36 Maintenance

If the corresponding maintenance counter has elapsed, the yellow LED above the unit switch and on

units with optional RM Display additional the yellow warning triangle in the upper left corner of the dis-

play indicate that a maintenance must be carried out. In the fault list "Warning 29" is shown if the unit

maintenance must be carried out or "Warning 165" if the optional lter cartridge must be replaced. The

steam humidier Condair RM continues normal operation.

Note: If a maintenance is due, the buzzer sounds at any time the unit is switched on and in regular intervals

during operation. The buzzer sound can be deactivated in the "Engineering" menu of the RM Display.

Carry out the corresponding maintenance work, then reset the corresponding maintenance counter

(see chapter 7.8).

Note: If during servicing a low or an increased calcication of the steam tank is determined, the main-

tenance interval time can increased (by reducing the carbonate hardness) or decreased (by increasing

the carbonate hardness).

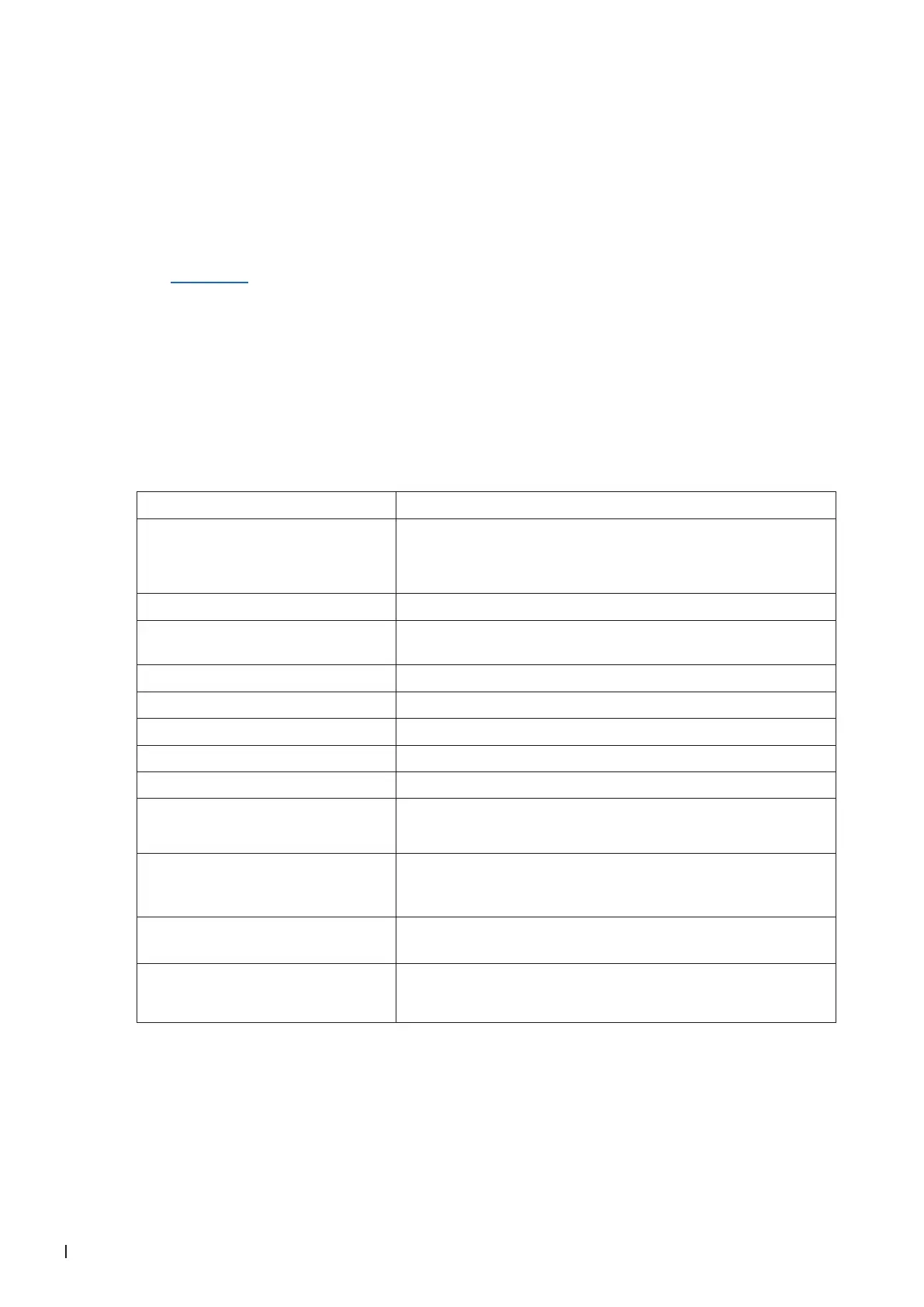

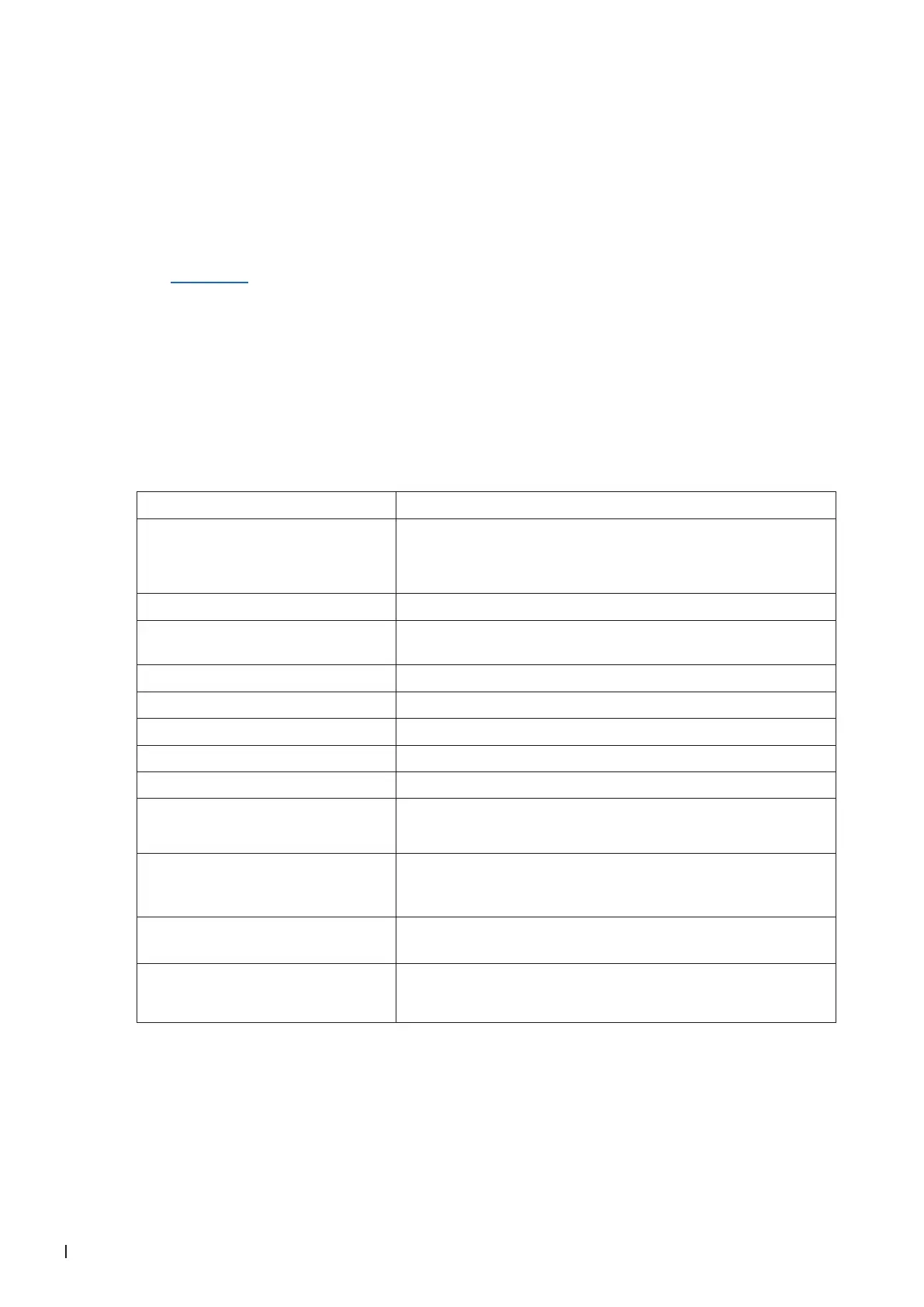

7.3 Maintenance list

Adjacent you can nd an overview of the maintenance work to be carried out at the unit maintenance.

Components Work to be done

Steam tank Remove, disassemble and clean, replace defective components if necessary.

Note: When operating the Condair RM with the optional lter cartridge slight

lime traces in the steam tank are normal. However, these slight lime traces

must not be removed.

Steam tank receptacle Inspect, clean if necessary.

Drain pump Remove, disassemble and clean, replace if necessary.

Inlet valve Remove and clean lter insert, replace if necessary.

Filling cup Inspect, clean if necessary.

Level unit Inspect, clean if necessary.

Drain Inspect, clean if necessary.

Drain pipe and siphon Inspect, clean if necessary (decalcify and rinse out).

Steam installation Inspect steam and condensate hoses for cracks and ensure that they are cor-

rectly attached, replace defective hoses.

Water installation Inspect water hoses in the unit for cracks and to see that they are correctly

attached, replace defective hoses.

Check supply pipe is tight, tighten it if necessary. Clean water lter, if available.

Electrical installation Have all cables in the unit checked by an electrician that they are correctly xed

and that the insulation is not damaged

Heating elements Check the resistance of the heating elements.

Note: a heating element is defective and must be replaced, if the resistance

value measured is >20 Ω.

Loading...

Loading...