3. On the adjustment at the bottom of the screen, adjust the slider and click the Manual Trigger button. When adjusted

correctly, the annotations should turn yellow, and the icon in the upper-right of the screen should indicate fail.

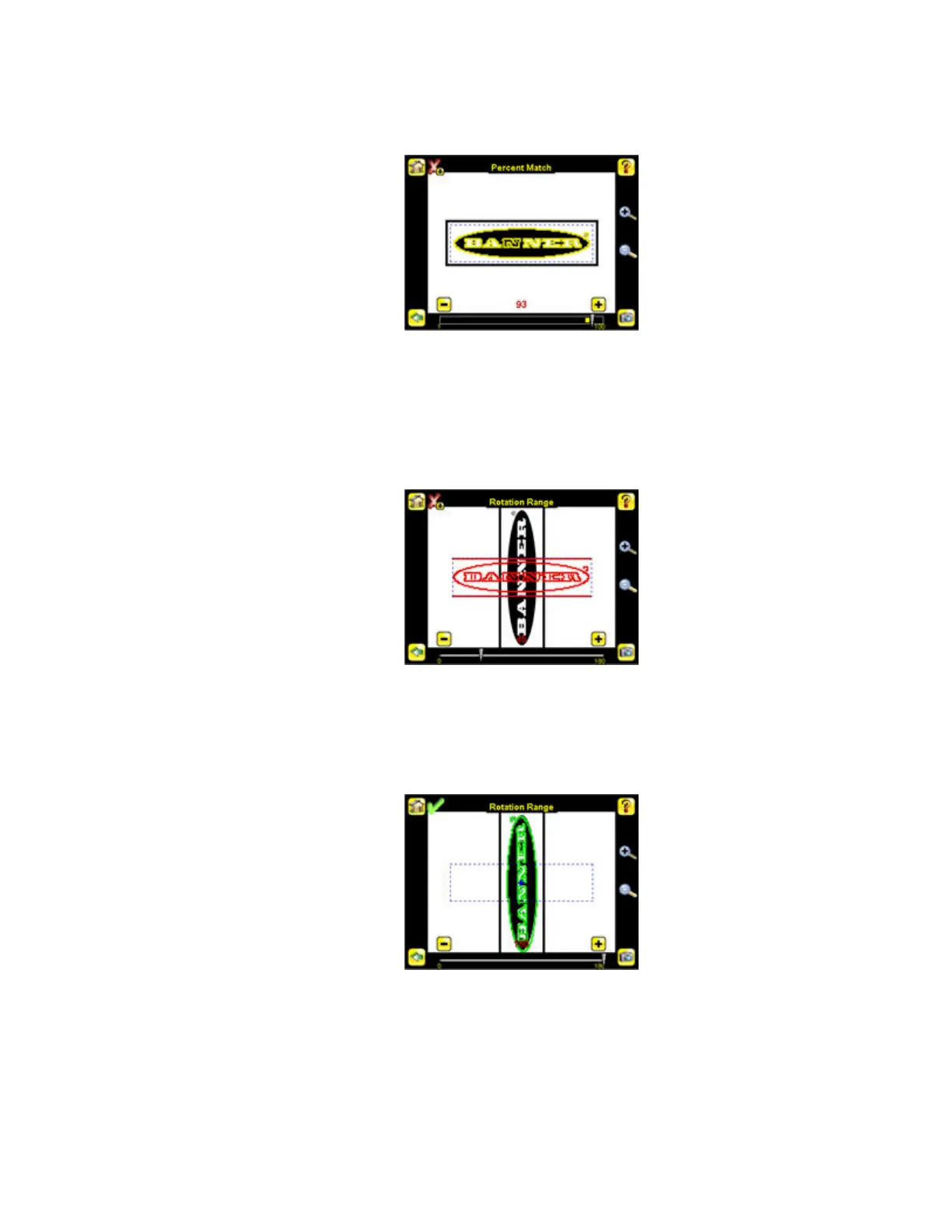

• Adjust the Rotation Range. The Rotation Range sets the expected rotation of parts or labels during an inspection. For exam-

ple, a value of 45 means that the part may rotate 45 degrees in either direction from the reference part and still pass. Move the

slider from 0 to 180 degrees. Note that the smaller the rotation range, the faster the inspection will run. To set the Rotation

Range:

1. Go to Main Menu > Inspection , and click the Rotation Range option.

2. Move the slider at the bottom of the screen to the desired rotation. If you are verifying that a label is correctly applied to a

container; that is, on straight, you will want to set a small rotation. If you want to make sure that the correct label is

present no matter how the part is oriented in the Field of View, then the rotation range will be set to its maximum (180°,

which is the setting for the Demo).

• Set the Pass Count parameter. The Minimum Pass Count is the minimum number of parts, labels, or features expected to fall

within the specified criteria; the Maximum Pass Count is the maximum number expected to fall within the specified criteria.

These settings are used to determine the pass or fail result of the inspection.

1. Go to Main Menu > Inspection , and click the Pass Count option.

iVu Series Image Sensor

52 www.bannerengineering.com - tel: 763-544-3164 Rev. E

Loading...

Loading...