www.baldormotion.com

Input / Output 5-17MN1919

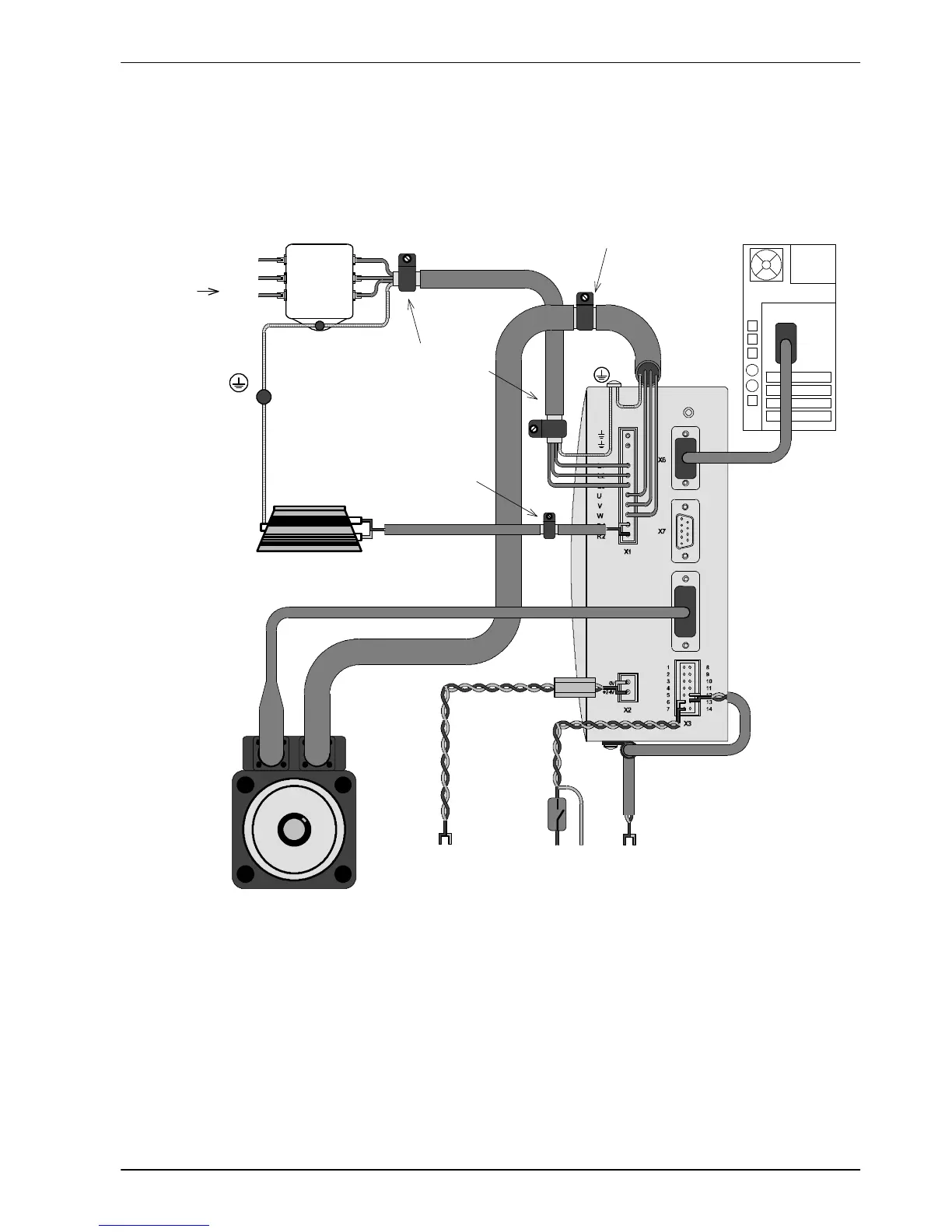

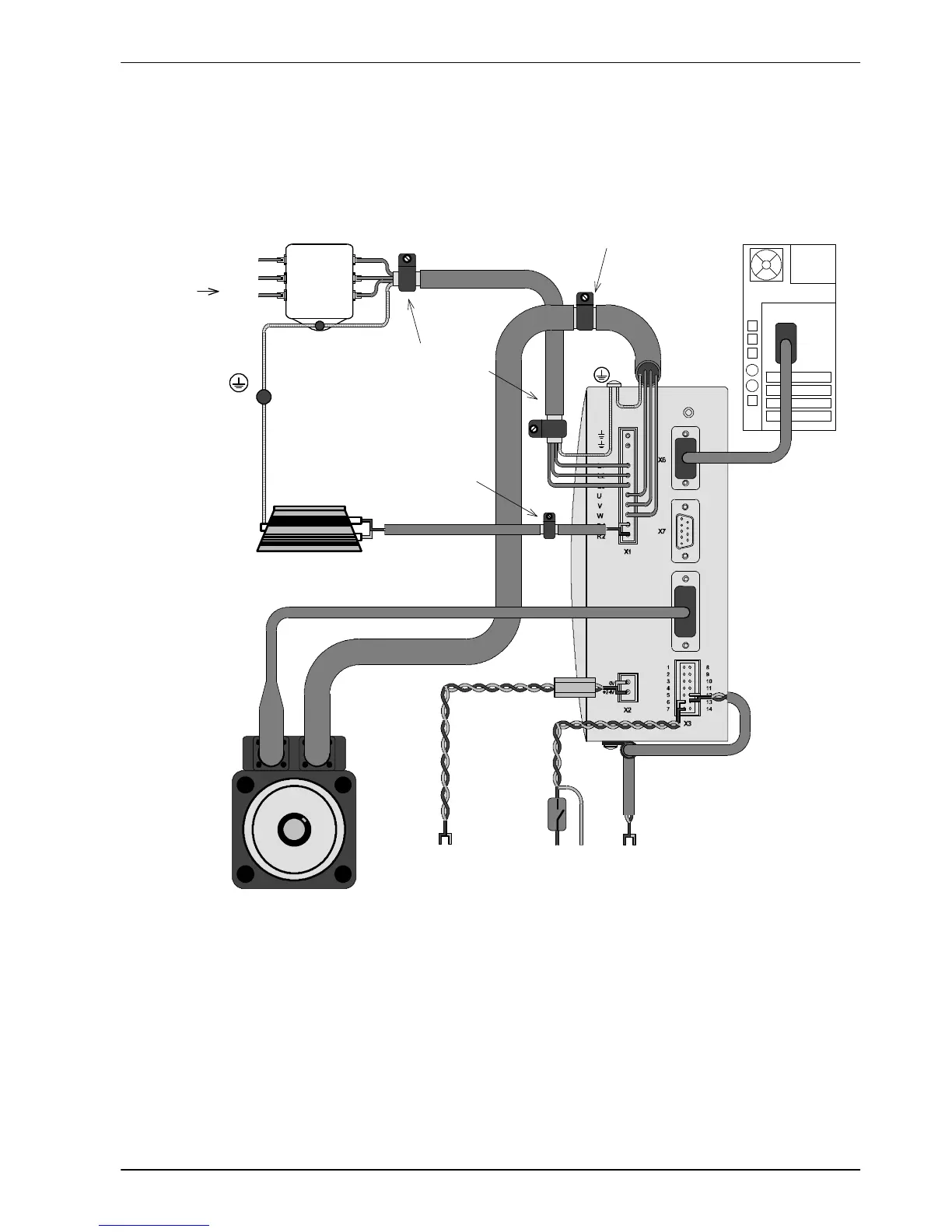

5.5 Connectio n summary - recommended system wiring

As an example, Figure 42 shows the recommended wiring necessary for the MicroFlex to

control a motor , while conforming to the EMC requirements for ‘industrial’ environments.

COM

Host PC

AC power

Motor power U V W

Serial

communication

Control circuit supply.

Use twisted pair cable

with a ferrite sleeve

(see section 3.4.8).

Motor

+24V

H The MicroFlex should be mounted on an earthed metal bac kplane.

H Ensure cables do not obstruct airflow to the heatsi nk.

H Motor represents a typical Baldor BSM motor. Linear motors may al so be controlled by MicroFlex.

H Conductive shield earth/ground clamps are not supplied.

H When using single phase supplies it may be necessary to reverse the AC power filter - see section 3.4.7.2.

0V

Filter

L1

L2

L1

L2

L3

Star

point

L1

L2

L3

L3

Connect m otor

power cable shield

to metal backplane

using conduc tive

shield clamp

Drive enable

input

+24V 0V

PE

From

fuses

AC power in

Motor feedback

Regen

Shielded twisted pair, cl amped to

metal backplane near drive using

conduc tive shield earth/ground

clamp (see sections 3.6 and C.1.7).

Connect AC power cable shield to

metal backplane using conduc tive

shield clamp (see section C.1.7).

Demand input: ±10V analog i nput

(shown) or +5V step and direction

inputs. Use shielded twisted pair(s) for

demand i nput(s). Connect c able shield

to the bottom of MicroFlex usin g

conduc tive shiel d earth/ground clamp.

Optional regen resistor

(Dynamic brake)

Figure 42 - Recommended system wiring

Loading...

Loading...