Manual, F/T Sensor, Data Acquisition (DAQ) Systems

Document #9620-05-DAQ.indd-20

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

20

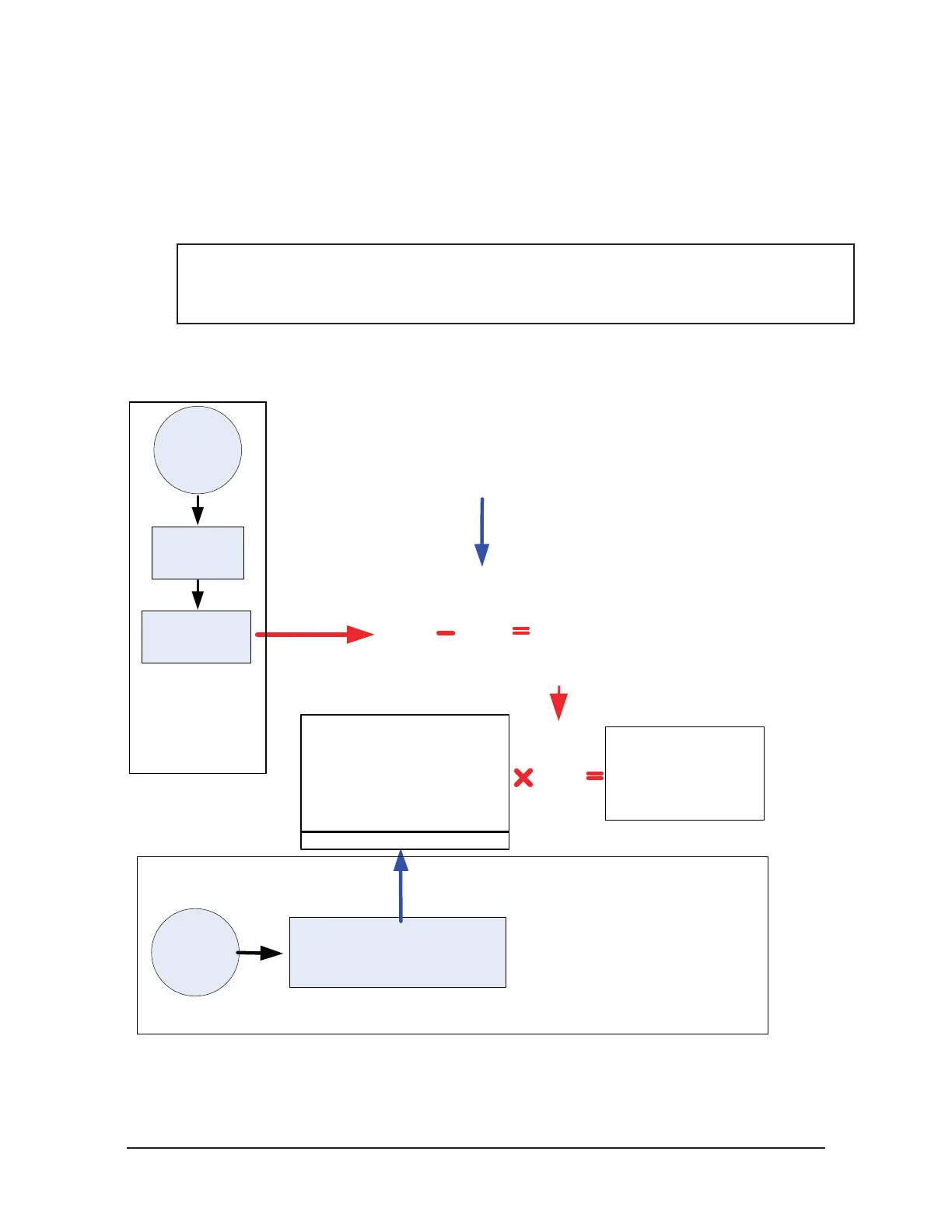

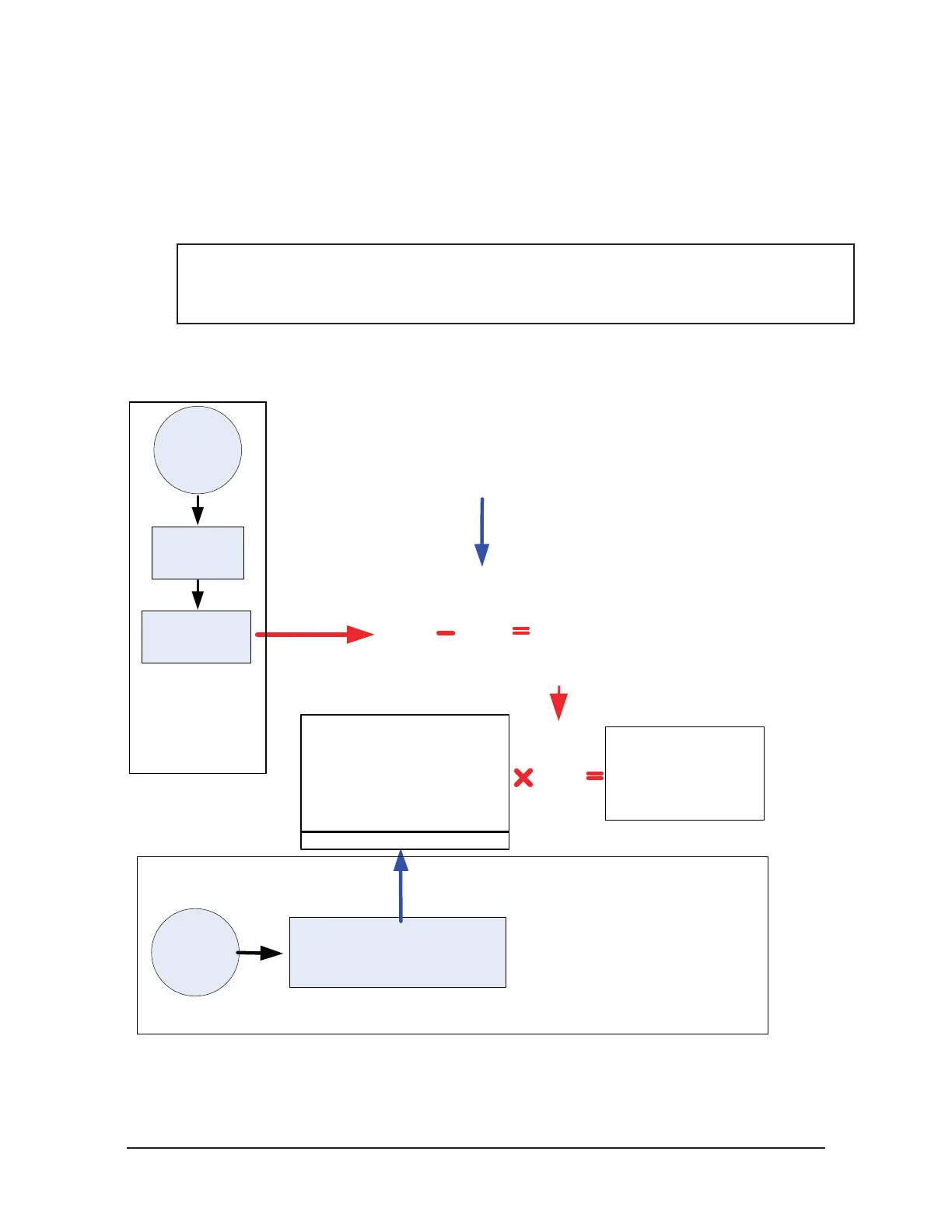

3.3 Load Calculation

Calculations must be performed to derive the loads sensed at the transducer. The transducer reports the

loads as composite values that require conversion to values corresponding to the six Cartesian axes. ATI

supplies software to perform these calculations. Both the software and the transducer’s calibration values

can be accessed from the media that accompanies the transducer. Figure 3.4 shows the calculation required

to convert strain gage data into force and torque data. This method can be used in Matlab, or through other

software that enables manual matrix calculations.

NOTICE: The CD included with the DAQ system contains extensive help les on its software

that will benet both the beginner and advanced user. The CD even includes a spreadsheet to

help advanced users with calculations, see the Advanced Techniques section of the help le for

more information.

Figure 3.4—FT Matrix Calculations

STG0

STG1

STG2

STG3

STG4

STG5

bias0

bias1

bias2

bias3

bias4

bias5

bSTG0

bSTG1

bSTG2

bSTG3

bSTG4

bSTG5

FyG0

FzG0

TxG0

TyG0

TzG0

FyG1

FzG1

TxG1

TzG1

TzG1

FyG2

FzG2

TxG2

TyG2

TzG2

FyG3

FzG3

TxG3

TyG3

TzG3

FyG4

FzG4

TxG4

TyG4

TzG4

FyG5

FzG5

TxG5

TyG5

TzG5

Runtime Matrix

Bias Vector for

Offset Correction

Operations marked RED are to be performed

for each measurement sample.

Operations marked BLUE are to be performed

only once at the beginning of a measurement.

Transducer

ATI Amplifier

(if included)

Customer’s

Data Acquisition

System

6 gage output

voltages data

Transducer

Calibration

File

Open Excel sheet on the website at

http://www.ati-ia.com/Products/ft/

software/daq_software.aspx, called

“DAQ F/T Manual Calculations”

Working

calibration matrix

Determine Offset

Correction Voltage

bias0

bias1

bias2

bias3

bias4

bias5

Note:Temperature compensation

is usually not required. Only older

models may need software

temperature compensation.

Calibration Matrix

Strain

Gage

Data

Force and

Torque Data

(Fx Fy Fz Tx Ty Tz)

bSTG0

bSTG1

bSTG2

bSTG3

bSTG4

bSTG5

Load in the FTxxxxx.cal file and copy the working matrix

from the spreadsheet to the blue square area.

3.3.1 Strain Gage Data

Strain gage data represents amplied voltages from the transducers that are converted to digital

data by the Data Acquisition system. Use the demo program to monitor the strain gage data during

installation, this can be use to avoid saturation errors which can damage the transducer.

Loading...

Loading...