Utility Requirements

68 H157655_1_008

8.7 Emergency Ventilation During Installation and Quenches

Due to the large amount of liquid helium contained in the magnet, an emergency exhaust

system may be required to prevent O

2

depletion during a magnet quench.

Likewise, during the installation, refilling and cooling of superconducting magnets, large

volumes of nitrogen or helium gases may be generated under certain conditions. Although

these gases are inert, if generated in large enough quantities, they can displace the oxygen

in the room causing potential danger of suffocation.

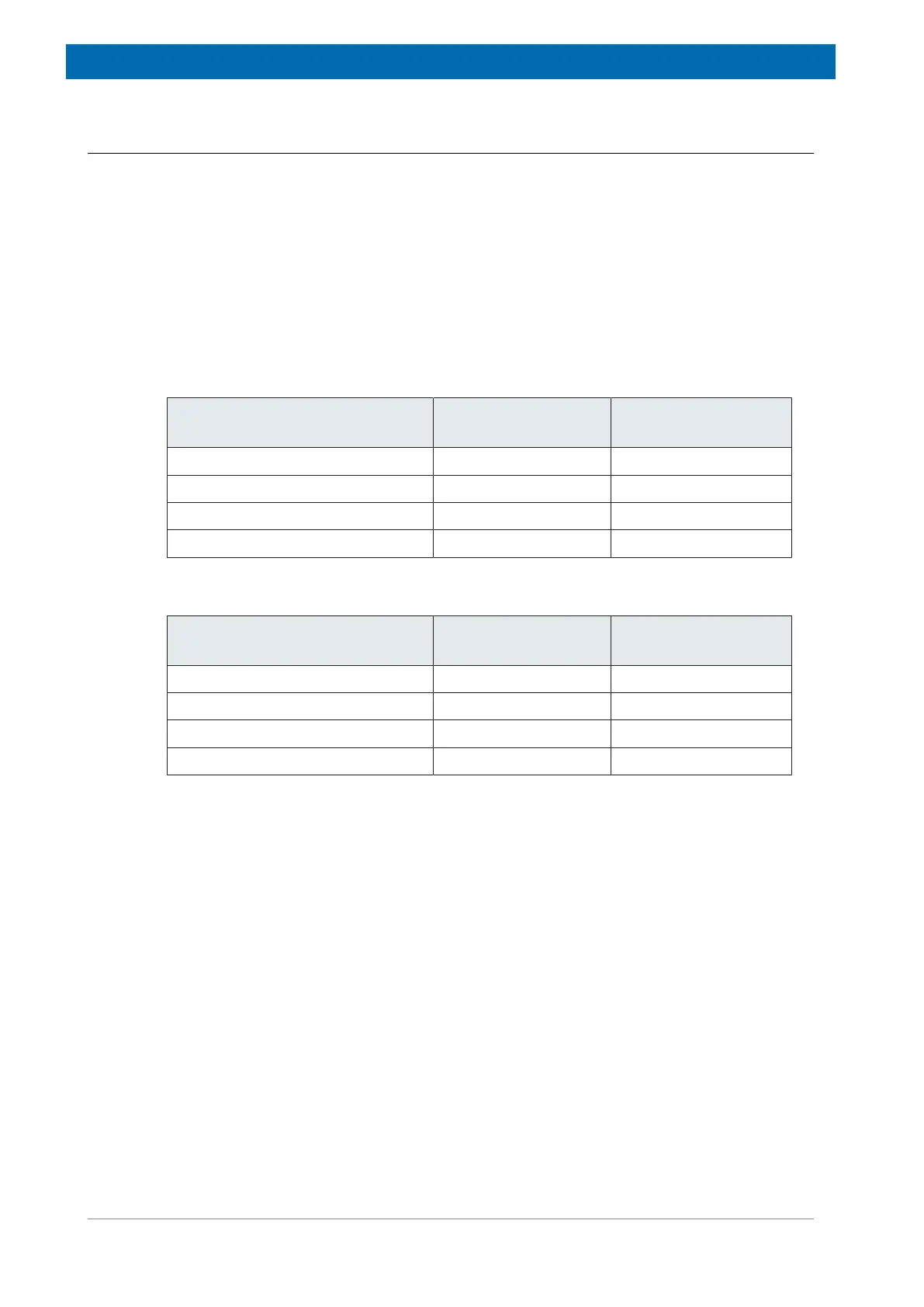

The following table lists the maximum helium capacity and the typical gas flow rates for

helium gas during a quench for current magnet systems. Generally, the gas flow rate is equal

to half the volume in one minute.

Total Volume of Gas and Maximum Helium Gas Flow

Magnet Type Total Volume of He

Gas (m

3

)

Maximum He Gas

Flow (m

3

/min.)

400/54 Ascend Aeon 196.7 98.35

500/54 Ascend Aeon 182.0 91.0

600/54 Ascend Aeon 262.5 131.25

700/54 Ascend Aeon 230.3 115.15

Table8.6: Total Gas Volume and Maximum He Gas Flow: Standard Bore 54 mm

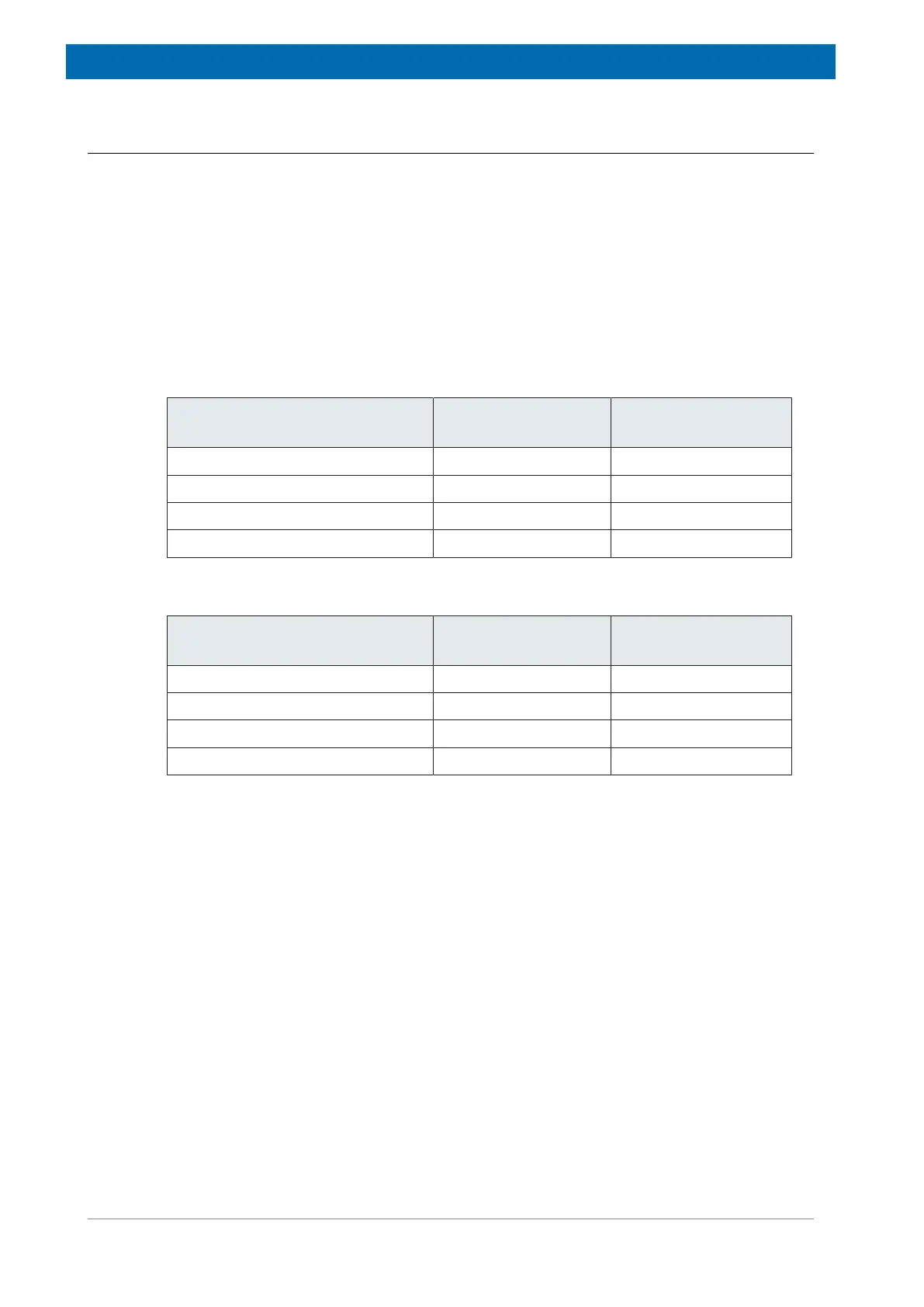

Magnet Type Total Volume of He

Gas (m

3

)

Maximum He Gas

Flow (m

3

/min.)

400/89 Ascend Aeon 269.5 134.75

500/89 Ascend Aeon 262.5 131.25

600/89 Ascend Aeon 225.4 112.7

700/89 Ascend Aeon 236.6 118.3

Table8.7: Total Gas Volume and Maximum He Gas Flow: Wide Bore 89 mm

Regarding the emergency gas exhaust, important considerations include, but are not limited

to, the following:

• Amount of liquid helium: Taking the 750 WB US

2

magnet as an example, the total

amount of liquid helium is 473 liters. In case of a quench, the liquid transforms into gas

and expands by a factor of 740. Therefore, the total amount of helium evaporated gas in

case of a quench will be ca. 350 m

3

(12,360 ft

3

).

• Maximum helium gas flow: The maximum flow of helium gas is calculated on the

assumption that half of the volume of liquid evaporates in 1 minute, thus the maximum

flow would be 175 m

3

(6,180 ft

3

) for the 750 WB US

2

magnet. The gas should be removed

from the room immediately through an emergency exhaust system.

• O

2

level sensors: Oxygen level sensors are required to detect low O

2

levels within the

laboratory for each system. One sensor is needed above the magnet for detecting low O

2

levels due to He gas exhaust in case of a quench or during He fills. An additional sensor is

needed close to the floor for detecting low O

2

levels due to N

2

gas exhaust during magnet

cooling or regular N

2

fills. In case of placing the magnet inside a pit, a third sensor is

needed inside a pit to detect low O

2

levels from N

2

gas.

Loading...

Loading...