www.baldormotion.com

Basic Installation 3-17MN1919

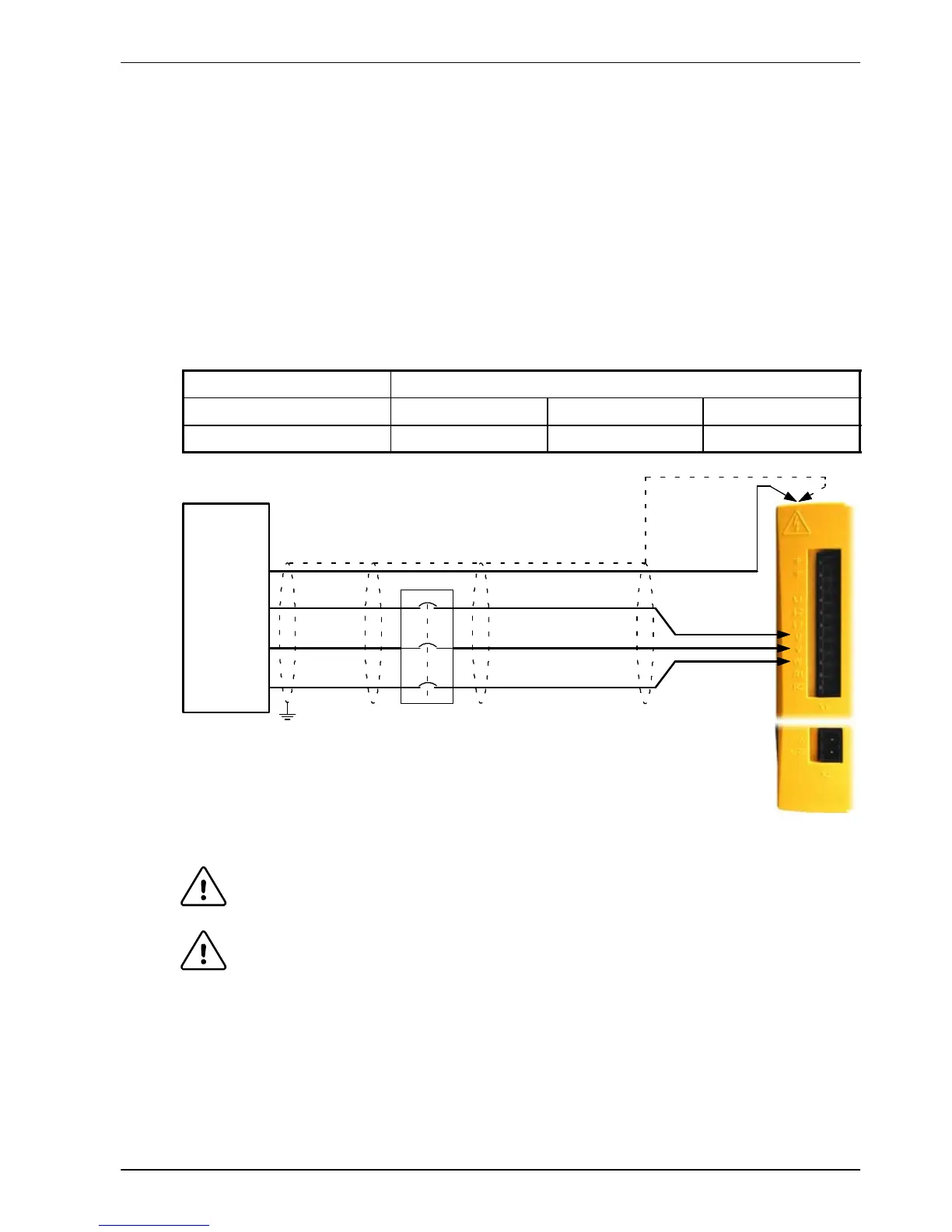

3.5 Motor connections

MicroFlex will operate with a large number of brushless servo motors. For information on

selecting Baldor servo motors please see the sales brochure BR1202, available from your

local Baldor representative. The motor must be capable of being powered by an inverter PWM

output - see section 8.1.3 for details. The motor can be connected directly to the MicroFlex or

through a motor contactor (M-Contactor). The motor outputs are conditionally short-circuit

proof. Motors should ideally have a minimum inductance of 1mH per winding; for motors with

lower inductance an output reactor may be fitted in series with the motor.

When using a Baldor motor, the parameters for managing motor overloads are configured

automatically by the Commissioning Wizard (see section 6.2.3). If they need to be changed, or

you are using an alternative motor, use the Parameters tool in Mint WorkBench (see section

6.3.2).

Location

Connector X1

AC supply volt a ge 115VAC, 1Φ 230VAC, 1Φ 230VAC, 3Φ

Output volta ge range 0-115VAC, 3Φ 0-230VAC, 3Φ 0-230VAC, 3Φ

Unshielded

lengths should

be as short as

poss ible.

V

W

U

Motor

To earth/ground outer

shield, use 360°

clamp connec ted to

top of drive

Optional motor

circ uit contactors

To earth/ground

outer shi eld,

use 360° cl amp

connec ted to

back plane

Earth

Connect m otor

earth/ground

to protective

earth on top of

drive

Figure 7 - Motor connections

CAUTION: Do not connect supply power to the MicroFlex UVW outputs. The

MicroFlex might be damaged.

CAUTION: The motor leads U, V and W must be connected to their corresponding U,

V or W terminal on the motor. Misconnection will result in uncontrolled

motor movement.

The motor power cable must be shielded for CE compliance. The connector or gland used at

the motor must provide 360 degree shielding. The maximum recommended cable length is

30.5m (100ft).

Note: For CE compliance the motor earth/ground should be connected to the drive

earth/ground.

Loading...

Loading...