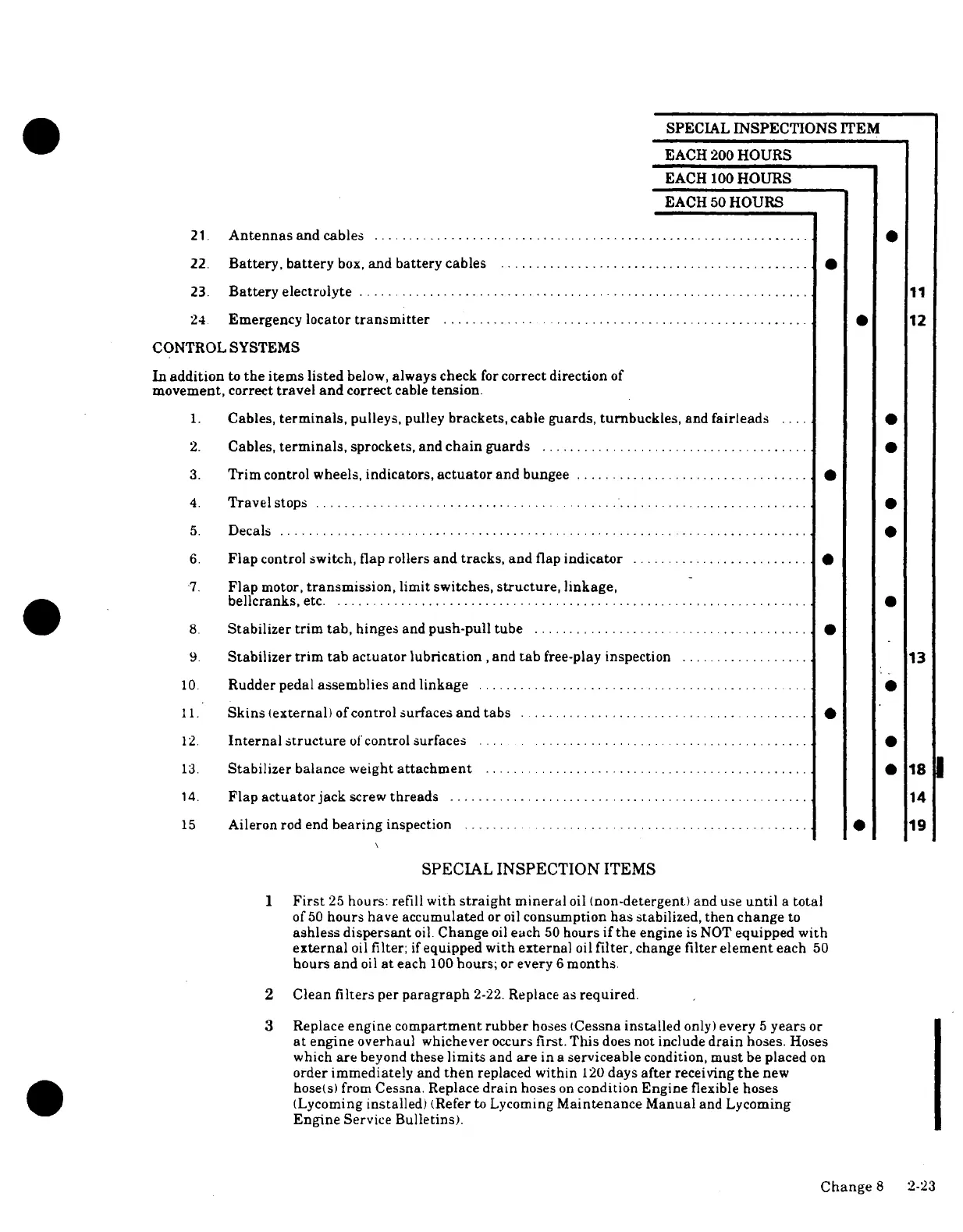

SPECIAL

INSPECTIONS

ITEM

EACH

200

HOURS

EACH

100

HOURS

EACH

50

HOURS

21.

A

ntennas

and

cables

..............................................................

22.

Battery,

battery

box,

and

battery

cables

............................................

·

23.

B

attery

electrolyte

................................................................

11

24

Emergency

locator

transmitter

.............

......................................

* 12

CONTROL

SYSTEMS

In

addition

to

the

items

listed

below,

always

check

for

correct

direction

of

movement,

correct

travel and

correct

cable

tension.

1.

Cables,

terminals,

pulleys,

pulley

brackets,

cable

guards,

turnbuckles,

and

fairleads

....

·

2.

Cables,

terminals,

sprockets,

and

chain

guards

......................................

3.

Trim

control wheels,

indicators,

actuator

and

bungee

................................. 0

4.

Travel

stops

..................................

...................

............

5.

Decals

..............................................................

6.

Flap

control

switch,

flap

rollers

and

tracks,

and

flap

indicator

.........................

7.

Flap

motor,

transmission,

limit switches,

structure,

linkage,

,*bellcranks,

etc.

........................................

...........................

·

8.

Stabilizer trim

tab,

hinges

and

push-pull

tube

......................................

9.

Stabilizer

trim

tab actuator

lubrication

,

and

tab

free-play

inspection

...................

13

10.

Rudder

pedal

assemblies

and

linkage

................ ..........................

.

11.

Skins

(external)

of

control

surfaces

and

tabs

. ......................................

12.

Internal

structure

ol

control

surfaces

.... .................

......................

13.

Stabilizer

balance

weight

attachment

.............................................

18

14.

Flap

actuator

jack

screw

threads

...................................................

14

15

Aileron

rod

end

bearing

inspection

.................................................

19

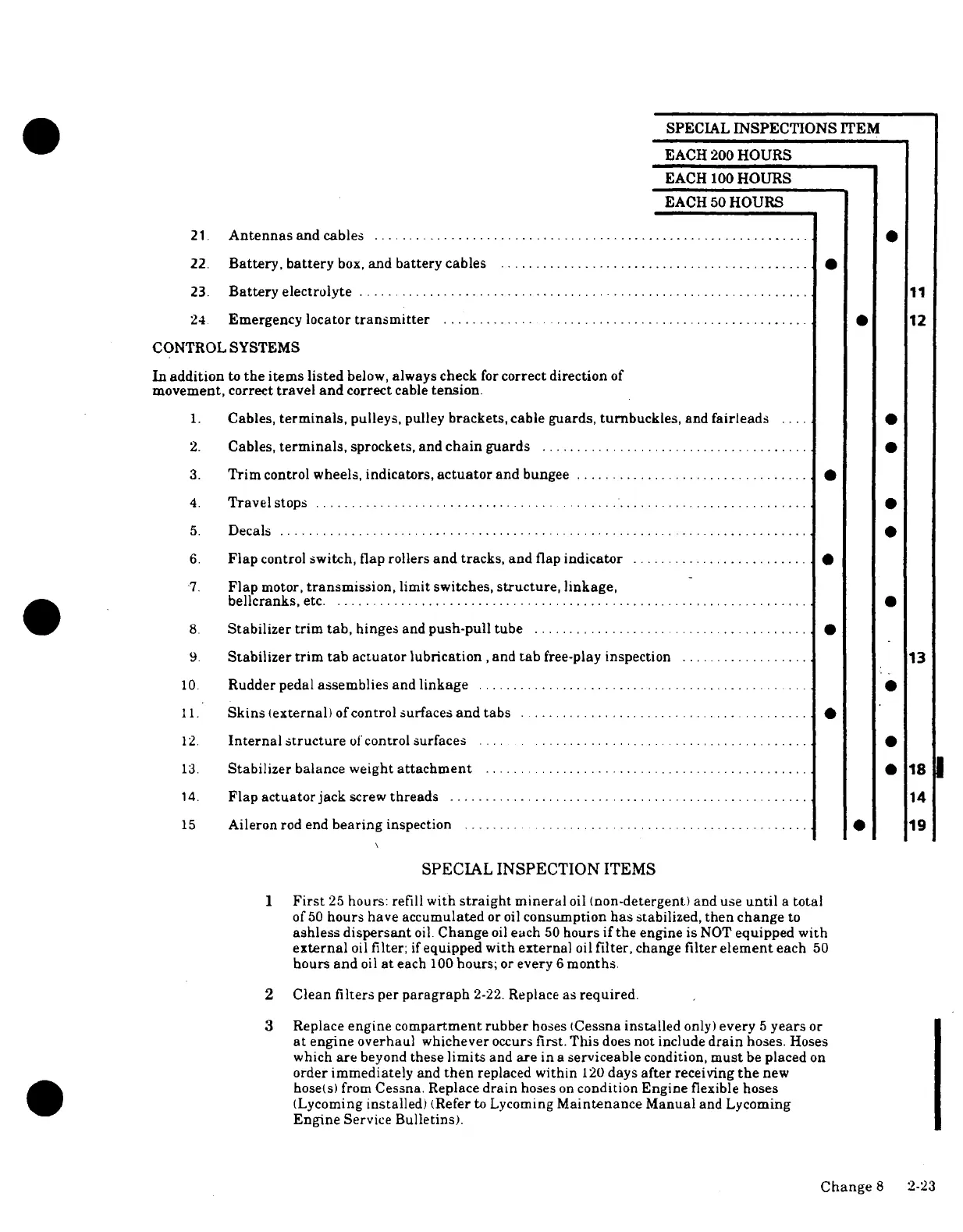

SPECIAL

INSPECTION

ITEMS

1

First

25

hours:

refill

with

straight

mineral

oil

(non-detergent)

and use

until

a

total

of

50

hours

have

accumulated

or

oil

consumption has

stabilized,

then change

to

ashless

dispersant

oil.

Change

oil

each

50

hours

if the

engine

is

NOT

equipped

with

external

oil

filter;

if

equipped

with

external

oil

filter,

change

filter

element

each

50

hours

and

oil

at

each

100

hours;

or

every

6

months.

2

Clean

filters

per

paragraph

2-22.

Replace

as

required.

3

Replace

engine

compartment

rubber

hoses

(Cessna

installed

only)

every

5

years

or

at

engine

overhaul

whichever

occurs

first.

This

does

not

include

drain

hoses.

Hoses

which

are

beyond

these

limits

and

are

in

a

serviceable

condition,

must

be

placed

on

order

immediately

and

then

replaced

within

120

days

after

receiving

the

new

hose(s) from

Cessna. Replace

drain

hoses

on

condition

Engine

flexible

hoses

(Lycoming

installed)

(Refer

to

Lycoming

Maintenance

Manual

and

Lycoming

Engine

Service

Bulletins).

Change

8

2-23

Loading...

Loading...