SiE33-102 Installation

General Information 25

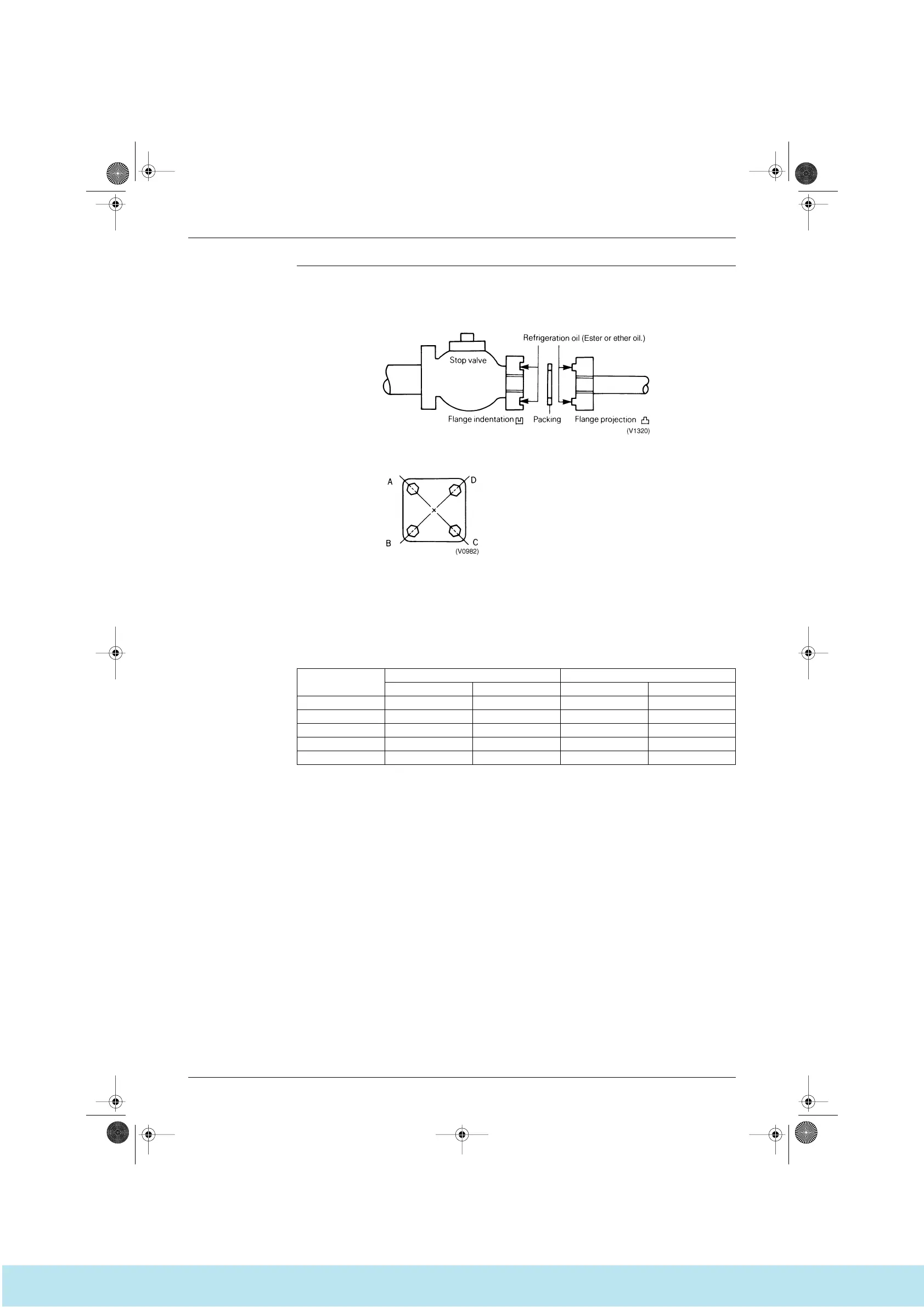

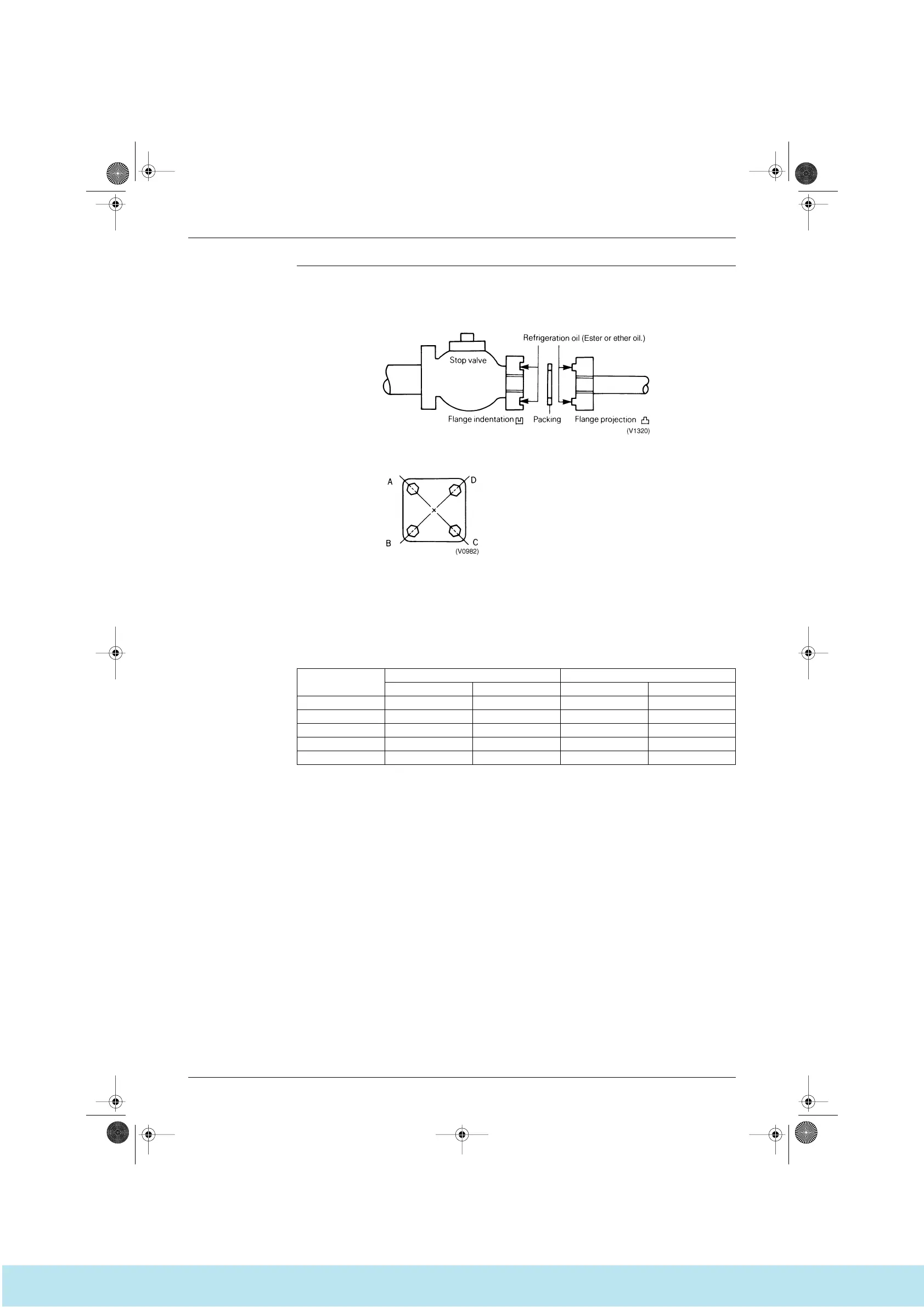

Flange Connection a) The flange sheet surface should be clean and undamaged. (Clean any dirt away with a cloth and check

that there has been no damage.)

b) Coat the flange sheet surface with refrigeration oil (Ester or ether oil) and then insert the packing. (Do

not use SUNISO oil.)

c) Tighten the bolts in opposite corners first to ensure that the connection is true.

Important points

1. Only clean refrigeration/oil should be used to coat the flange. (i.e. free from dirt or water)

2. The correct amount of torque should be applied when tightening the flange bolts.

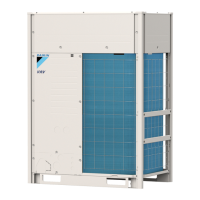

Standard torques for tightening screws and bolts

ISO hexagonal bolt

[Example]

Order:A→C→B→D The bolts should be tightened little by

little in the above order such that the

same degree of torque is applied

evenly to each corner.

Class 5.8(5T) 10.9(10T)

Size kgf-cm ±15% N-m ±15% kgf-cm ±15% N-m ±15%

M8 125 1230 302 2960

M10 257 2520 620 6080

M12 436 4280 1,050 10,300

M16 1,030 10,100 2,480 24,300

M20 2,050 20,100 4,950 48,500

Si33-102.book Page 25 Tuesday, June 26, 2001 3:18 PM

Все каталоги и инструкции здесь: http://splitoff.ru/tehn-doc.html

Loading...

Loading...