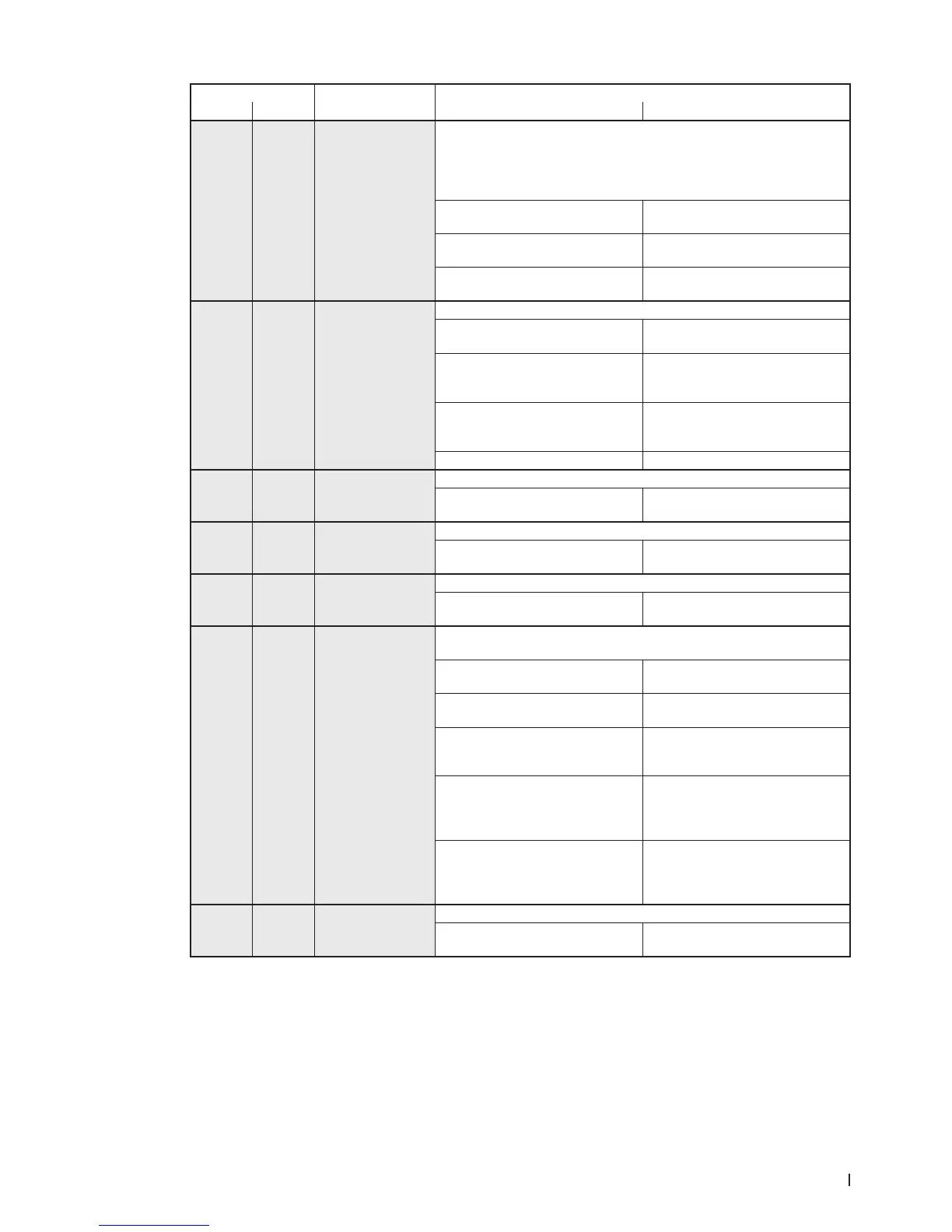

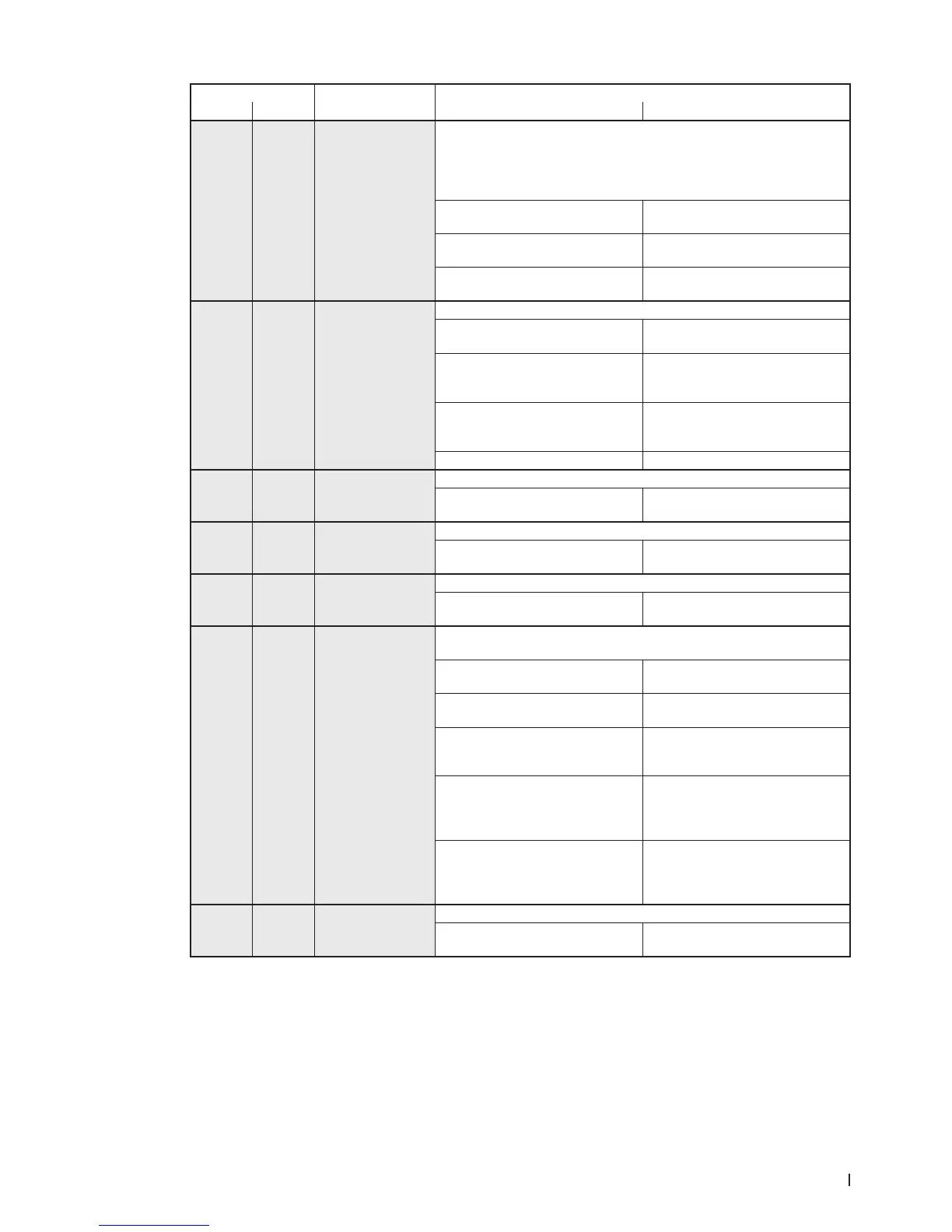

71Fault elimination

Code Message Information

Warning Fault Possible causes Remedy

W71 ––– Low conductivity If the cylinder has had reduced operating capacity and excessive high water sen-

sor activations before the break-in period of the cylinder has expired the system

will generate a low conductivity warning instead of a spent cylinder notication.

This will allow decrementation of the high water sensor counter for a period of

operating time before generating a spent cylinder code.

Wrong cylinder type installed Install steam cylinder for low conduc-

tivity.

Cylinder receptacle leaking. Check/seal/replace cylinder recep-

tacle.

Supply water has too low water con-

ductivity.

Connect water supply with water

conductivity in admissible range.

––– E84 Driver fault No communication between the controller and the driver board

Driver board defective. Let have the driver board be replaced

by an electrician.

Driver board ID wrong. Check rotary switch SW1 on the driver

board and set correctly (0 for cylinder

A, 1 for cylinder B).

Communication cable between the

driver board and the control board

not connected properly

Make sure the RS485 cable is con-

nected to RS4851 on the driver board

and J12 on the control board.

Wrong version of driver board. Contact your Condair representative.

W125 ––– Capacity Timer The capacity limitation is currently controlled via Capacity Timer function.

The Capacity Timer is active and has

over ridden the normal operation.

No action is required.

W126 ––– Setpoint Timer The setpoint is currently controlled via the Setpoint Timer function.

The Setpoint Timer is active and has

over ridden the normal operation.

No action is required.

––– E128 Current Sensor Current sensor not able to be calibrated on system start-up.

Current sensor not able to be calibrated

on system start-up

Contact your Condair representative.

––– E130 Current Circuit Current monitoring circuit has detected that current has exceeded maximum

allowable current.

Current coils disconnected or not func-

tioning.

Check wiring between current coils and

driver board.

One of the phases is disconnected. Check fuses, wiring to humidier, and

supply voltage is present on all phases.

Electrode plugs on cylinder not con-

nected.

Check that all Electrode plugs are

properly connected and that wiring is

secure to contactor.

Inlet valve stuck open. Check that the inlet valve is closed,

after full output is reached. If not,

check/Replace inlet valve if neces-

sary.

Drain pump is blocked preventing drain

to dilute cylinder water.

Check that water drains correctly

from cylinder when manual drain is

activated. If not, check/Replace drain

pump if necessary.

––– E131 Missing Coil One of the current coils used for monitoring the humidiers current is not detected.

Current coil is not connected. Check/connect wires between current

coils and driver board.

Loading...

Loading...