62-61753-21

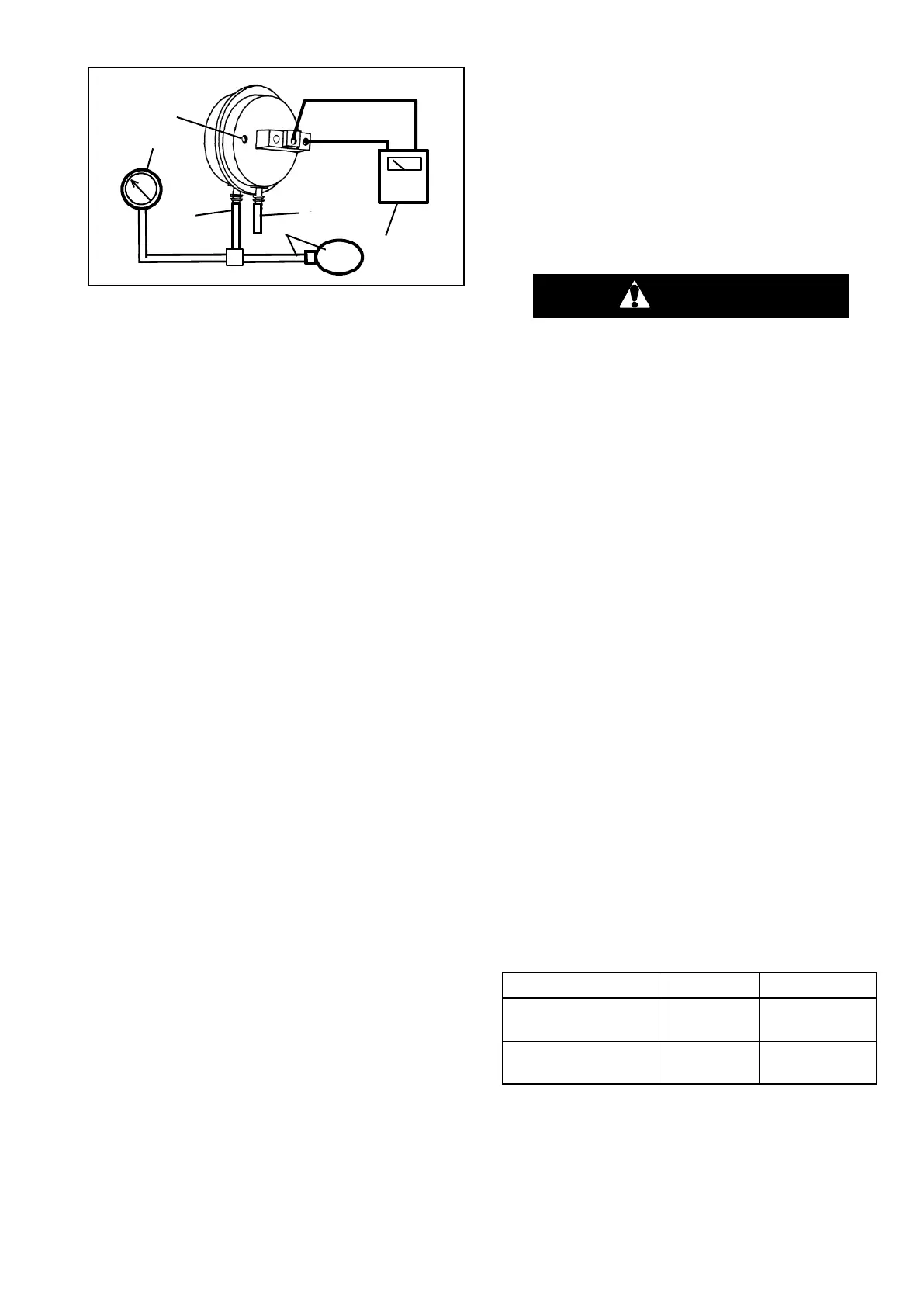

1. Ohmmeter or Continui-

ty Device

2. Adjustment Screw

(0.050” socket head

size)

3. Low Side Connection

4. Pressure Line or Aspi-

rator Bulb

(P/N 07-00177-01)

5. Magnehelic Gauge

(P/N 07-00177-00)

6. High Side Connection

Figure 8-21. Defrost Air Switch Test Setup

d. Ensure magnehelic gauge is in proper calibration.

NOTE

The magnehelic gage may be used in any po-

sition, but must be re-zeroed if position of

gauge is changed from vertical to horizontal or

vice versa. USE ONLY IN POSITION FOR

WHICH IT IS ZEROED.

e. With air switch in vertical position, connect high

pressure side of magnehelic gauge, a tee and and

aspirator to high side connection of air switch. Tee is

to be placed approximately half-way between gauge

and air switch or an improper reading may result.

(See Figure 8-20)

f. Attach an ohmmeter to the air switch electrical con-

tacts to check switch action.

NOTE

Use a hand aspirator (P/N 07-00177-01), since

blowing into tube by mouth may cause an in-

correct reading.

g. With the gauge reading at zero, apply air pressure

very slowly to the air switch. An ohmmeter will indi-

cate continuity when switch actuates. The switch

contacts should close and the ohmmeter needle

move rapidly to 0. Any hesitation in the ohmmeter

indicates a possible problem with the switch, and it

should be replaced.

h. Refer to Section 2.10 for switch settings. If switch

fails to actuate at correct gauge reading, adjust

switch by turning adjusting screw clockwise to in-

crease setting or counter-clockwise to decrease set-

ting.

i. Repeat checkout procedure until switch actuates at

correct gauge reading.

j. After switch is adjusted, place a small amount of

paint or fingernail polish on the adjusting screw so

that vibration will not change switch setting.

8.7 ELECTRICAL SYSTEM COMPONENT SER-

VICE

8.7.1 Heaters

Description

The evaporator coil heaters and drain pan heater are

energized through the power supply or engine driven

AC generator. They are used in the defrost and heat

modes.

Replacing Heaters

Be aware of HIGH VOLTAGE supplied by

the generator as the unit may start auto-

matically. Before servicing the unit, ensure

the START/RUN-OFF switch is in the OFF

position. Also disconnect the power plug

and negative battery cable. NEVER dis-

assemble the generator: HIGH MAGNETIC

FIELD INSIDE!

a. Remove the evaporator access panel.

b. Determine which heater(s) need replacing by check-

ing resistance of each heater rod (refer to section

2.11).

c. Remove hold-down clamp securing heaters to coil

or pan.

d. Lift the "U" portion of the heater (with the opposite

end down and away from coil). Move heater left (or

right) enough to clear the heater end support.

8.7.2 Evaporator Fan & Motor

The evaporator fan is of the blower type and circulates

air throughout the refrigerated compartment. The air is

drawn through the evaporator coil where it is either

heated or cooled and then discharged out the nozzles

into the compartment. The fan motor bearings are

factory lubricated and do not require additional grease.

For electrical data, refer to section 2.14.

NOTE

The evaporator blower assemblies are differ-

ent and rotate in opposite directions. Refer to

Table 8-4 for correct identification.

Table 8-4. Blower Wheel Identification

Road Side (engine

side) Blower

Curb Side (compres-

sor side) Blower

Loading...

Loading...