2

-

13

42hW-201601

CHAPTER 2 ENGINE3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

2

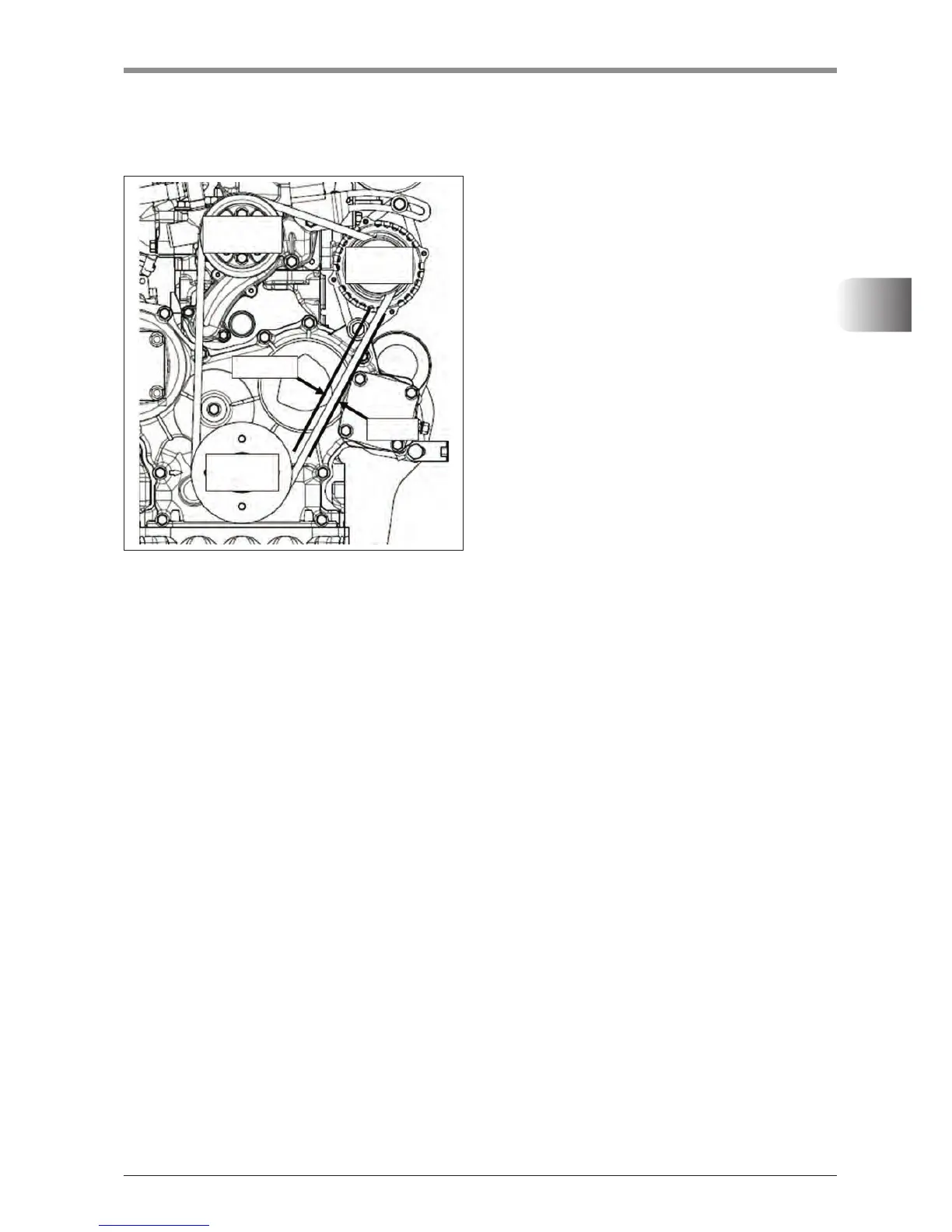

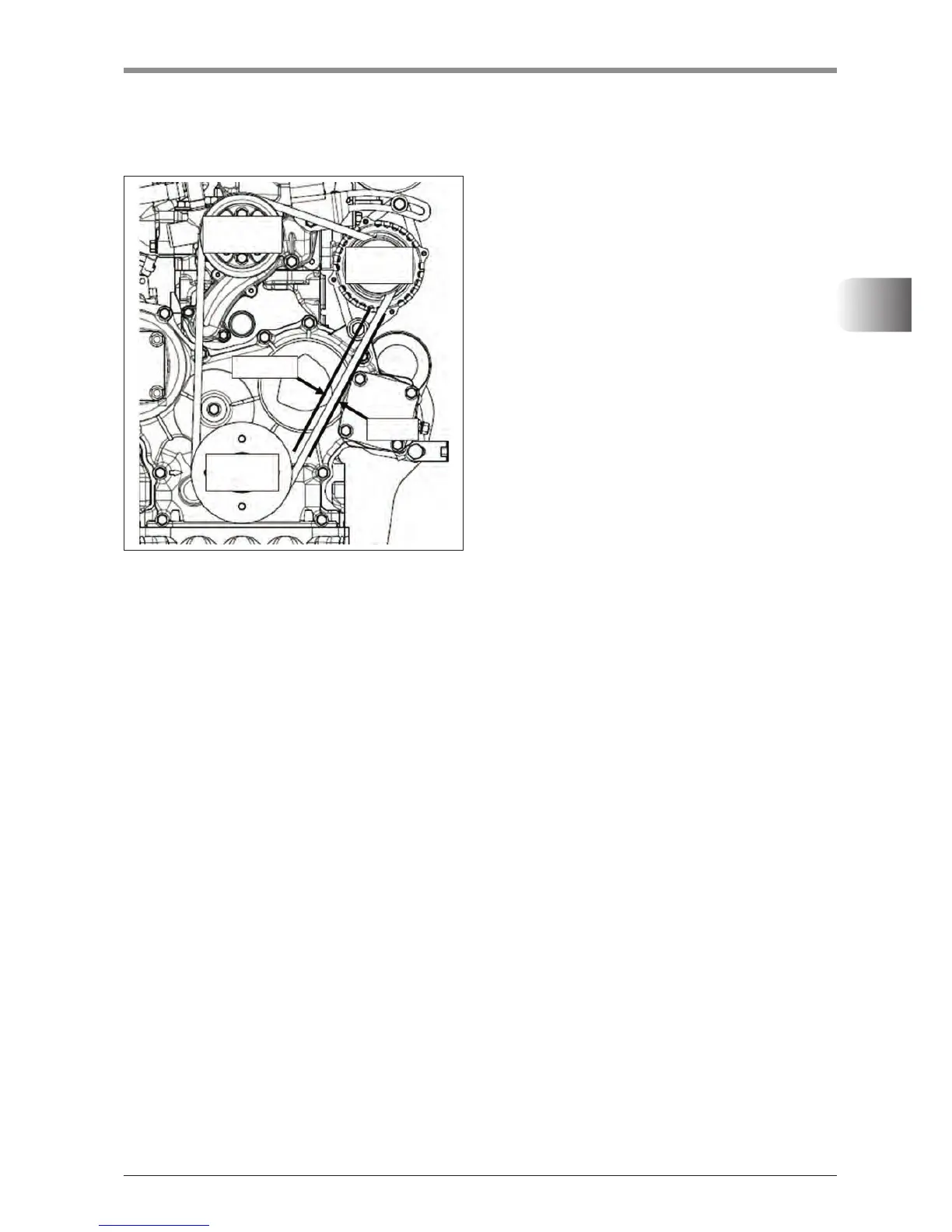

2.2.5 V-BELT.

Too much of fan belt tension accelerates wear

of the belt, in contrast, too little of belt tension

leaves the pulley idle, overheats the engine, and

no-load is generated. Adjust the belt tension as

follows.

The belt tension is 8~12mm in the case of new

part. The case which uses the belt, adjust

tension to 10~15mm.

Correct adjustment exists when the belt can be

pushed inward about 10~15mm with 10kgf (22Ib)

thumb pressure exerted midway between the

pulleys. Check if there is oil, grease, any damage

in the belt.

Replace the belt if it is cracked or frayed.

Replace the belt if tegument is worn out or some

pieces are detached.

•

•

•

•

•

K25W234A

2.2.6 EVERY 50HRS CHECK

1. Replace the lubricating oil and oil lter: Replace

the lubricating oil and oil lter at the rst 50hrs.

2. Check the tension of the V-belt.

2.2.7 CHECK EVERY 250HRS

1. Replace the lubricating oil and oil lter: Replace

the lubricating oil and oil lter every 250 hrs after

replacing it at rst 50 hrs.

2. Check & cleaning the radiator pin.

3. Cleaning the air cleaner.

4. Check the tension of the V belt.

2.2.8 CHECK EVERY 500HRS

1. Replace the fuel lter: Replace the fuel lter every

500 hrs after replacing it at rst 50 hrs.

2. Replace the air cleaner elements.

2.2.9 CHECK EVERY 1,000HRS

1. Check & correct the injection pressure of injector

and the spray condition (see section 5.2.)

2. Correcting the valve clearance (see section

4.3.23)

2.2.10 CHECK EVERY 2,000HRS

1. Cleaning & maintenance of the coolant path: Parts

related coolant path such as radiator, water pump,

cylinder block and head, oil cooler etc. occur

cooling efficiency decrease by long-term use.

Therefore cleaning & maintenance is required.

2. Check & replace the fuel pipe and coolant pipe:

Check the hose class used in the fuel pipe or

coolant pipe etc, and the blazing or defected

parts replace. Although replacement timing is not

reached, hose class replace once every 2 years.

3. Rapping of intake/exhaust valve: Do maintenance

to ensure the leak tightness of the cylinder head.

4. Correct the injection timing and check& correct

the injection pump: see section 4.3.11.

Loading...

Loading...