72 1019572 REV. 03

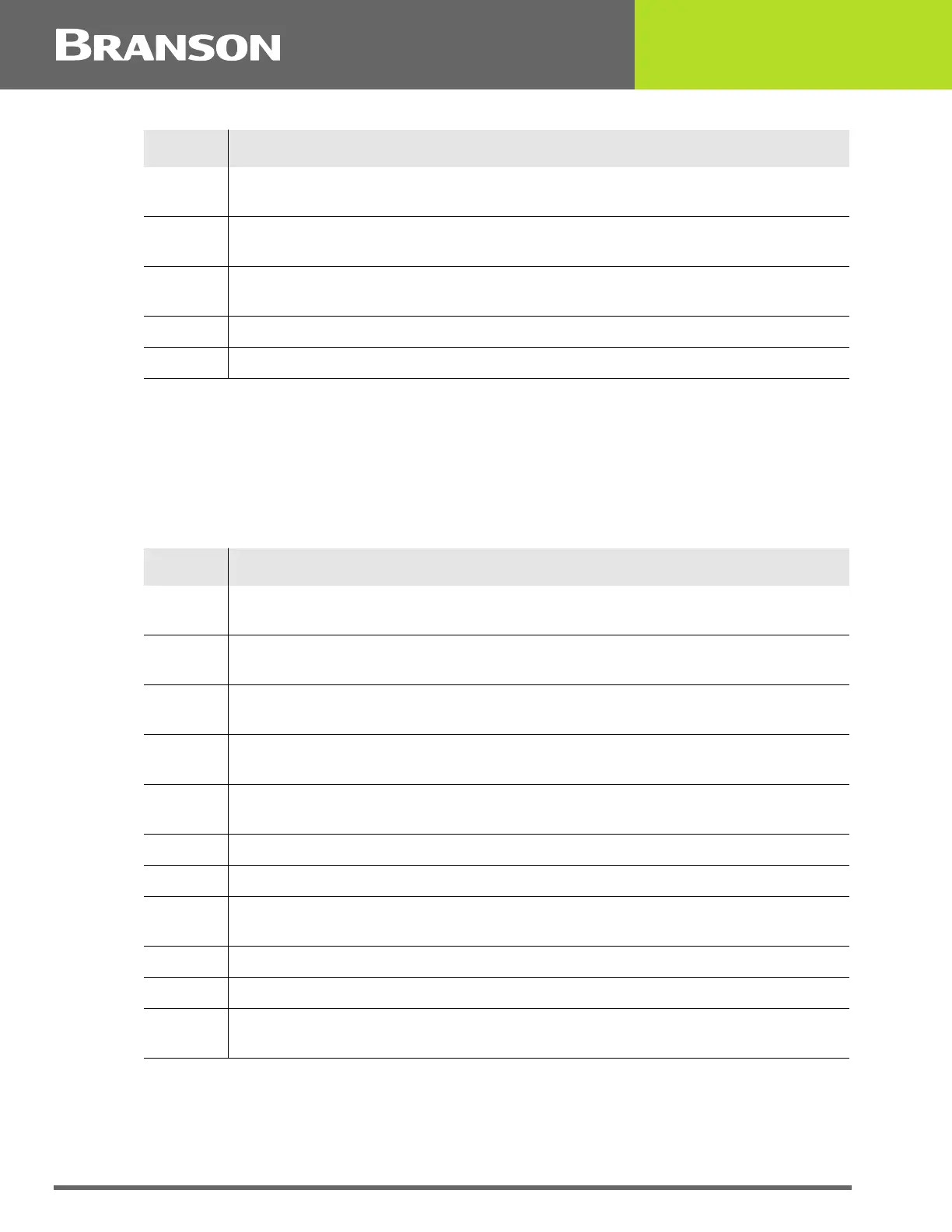

4.8.4 For a 40 kHz System

3

Install the threaded stud into the top of the booster; torque to 290 in-lbs,

32.76 Nm, and let cure for 30 minutes.

4

Install the threaded stud into the top of the horn; torque to 290 in-lbs,

32.76 Nm, and let cure for 30 minutes

5

Install a single Mylar washer (matching the size of the washer to the stud) to

each interface.

6 Assemble the converter to the booster and the booster to the horn.

7 Torque to 185 in-lbs, 21 Nm.

a. Loctite is a registered trademark of Henkel Corporation, U.S.A.

Table 4.14 Assemble the Acoustic Stack (for a 30 kHz System)

Step Action

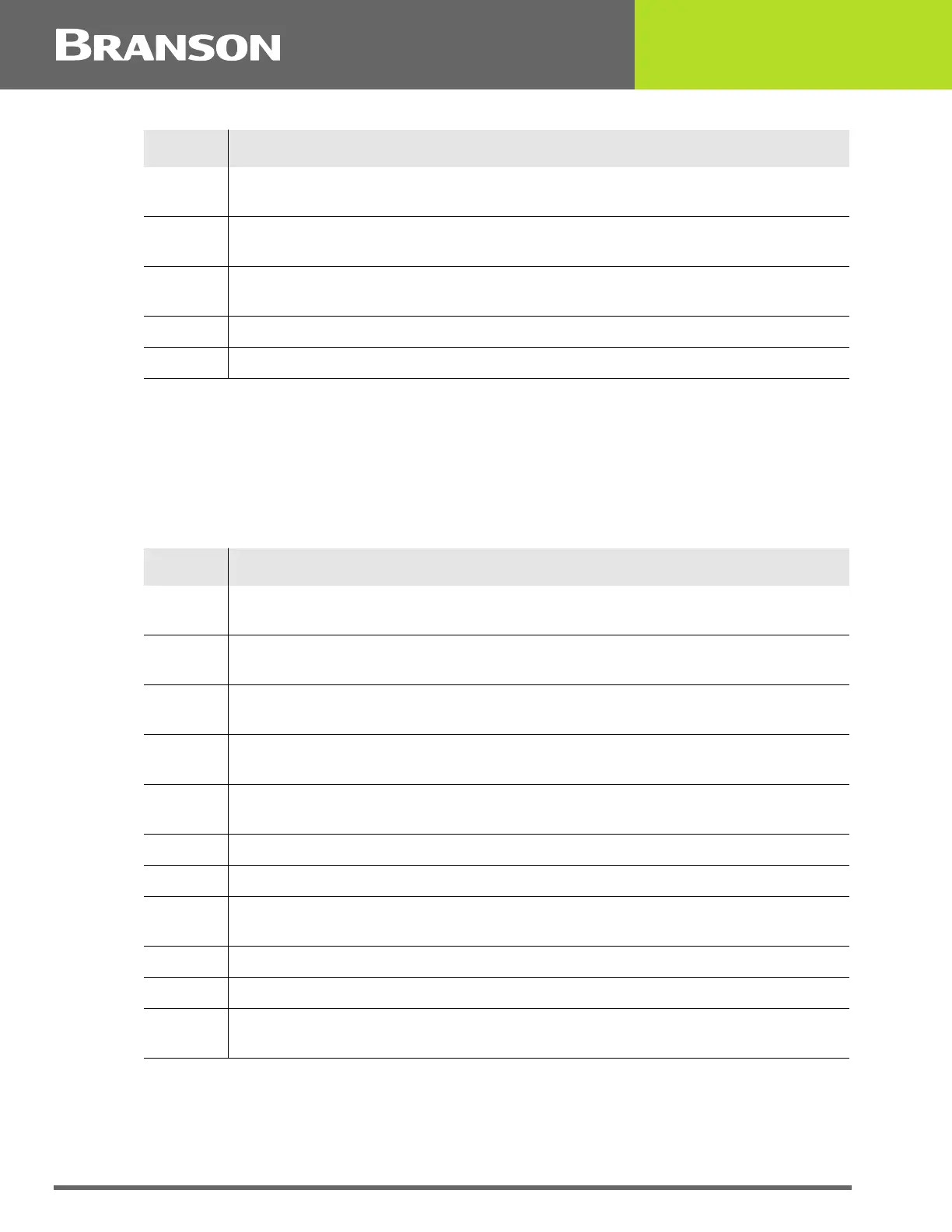

Table 4.15 Assemble the Acoustic Stack (for a 40 kHz System)

Step Action

1

Clean the mating surfaces of the converter, booster, and horn. Remove any

foreign material from the threaded holes.

2

Apply a drop of Loctite 290 threadlocker (or equivalent) to the studs for the

booster and horn.

3

Install the threaded stud into the top of the booster; torque to 70 in-lbs,

7.91 Nm, and let cure for 30 minutes.

4

Install the threaded stud into the top of the horn; torque to 70 in-lbs,

7.91 Nm, and let cure for 30 minutes.

5

Coat each interface surface with a thin film of silicon grease – but do not

apply silicon grease to a threaded stud or tip.

6 Screw the converter to the booster.

7 Torque to 95 in-lbs, 10.73 Nm.

8

Slide the booster/horn assembly into the adapter sleeve. Screw on the

adapter sleeve ring nut and leave loose.

9 Screw the booster onto the horn.

10 Repeat Step 7.

11

Securely tighten the adapter sleeve ring nut with the spanner wrenches

shipped with the sleeve assembly.

Loading...

Loading...