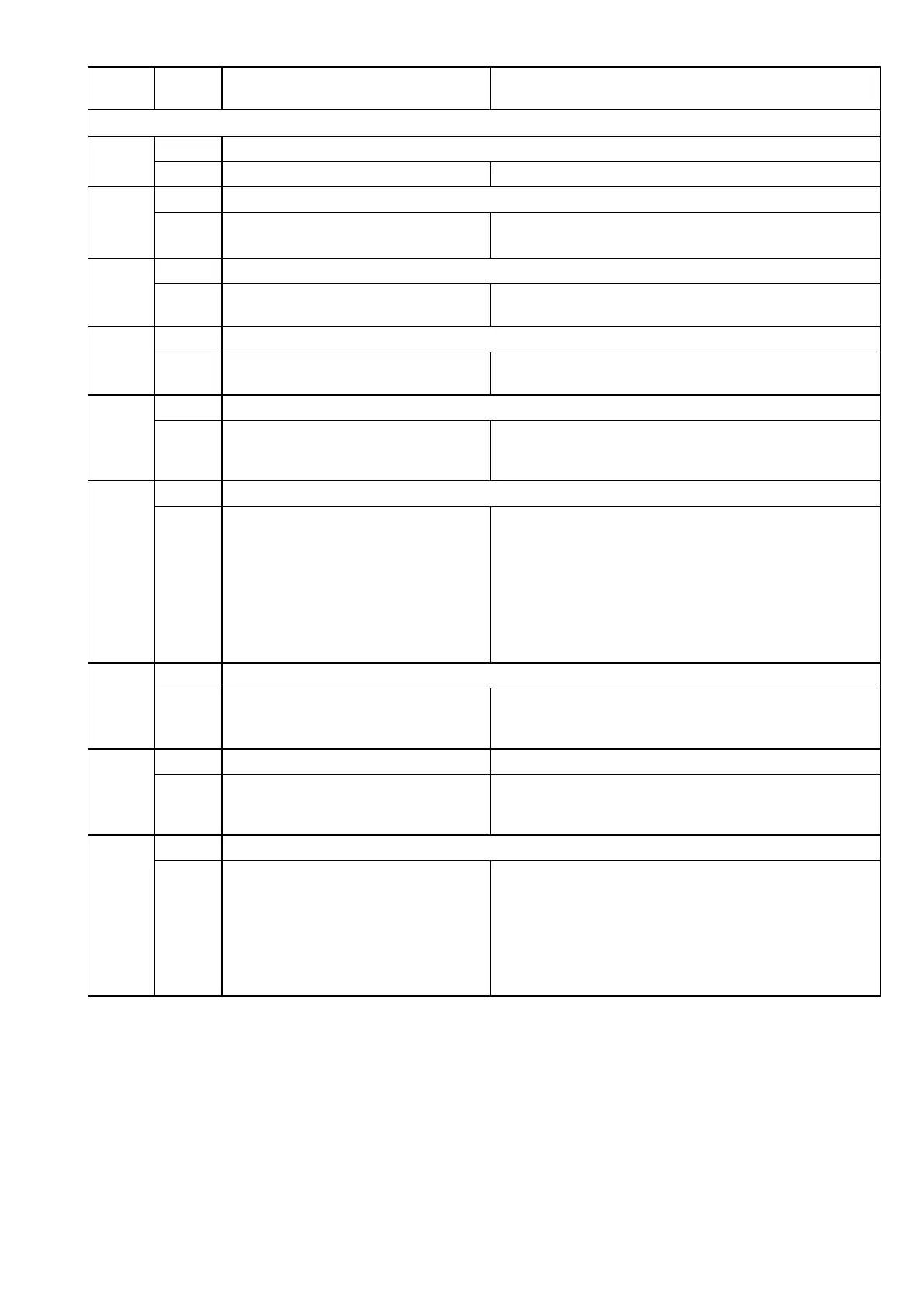

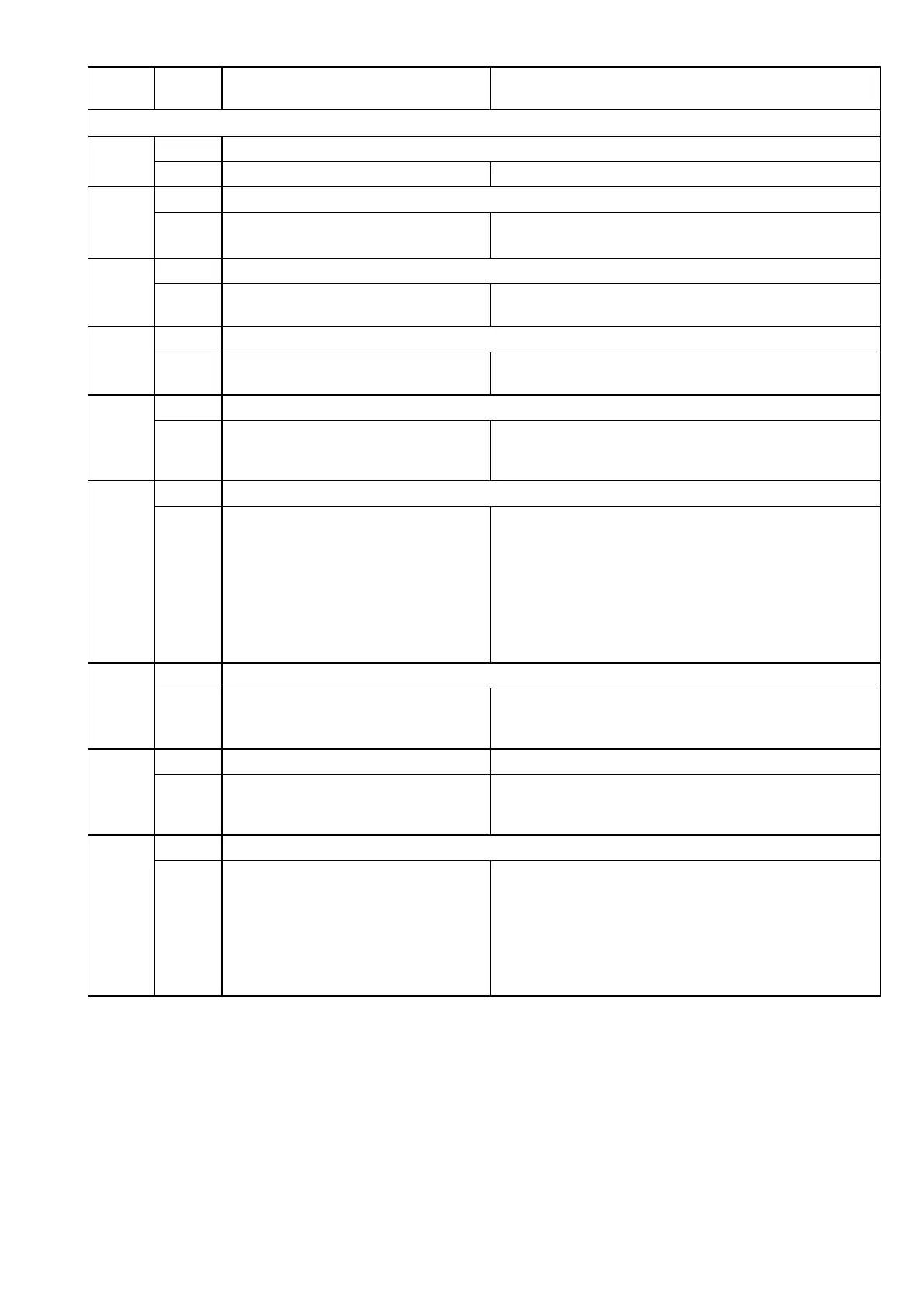

62-61753-21

53 BOX TEMP OUT-OF-RANGE (Continued)

Check Refrigerated Compartment Doors

a. Inspect all box doors.

Must be closed, no air leakage.

a. Initiate Manual Defrost Cycle.

Must terminate automatically.

All ice cleared from all evaporator coils.

Check For Any Shutdown Alarm(s)

a. Check the Alarm List for any Shut-

down Alarms.

Alarm conditions must be corrected and the alarm

cleared to continue.

Check For Low Refrigerant Pressure Alarm

Alarm conditions must be corrected and the alarm

cleared to continue.

a. Check refrigerant level in the re-

ceiver.

Generally, level should be between upper & lower sight

glasses with a refrigerated compartment temperature

of 1.0°C (35°F) or lower. refer to Section 8.5.4

a. Install Manifold Test Set and check

and compare compressor dis-

charge & suction pressures with

those shown on the microproces-

sor.

Suction & Discharge Pressures must have the same

reading on gauges & on microprocessor display.

Pressures must be in the normal range for ambient &

refrigerated compartment temperature conditions.

NOTE: Microprocessor suction (CSP) and evapora-

tor (EVOP) pressure readings have a maximum

value of 7.5 bar (100 psig). The actual suction pres-

sure must be lower in order to perform this test.

a. Check evaporator section, return

air bulkhead, air chute, cleanliness

of evap. coil and airflow.

a. Clear Active Alarm list, then run

Pretrip & check for any new

alarms.

Any active alarms must be corrected and cleared be-

fore proceeding.

a. Read Delta-T from Unit Data List.

In Cool, the Delta-T reading must be greater than -

0.56°C (-1°F).

Note for Delta-T readings a higher number after the "-"

sign is "greater than". For example, -3°C is greater

than -2°C.

In Heat the Delta-T must be greater than 0 (SAT must

be higher than RAT).

Loading...

Loading...