Manual, F/T Sensor, Data Acquisition (DAQ) Systems

Document #9620-05-DAQ.indd-20

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

63

7.1 Errors with Force and Torque Readings

Bad data from the transducer’s strain gages can cause errors in force/torque readings. These errors can result

in problems with threshold monitoring, sensor biasing and accuracy. Listed below are basic conditions of

bad data. Use this to troubleshoot your problem. In most cases, problems are easier to detect while viewing

raw strain gage data.

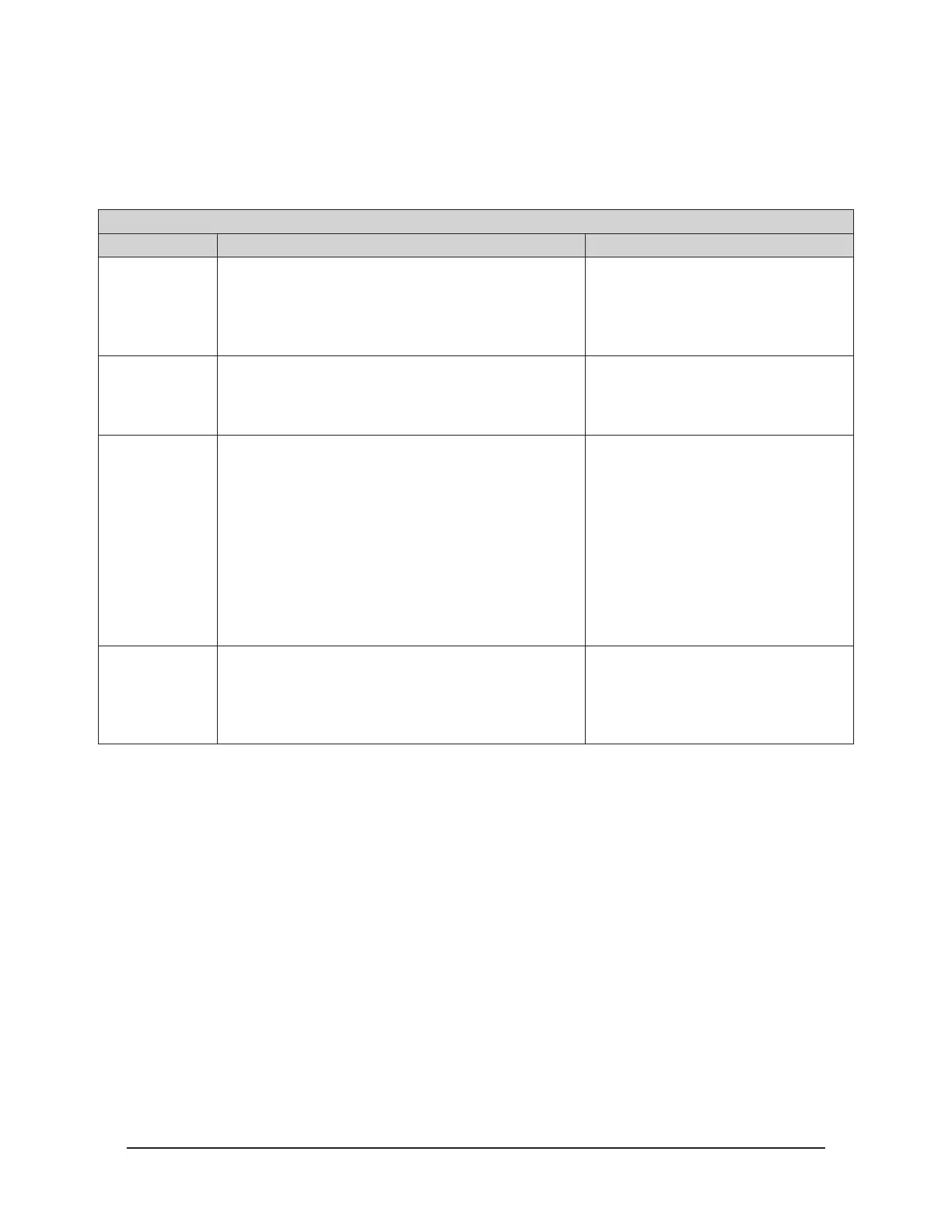

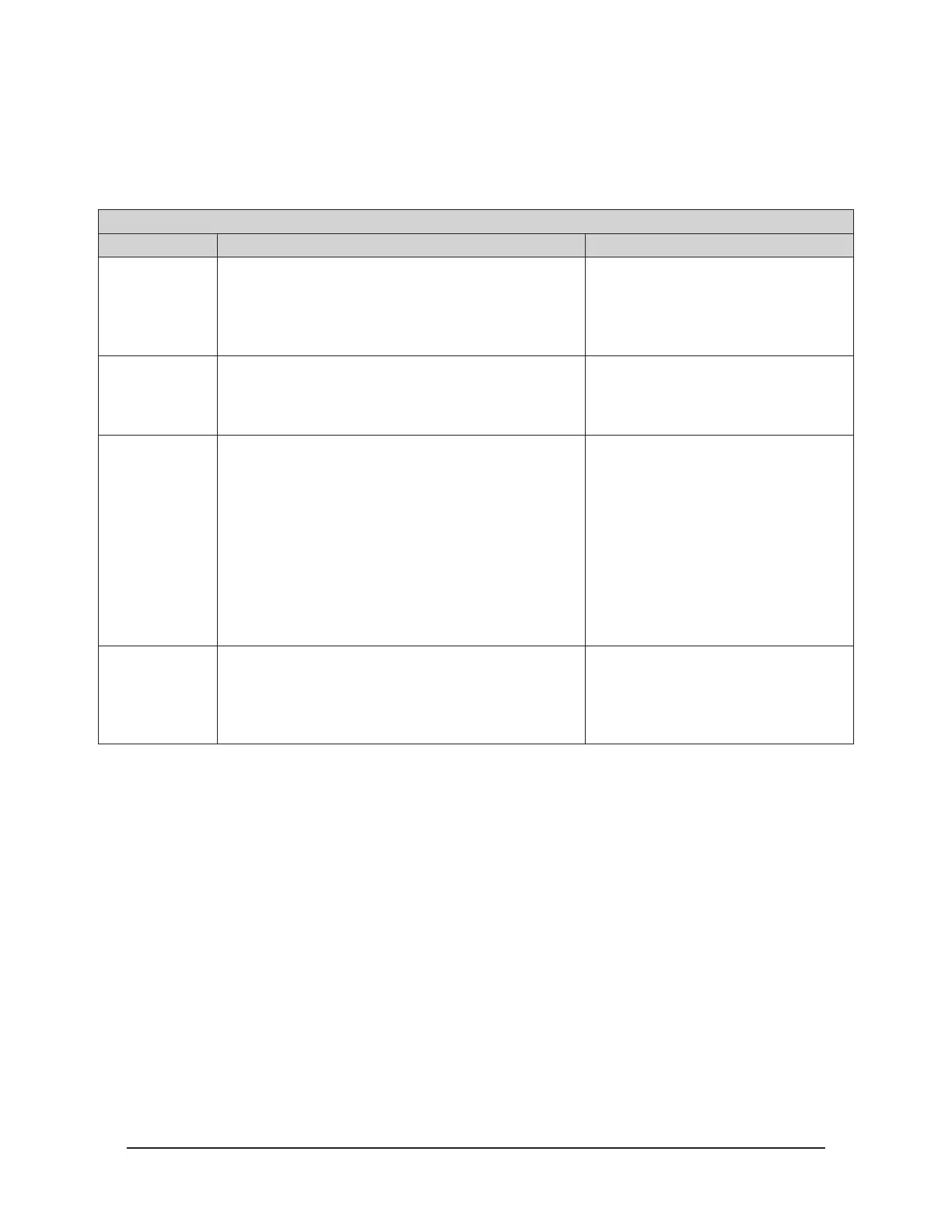

Table 7.1—Troubleshooting Table

Symptom Cause Resolution

Saturation

When the data from a raw decimal strain gage

reads the positive or negative maximums, that

gage is saturated. Saturation occurs if the sensor is

loaded beyond its rated maximum or in the event of

an electrical failure within the system.

Stop applying force to the transducer

and wait until the error clears to

continue. If error does not clear, it

may indicate the overload value has

been exceeded or a loss of power.

Noise

Excessive noise can be caused by mechanical

vibrations and electrical disturbances, possibly

from a poor ground. It can also indicate component

failure within the system.

Make sure the unit is grounded

properly and the area is isolated

from electrical disturbances.

Drift

After a load is removed or applied, the raw gage

reading does not stabilize but continues to increase

or decrease. This may be observed more easily

while viewing resolved F/T data. Drift is caused

by temperature change, mechanical coupling, or

internal failure. Mechanical coupling is caused

when a physical connection is made between the

tool plate and the sensor body (i.e., plastic lings

between the tool adapter plate and the transducer

body). Some mechanical coupling is common, such

as hoses and wires attached to a tool.

Make sure the tool, tool adapter

plate and the transducer body are

isolated from each other and no

debris lies between the transducer

body and tool plate.

Hysteresis

When the sensor is loaded and then unloaded,

gage readings do not return quickly and completely

to their original readings. Hysteresis is caused by

mechanical coupling (explained in drift section) or

internal failure.

Make sure the tool, tool adapter

plate and the transducer body are

isolated from each other and no

debris lies between the transducer

body and tool plate.

Loading...

Loading...