25

Installation and wiring

Type 8228

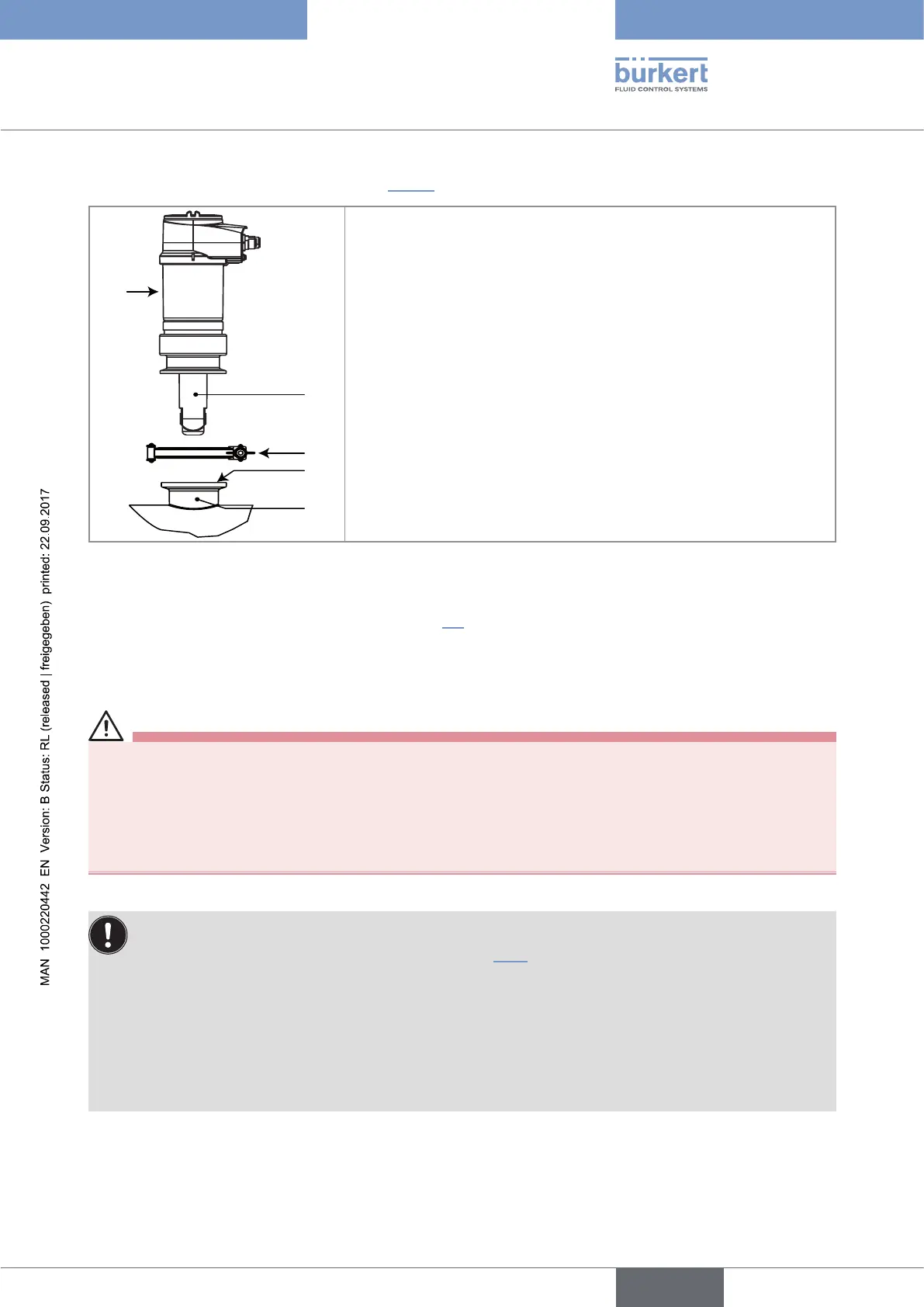

→ Install the device in the fitting as shown in Fig. 11.

→ Select a seal (mark 4) that is compatible with the 2'' clamp con-

nection of the device and with the fluid.

→ Put the seal (mark 4) on the fitting (mark 5).

→ Insert the device (mark 1) in the fitting (mark 5):

- the electrical connections must be parallel to the pipe,

- the sensor (mark 2) must be positioned in the fluid vein.

→ Tighten the clamp collar (mark 3) by hand.

Fig. 11: Installation of a 8228 with 2'' clamp connection in the pipe

→ Wire the device according to instructions in chap. 8.4.

8.4 Wiring the device

DANGER

Risk of injury due to electrical voltage.

▶ Shut down the electrical power source of all the conductors and isolate it before carrying out work on the

system.

▶ All equipment connected to the device shall be double insulated with respect to the mains according to the

standard IEC 61010-1:2010.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

• Use a filtered and regulated 12-36 V DC power supply.

• Make sure the installation is equipotential (see chap. 8.4.2).

• Use shielded cables with a temperature limit of 80 °C minimum.

• Do not install the connection cables near high voltage or high frequency cables; If this cannot be

avoided, observe a min. distance of 30 cm.

• Protect the power supply of the device with a 100 mA time-delay fuse and a switch.

• Protect the power supply of each transistor output with a 750 mA fuse.

English

Loading...

Loading...