Requirements related to the Ex-e motor

•

Ensure that the Ex-e motor is approved for

operation in hazardous zones (ATEX zone 1/21,

ATEX zone 2/22) with drives. The motor must be

certied for the specic hazardous zone.

•

Install the Ex-e motor in zone 1/21 or 2/22 of the

hazardous zone, according to motor approval.

NOTICE!

Install the drive outside the hazardous zone.

•

Ensure that the Ex-e motor is equipped with an

ATEX-approved motor overload protection device.

This device monitors the temperature in the

motor windings. If there is a critical temperature

level or a malfunction, the device switches o the

motor.

-

The VLT

®

PTC Thermistor Card MCB 112

option provides ATEX-approved

monitoring of motor temperature. It is a

prerequisite that the drive is equipped

with 3–6 PTC thermistors in series

according to DIN 44081 or 44082.

- Alternatively, an external ATEX-approved

PTC protection device can be used.

•

Sine-wave

lter is required when

- Long cables (voltage peaks) or increased

mains voltage produce voltages

exceeding the maximum allowable

voltage at motor terminals.

- Minimum switching frequency of the

drive does not meet the requirement

stated by the motor manufacturer. The

minimum switching frequency of the

drive is shown as the default value in

parameter 14-01 Switching Frequency.

Compatibility of motor and drive

For motors certied according to EN-60079-7, a data list

including limits and rules is supplied by the motor

manufacturer as a data sheet, or on the motor nameplate.

During planning, installation, commissioning, operation,

and service, follow the limits and rules supplied by the

manufacturer for:

•

Minimum switching frequency.

•

Maximum current.

•

Minimum motor frequency.

•

Maximum motor frequency.

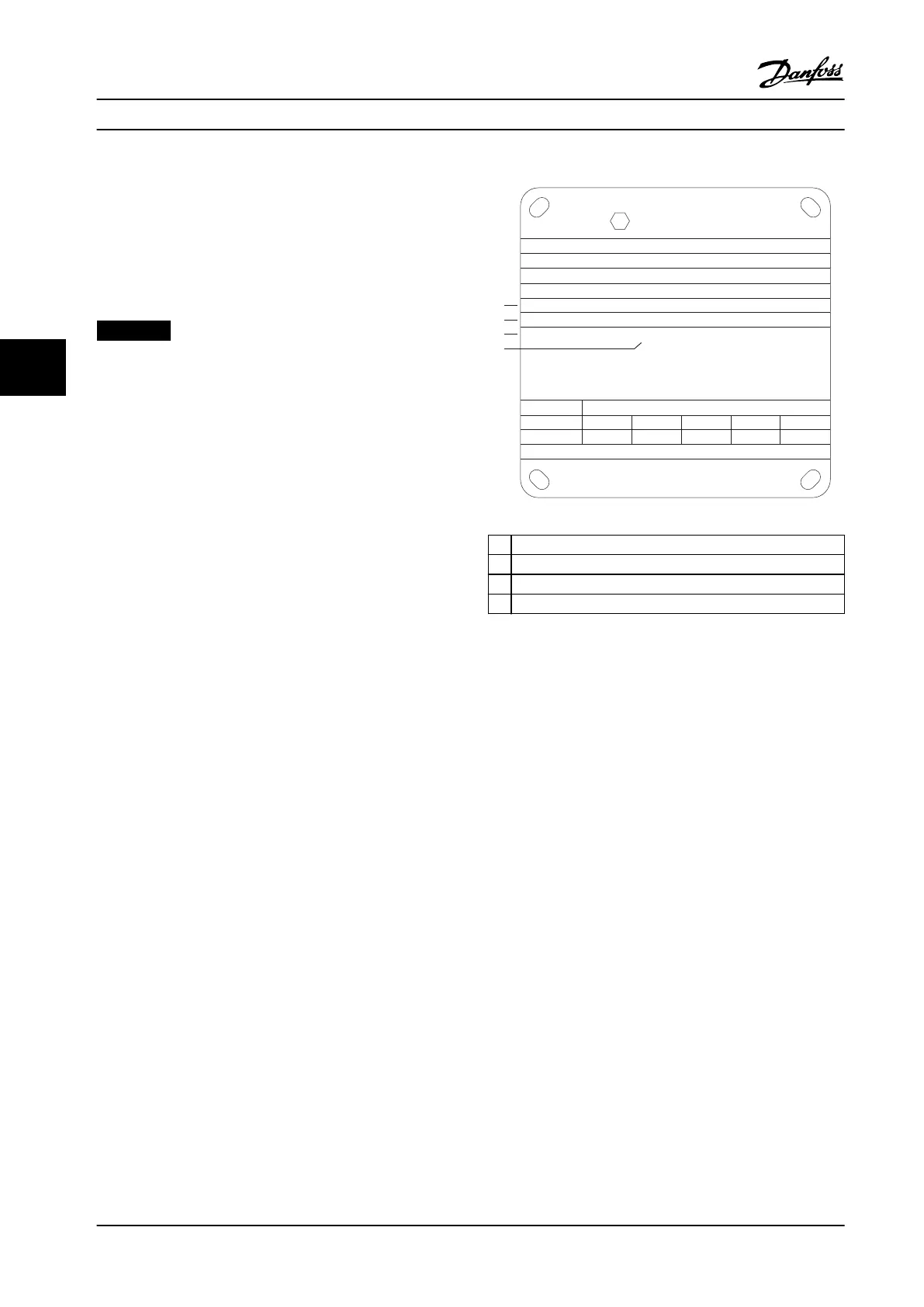

Figure 5.2 shows where the requirements are indicated on

the motor nameplate.

130BD888.10

CONVERTER SUPPLY

VALID FOR 380 - 415V FWP 50Hz

3 ~ Motor

MIN. SWITCHING FREQ. FOR PWM CONV. 3kHz

l = 1.5XI

M,N

tOL = 10s tCOOL = 10min

MIN. FREQ. 5Hz MAX. FREQ. 85 Hz

PWM-CONTROL

f [Hz]

Ix/I

M,N

PTC °C DIN 44081/-82

Manufacture xx

EN 60079-0

EN 60079-7

СЄ 1180 Ex-e ll T3

5 15 25 50 85

0.4 0.8 1.0 1.0 0.95

1

xЗ

2

3

4

1 Minimum switching frequency

2 Maximum current

3 Minimum motor frequency

4 Maximum motor frequency

Figure 5.2 Motor Nameplate showing Drive Requirements

When matching drive and motor, Danfoss species the

following extra requirements to ensure adequate motor

thermal protection:

•

Do not exceed the maximum allowed ratio

between drive size and motor size. The typical

value is I

VLT, n

≤2xI

m,n

•

Consider all voltage drops from drive to motor. If

the motor runs with lower voltage than listed in

the U/f characteristics, current can increase,

triggering an alarm.

For further information, see the application example in

chapter 12 Application Examples.

Product Features

VLT

®

AQUA Drive FC 202

22 Danfoss A/S © 01/2018 All rights reserved. MG22B222

55

Loading...

Loading...