62-61753-21

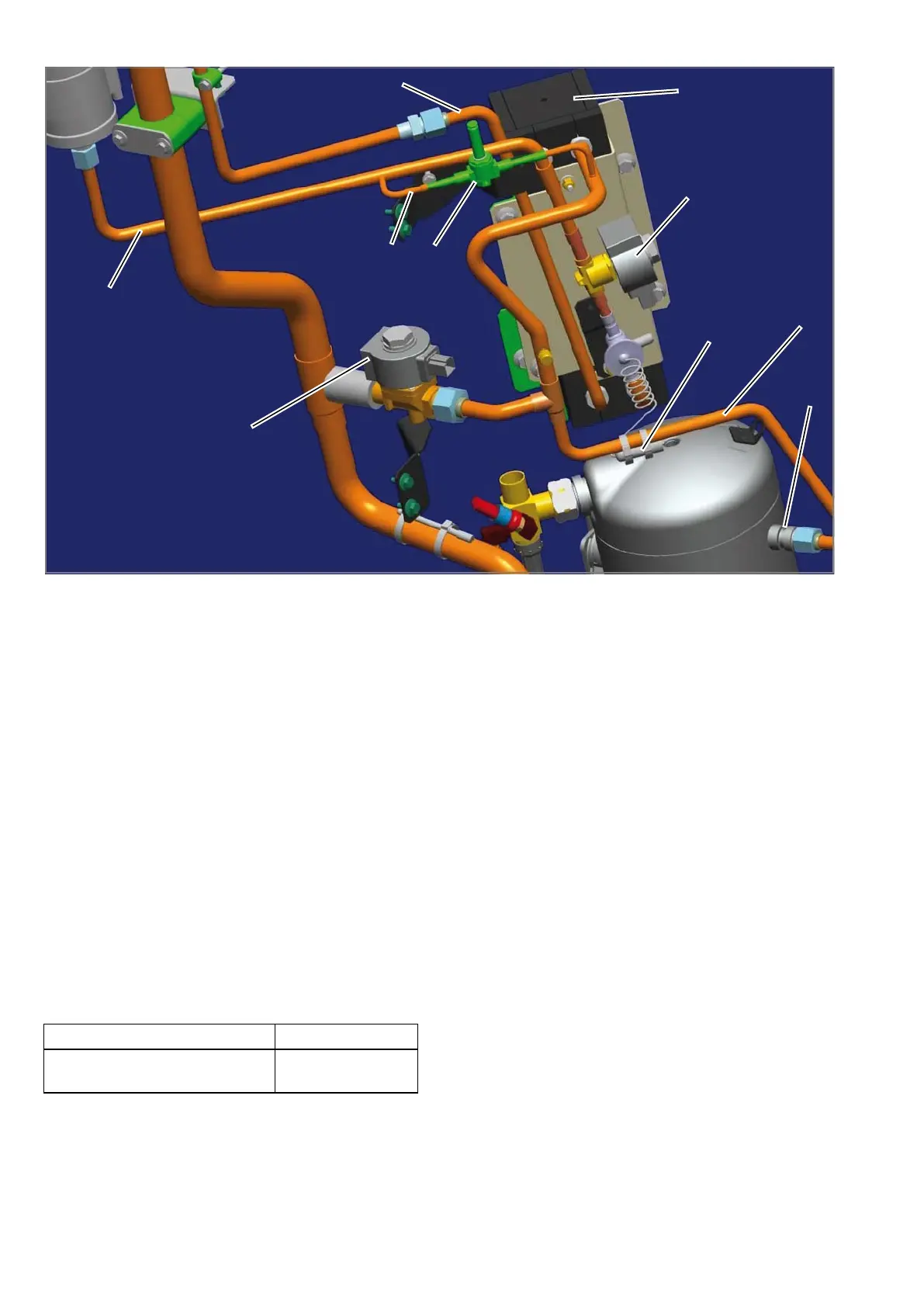

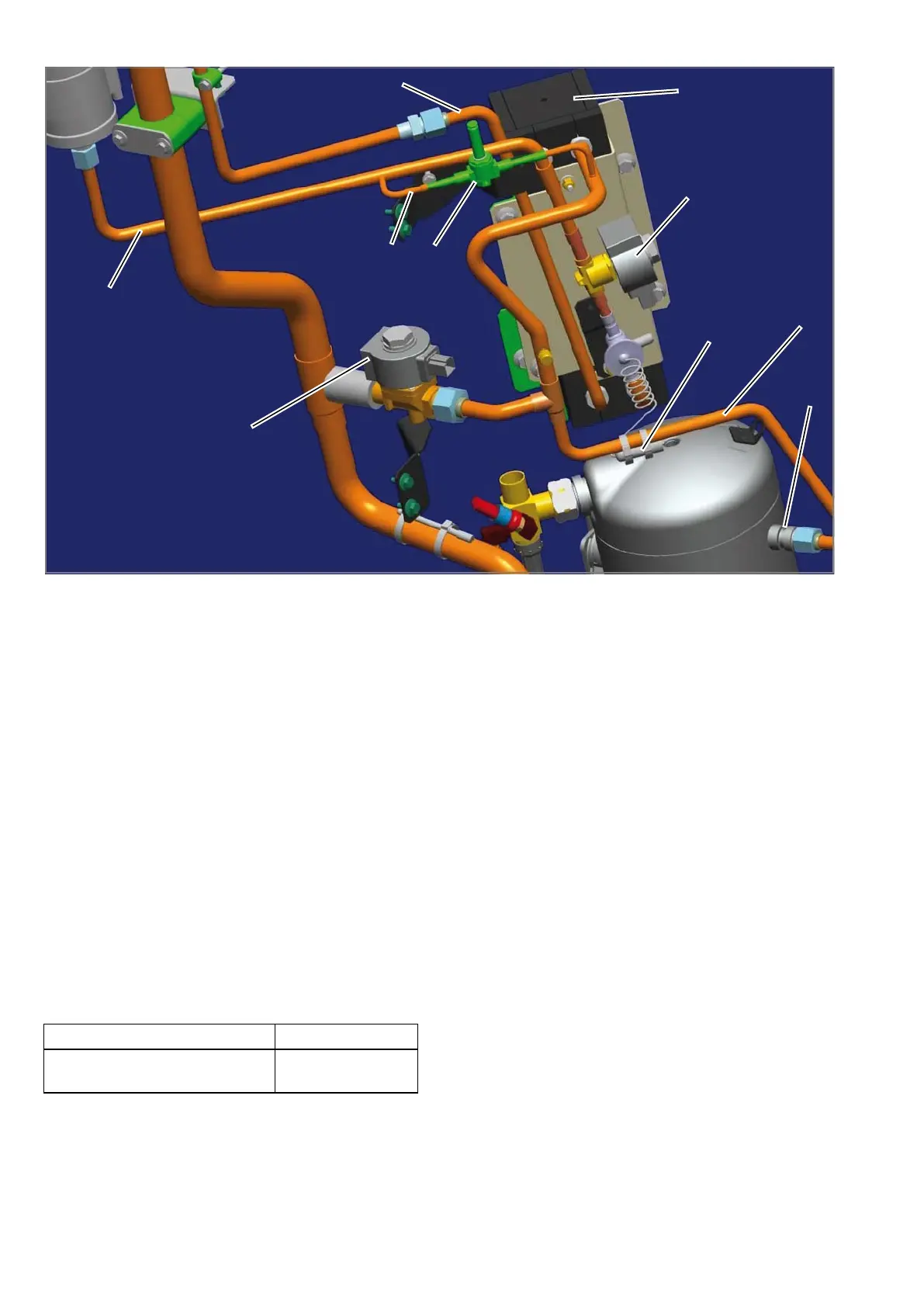

1. Liquid Inlet Line

2. Liquid Outlet Line

3. Liquid Injection Line

4. Economizer Heat Exchanger

5. Liquid Injection Solenoid Valve

6. Economizer Solenoid Valve

7. TXV bulb

8. Economizer Line

9. Compressor Economizer Connection

10. Unloader Solenoid Valve

Figure 8-13. Economizer Assembly

8.6.5 Filter Drier

To Check Filter Drier

Check for a restricted or plugged filter-drier by feeling

the liquid line inlet and outlet connections of the drier

cartridge. If the outlet side feels cooler than the inlet

side, then the filter-drier should be changed.

To Replace Filter Drier

a. Remove the refrigerant charge. (Refer to section

8.5.1).

b. Remove bracket, then replace drier.

c. Procure new O-rings. Lubricate the O-rings, back

side of sleeves and coupling nuts. Using a backup

wrench at each connection torque as follows

41 to 51 Nm

(30 to 38 ft-lbs.)

c. Leak check, evacuate the unit and charge in ac-

cordance with sections 8.5.2, 8.5.3 & 8.5.4.

8.6.6 Sight Glass Assembly

a. Remove the refrigerant charge. (Refer to section

8.5.1).

b. Remove the sight glass assembly and O-ring. Using

a new O-ring, install and torque to 50 to 60 Nm

(37-44 ft-lbs)

c. Leak check, evacuate the unit and charge in ac-

cordance with sections 8.5.2, 8.5.3 & 8.5.4.

8.6.7 Compressor Suction Modulation Valve

(CSMV)

The purpose of the SMV is to maintain the compressor

within its operating envelope and maximize unit capac-

ity and fuel economy.

At initial startup, the microprocessor will go through a

self test. When the test is complete, the Message-

Center will display "SMV CLOSING". Then the Mes-

sageCenter will display "SETTING SMV XX%" with

actual percentage depending on ambient temperature

and refrigerated compartment temperature. The unit

will then go through its normal start procedure.

Loading...

Loading...