CAUTION: Wear appropriate safety eye wear when using compressed air.

To replace the isolation valve seals:

CAUTION: Take care to keep all parts clean while assembling.

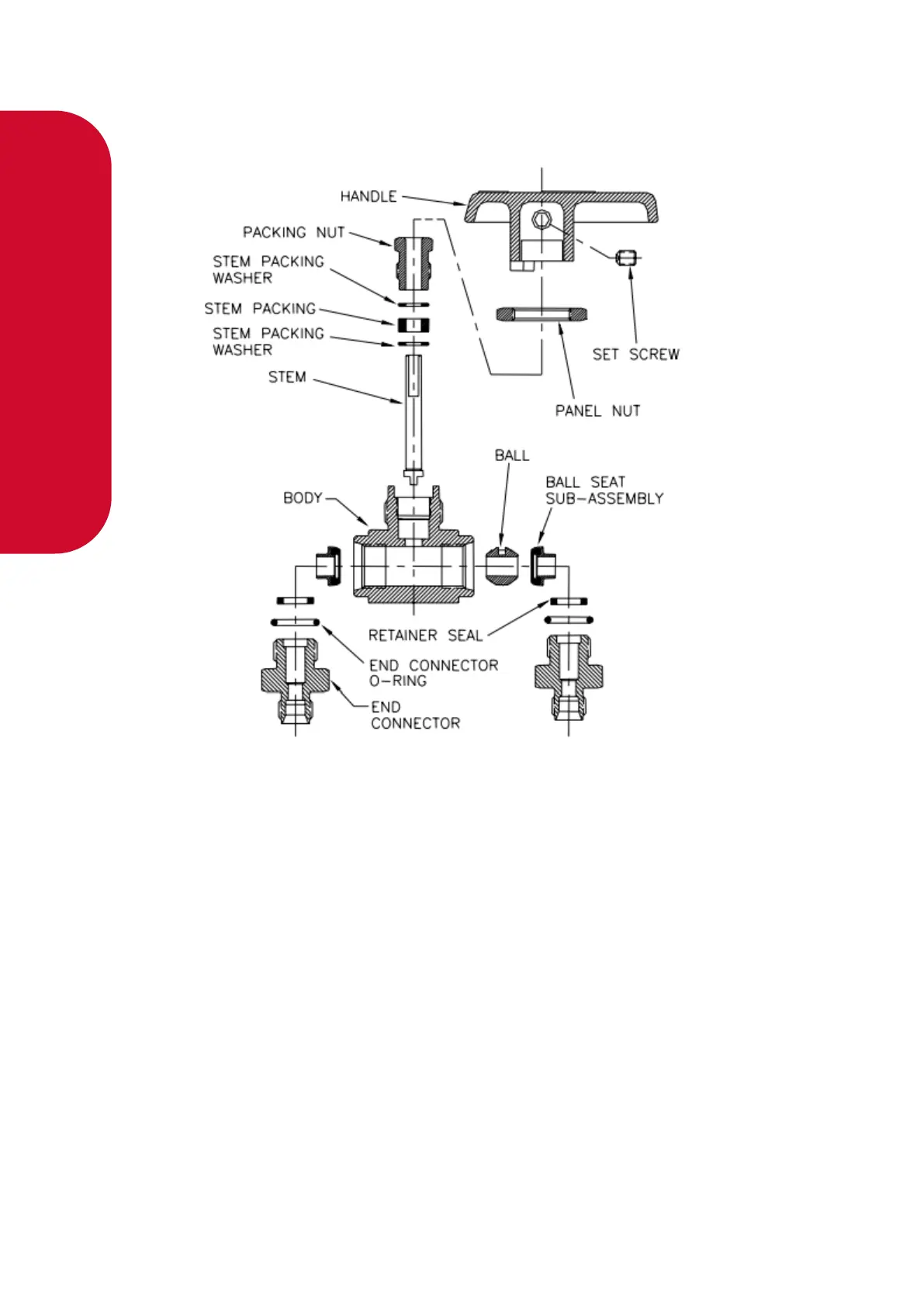

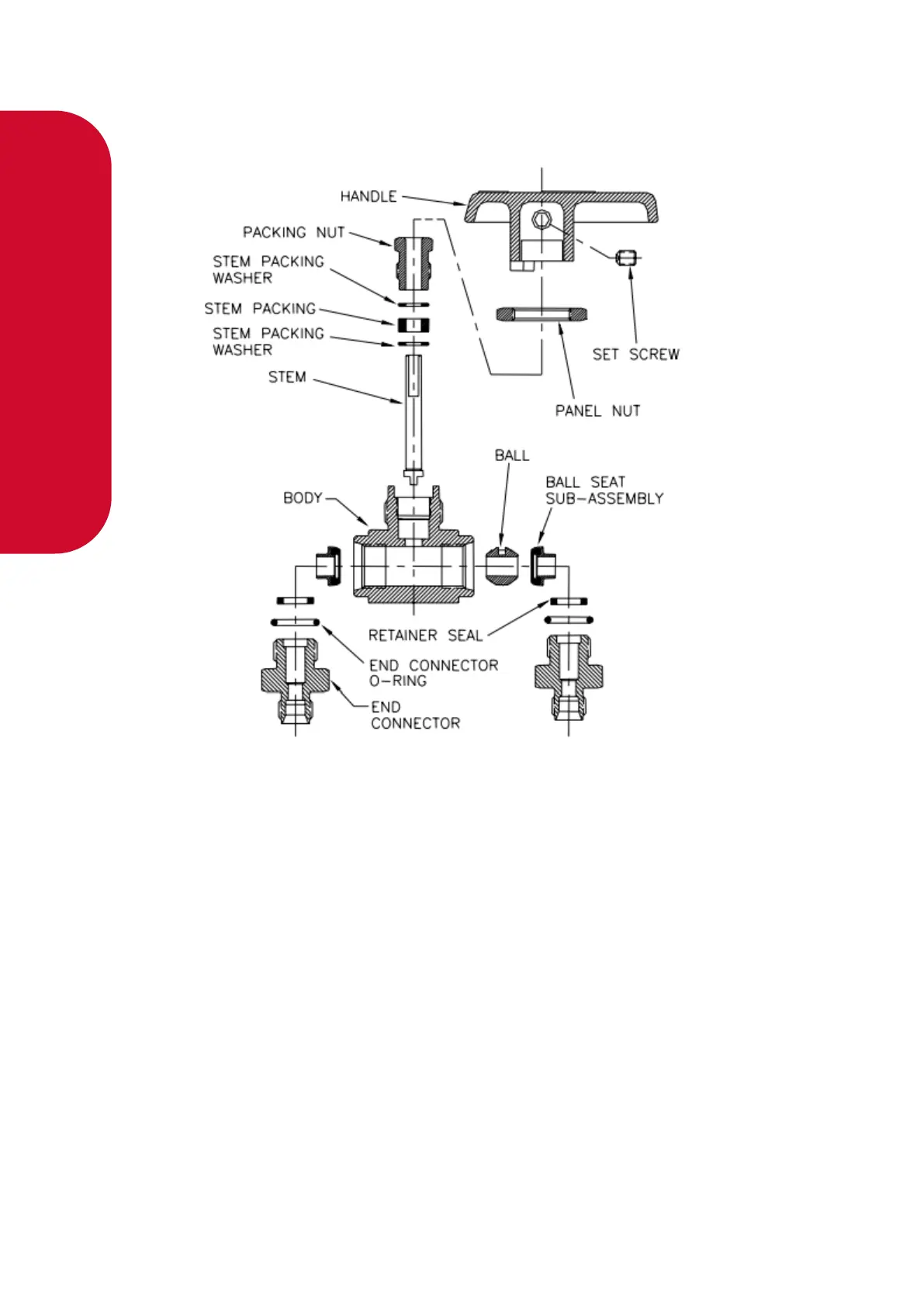

- Apply a light coating of approved grease to the ball then replace the ball

and ball seat sub-assemblies, making sure the slot in the ball is at the

top.

- Making sure the retainer seal and end connector O ring are in place,

screw in the end connectors. Do not tighten yet.

- Locate the stem in the ball slot then replace the stem washers, stem

packing and packing nut.

- Open and close the valve a few times to seat the ball valve before

tightening the end connectors and packing nut.

- Reattach the valve to the cabinet and reconnect the pipework.

- Reapply gas to the valve and check for leaks.

Loading...

Loading...