62-61753-21

55 CHECK DEFROST AIR SWITCH

TRIGGER-ON: The defrost air switch has called for a defrost cycle within 8 minutes of a defrost ter-

mination for 2 consecutive defrost cycles. (The air switch contacts were closed continuously for

15 seconds before the defrost cycle was started.)

UNIT CONTROL: Engine and standby operation: alarm only. While this alarm is active, the defrost air

switch will NOT be used to initiate a defrost cycle; however the Defrost Timer will initiate a defrost cy-

cle 90 minutes after the alarm comes on, and the manual defrost switch will remain operative.

RESET CONDITION: Auto Reset when defrost cycle terminates correctly, and the air switch does not

call for a defrost cycle within the 8 minutes following defrost termination, or alarm may be manually

reset via keypad or by turning the unit off, then back on again.

NOTE: Follow the steps below until a problem is found. Once a repair or correction has been made, the active

alarm should clear itself (refer to reset condition above). Operate the unit through the appropriate modes to see if

any active alarm occurs. Continue with the steps below as necessary.

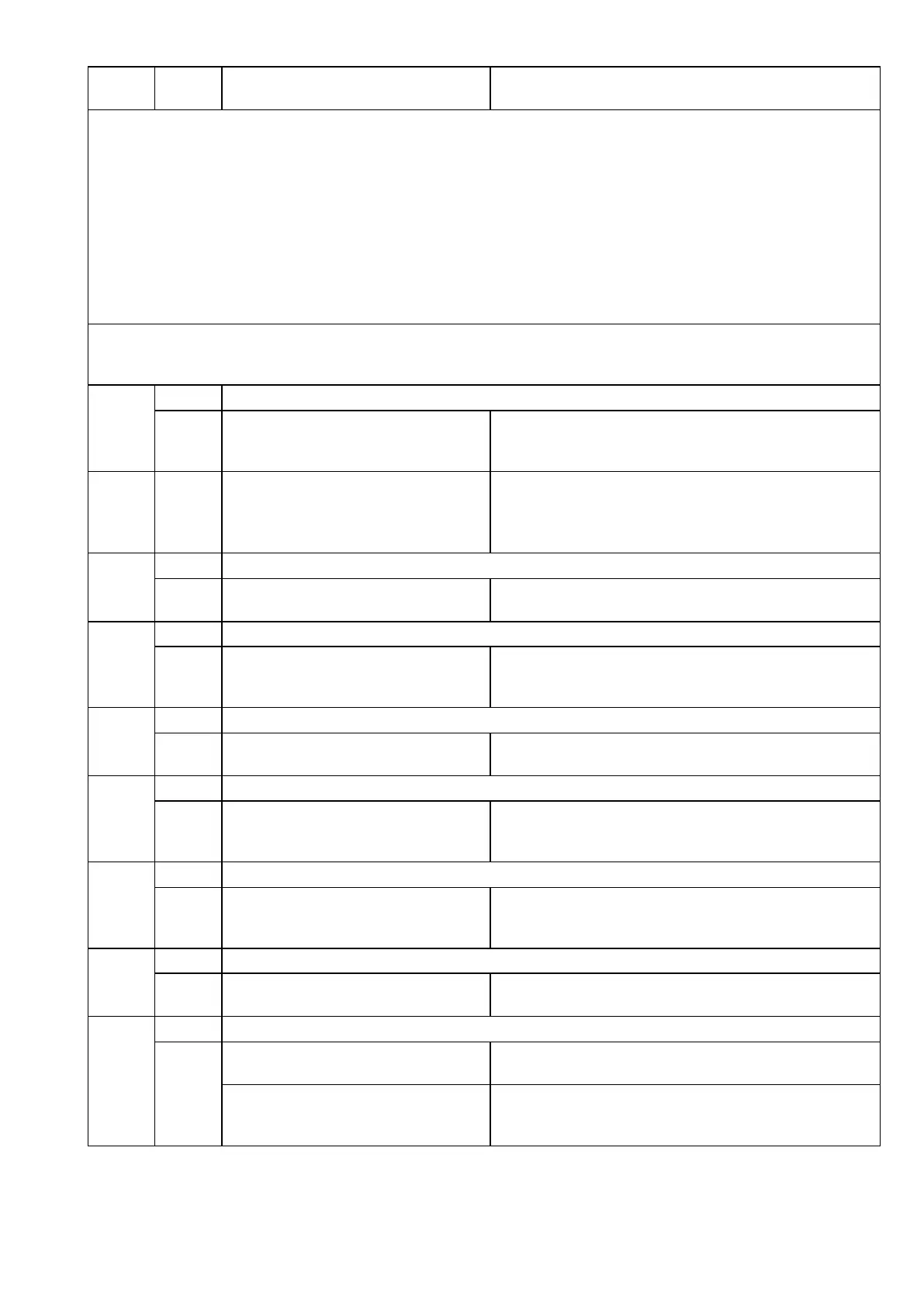

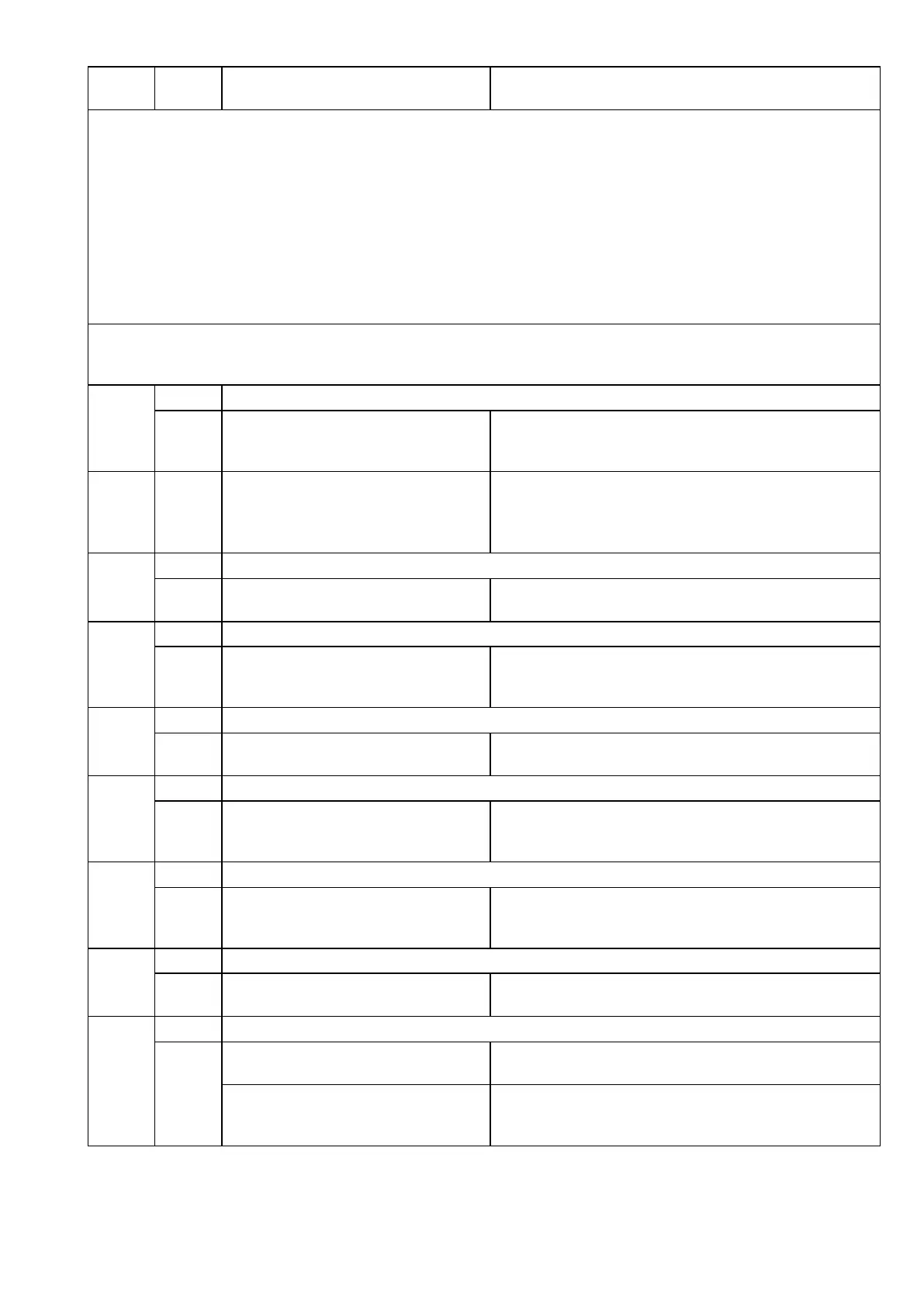

a. Inspect switch & connector pins &

terminals. (See wiring schematic

Section 10.)

No physical damage to harness.

No damaged or corroded pins.

b. Check switch circuit

Check for voltage at the switch

plug between pins B (+) and A

(ground).

Energize circuit (refer to Note 2 Page 7-2).

Voltage should be approximately 12 VDC.

a. Check switch operation and set-

ting.

a. Inspect air hoses to switch.

No kinks or other obstructions.

No holes.

Connected to correct nipple.

Check Condition Of Evaporator

a. Visually inspect evaporator follow-

ing defrost.

Coil must be clean and cleared of ice or any other ma-

terial.

a. Clear Active Alarm list, then run

Pretrip & check for any new

alarms.

Any active alarms must be corrected and cleared be-

fore proceeding.

Check Evaporator Pressure Drop

a. Check pressure reading by con-

necting Magnehelic Gage to switch

tubing.

Check evaporator section, return air bulkhead, air

chute, cleanliness of evap. coil and airflow. Refer to

Section 9.4.10

Check Evaporator Contactor

a. Check Evap Fan operation in de-

frost.

Check Condition Of Refrigerated Compartment & Load

a. Check condition of refrigerated

compartment doors & seals.

Doors must be closed, and door seals must seal and

prevent outside air from leaking in.

b. Check condition of product. If it is

warm and moist, frequent defrost

cycles can be expected.

Loading...

Loading...