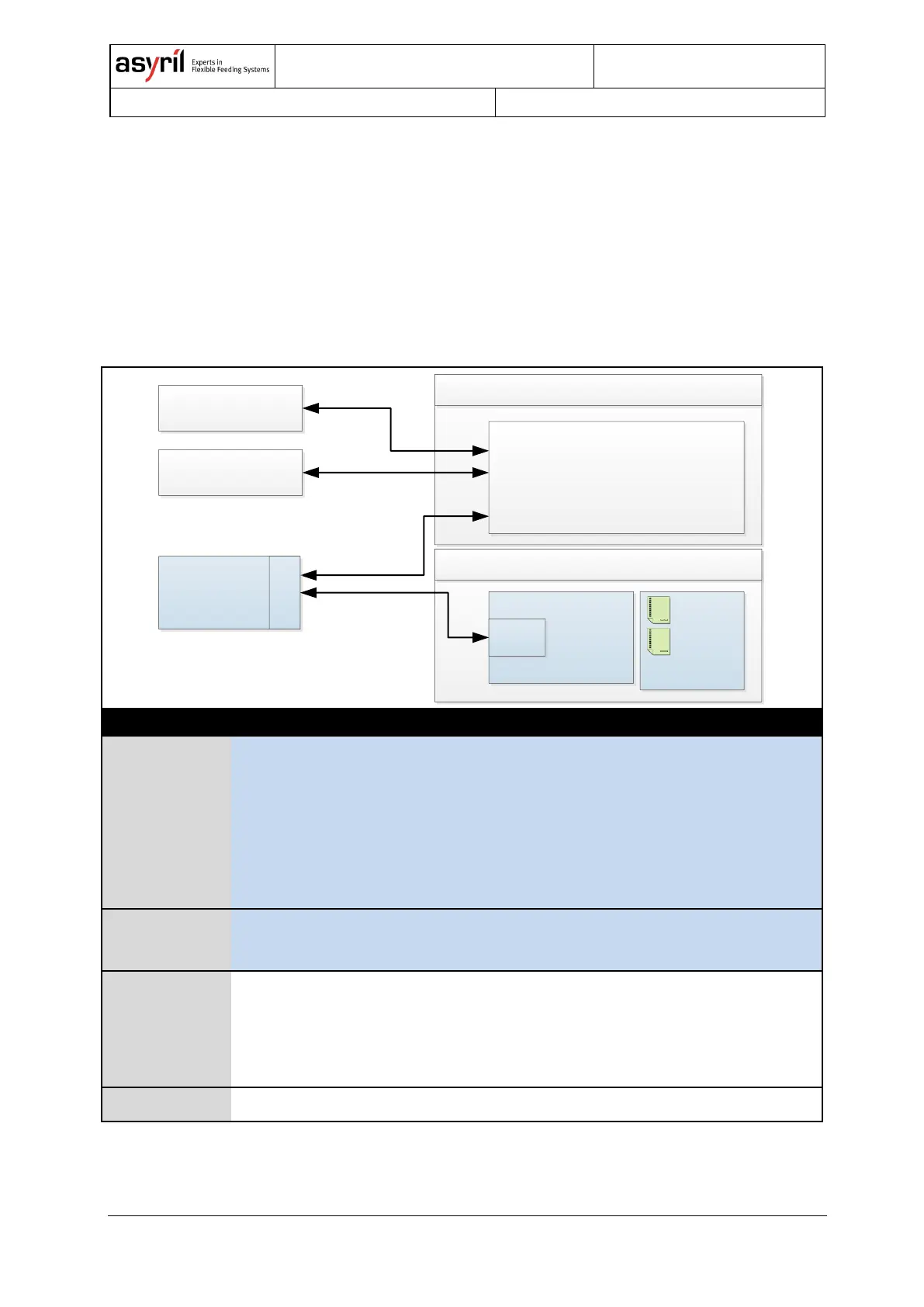

3.1.5. Modbus TCP connection with the Asycube, configuration with

Asycube HMI

In this integration mode, the integrator uses the Asycube HMI to configure the Asycube from

an external PC (e.g. Laptop). The integrator communicates with the Asycube from his own

system (e.g. PLC) through Modbus TCP in order to execute the vibrations. Please refer to

Chapter 6 for more information on Modbus TCP. As an option, a gateway can be used to

convert the Asycube Modbus TCP data to industrial fieldbus data for the controller.

HMI PC (can be the same as controller)

PC

Controller

Asycube HMI

.fconf

.fseq

CAMERA

ROBOT

.dll

ASYCUBE

Firmware

MODBUS TCP

Generation and synchronization of the desired vibration

Execute sequences

Save and reload 25 vibration sets (26 for the reload)

Save and reload 25 sequences (26 for the reload)

Activation of the outputs and backlight

Choice/Management of the optimal sequence based on the vision feedback

Configuration and optimization of the feeding (vibration) parameters

Configuration and optimization of the sequences

Communication with the Asycube

Recipe management (memorize vibration set ID and sequence ID for each

component).

Synchronization of the feeder and the machine

Treatment of the recipe (read/write parameters)

Table 3-5: Integration mode: Asycube only

Loading...

Loading...