InteliLite

NT

– AMF20/25, SW version 1.2, ©ComAp – March 2008 61

IL-NT-AMF-Reference Guide1.2.pdf

Sensor Specification

Background of the sensor calibration

To correct measuring error of each analog input (pressure, temperature, level) calibrating constants

within 10 % of measure range should be set. Two calibrating constants are set in physical units - bar,

o

C, % .Calibration is made by adding the value of setpoint AIxCalibration directly to the calculated

value at analog input.

Hint

:

The calibration must be done at the operational point of the analog input (e.g. 80°C, 4.0Bar etc..)

Default sensor curves

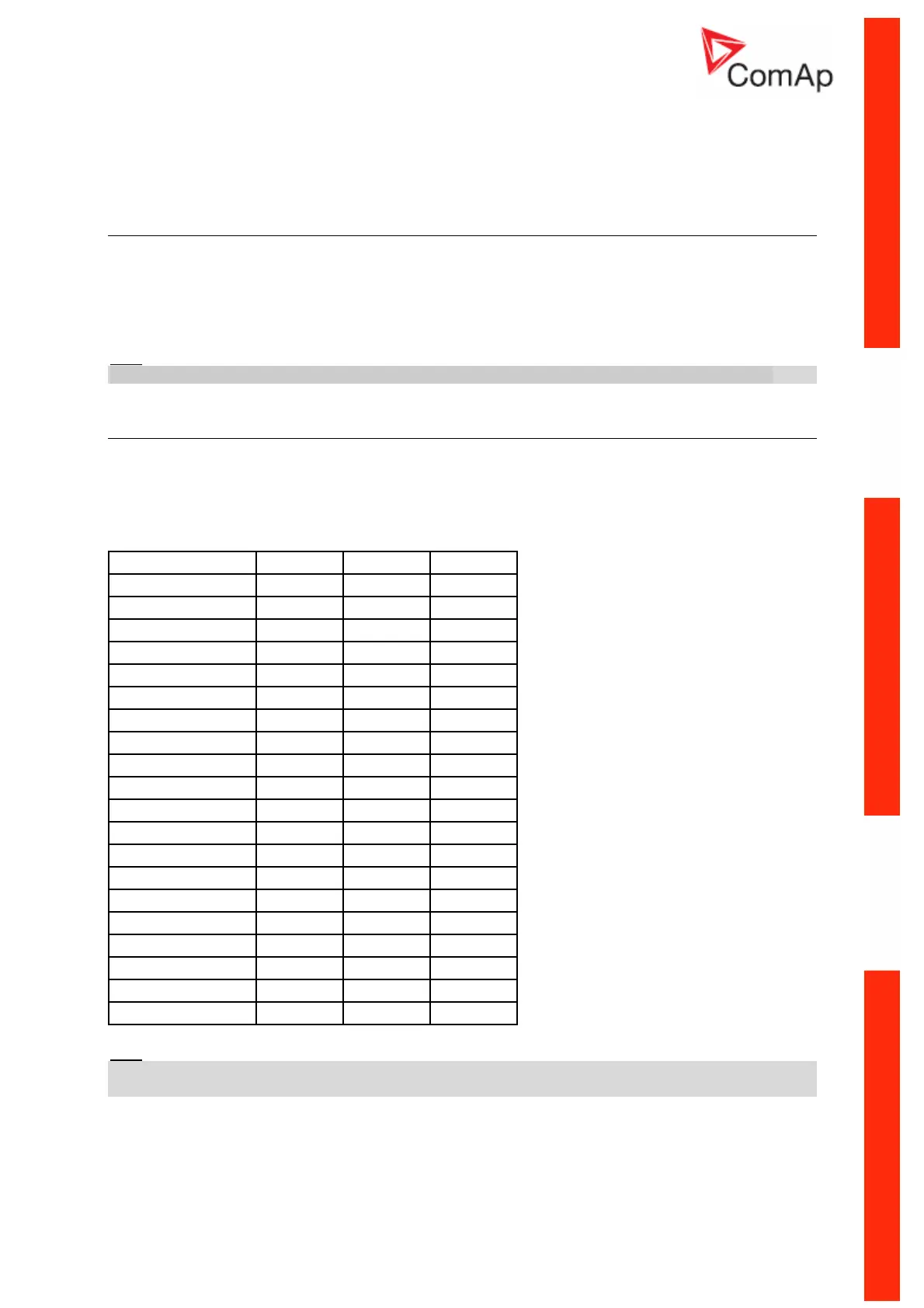

There are 20 resistive curves available. The following table provides information on

minimum/maximum values of respective sensors. Actual values especially of temperature curves may

differ. Meaning is to prolong curve to the lower temperature values, so the cold engine will not raise

alarm fail sensor.

Curve Min Value Max Value Unit

Datcon 5 Bar 0 5 Bar

Datcon 7 Bar 0 7 Bar

Datcon 10 Bar 0 10 Bar

Datcon 80 Psi 0 80 Psi

Datcon 100 Psi 0 100 Psi

Datcon 150 Psi 0 150 Psi

Datcon Low °C 25 150 °C

Datcon High °C 25 160 °C

Datcon Low °F 80 300 °F

Datcon High °F 80 320 °F

Datcon Fuel % 0 100 %

VDO 5 Bar 0 5 Bar

VDO 10 Bar 0 10 Bar

VDO 72 Psi 0 72 Psi

VDO 145 Psi 0 145 Psi

VDO 40-120 °C 40 120 °C

VDO 50-150 °C 50 150 °C

VDO 100-250 °F 100 250 °F

VDO 120-300°F 120 300 °F

VDO Fuel % 0 100 %

Hint:

When measured value is 6% out of range the Sensor fail FLS is detected. You can find detail

information on sensores in LiteEditu Reference Guide.

Loading...

Loading...