10. Connect the vapour valve (F) of the R-452A

recovery bottle to the recovery machine.

The system is ready for vapour recovery.

R-452A vapour recovering

1. Open Vapour valve (F).

2. Start the Recovery machine.

3. Open hose (B) service valve

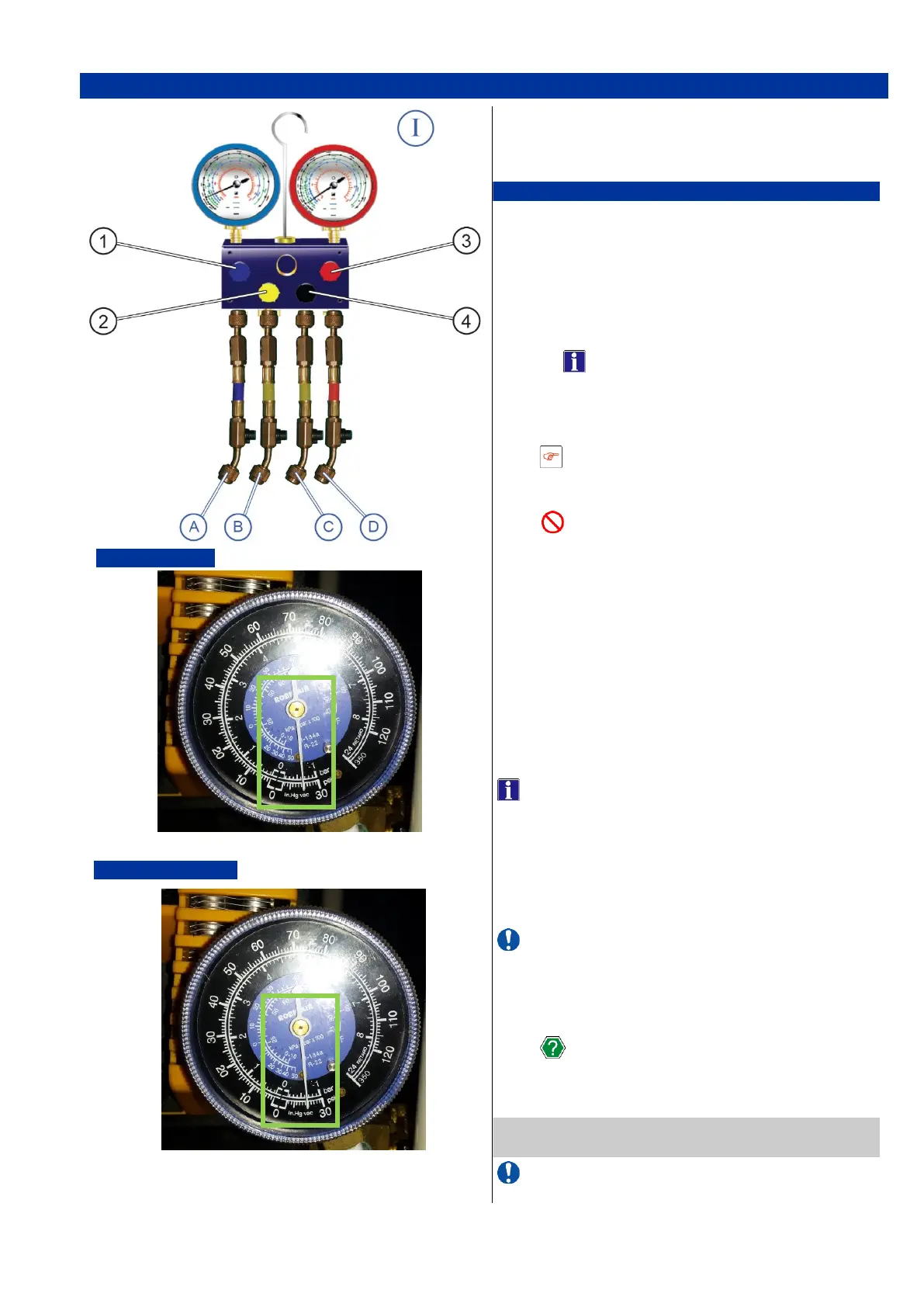

4. Open the manifold gauge valve (1,4).

The R-452A vapour is going from the com-

pressor to the R-452A recovery bottle.

All manifold gauge valves (1,2,3,4)

are opened.

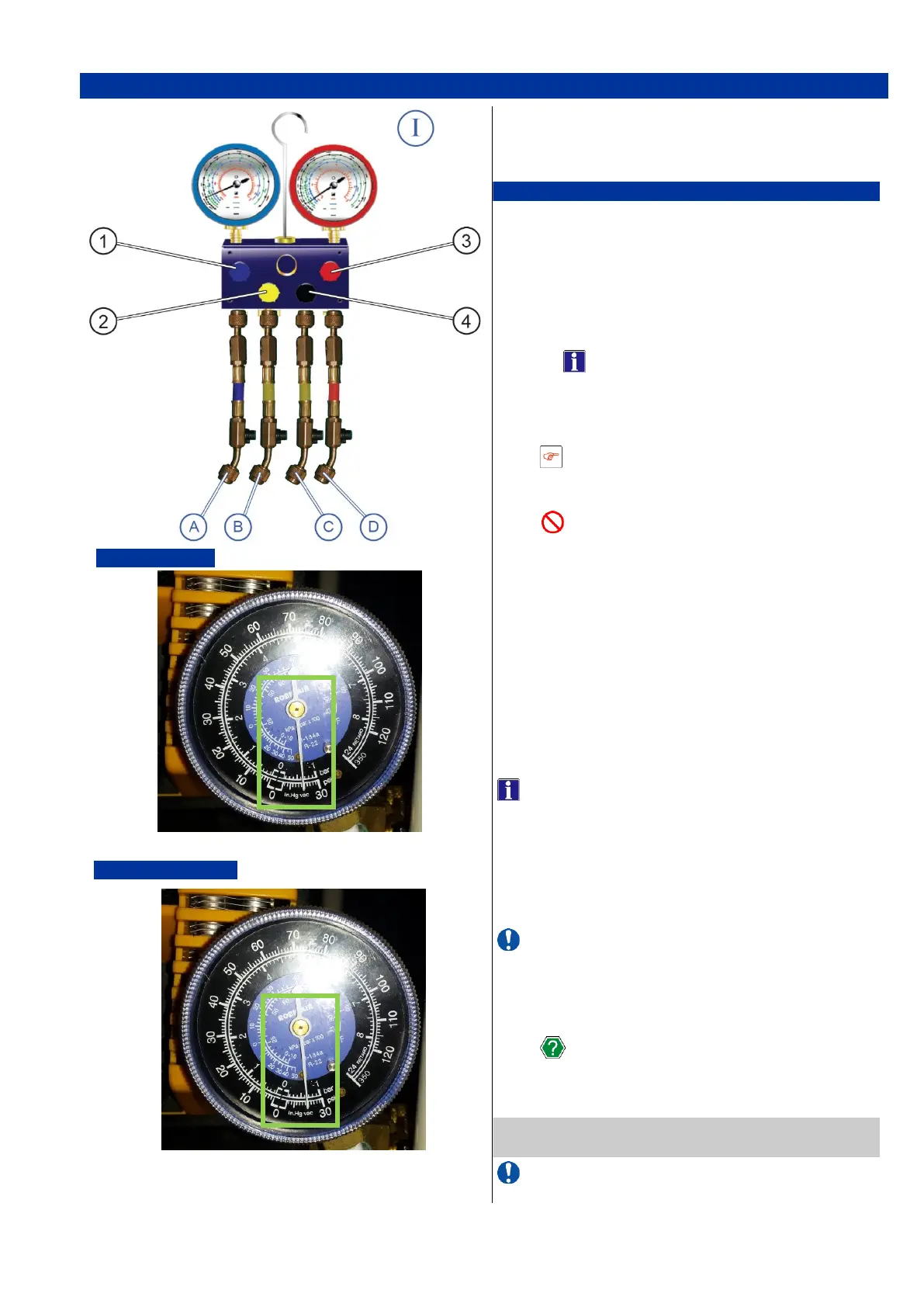

5. Check the pressure values indicated on the

two manifold gauges.

Wait until the needles from the 2 mani-

folds gauges indicate -0,67 bar (-20

inchHg).

Do not go to the next step before

reaching

-0,67bar (-20 inchHg) in order to pre-

vent flare up of residual refrigerant.

This specific effect has to be taken into

account especially in case of work in

height (fall risk).

The R-452A is recovered

6. Close hose (B) service valve.

7. Close the manifold gauges service valve (2).

8. Stop the recovery machine.

9. Wait for 15 minutes

After 15 minutes

If pressure has raised:

Repeat the Recovery procedure from step 1

If -0,67 bar (-20inchHg) maintained

Go to next step

10. Disconnect the recovery machine.

Dispose the R-452A recovery bottle accord-

ing local legislation.

End of recovery procedure

11. Purge with Nitrogen.

For more information about nitrogen

instruction:

Refer to the brazing instruction 98-60068-

00 available from CTE partner

The refrigerant circuit is ready for unbrazing

operation.

Perform unbrazing operation under nitrogen.

Loading...

Loading...