6.2.8 Efficiency

Efficiency of the frequency converter

The load on the frequency converter has little effect on its

efficiency.

This also means that the frequency converter efficiency

does not change when other U/f characteristics are chosen.

However, the U/f characteristics do influence the efficiency

of the motor.

The efficiency declines a little when the switching

frequency is set to a value above 5 kHz. The efficiency is

also slightly reduced when the motor cable is longer than

30 m.

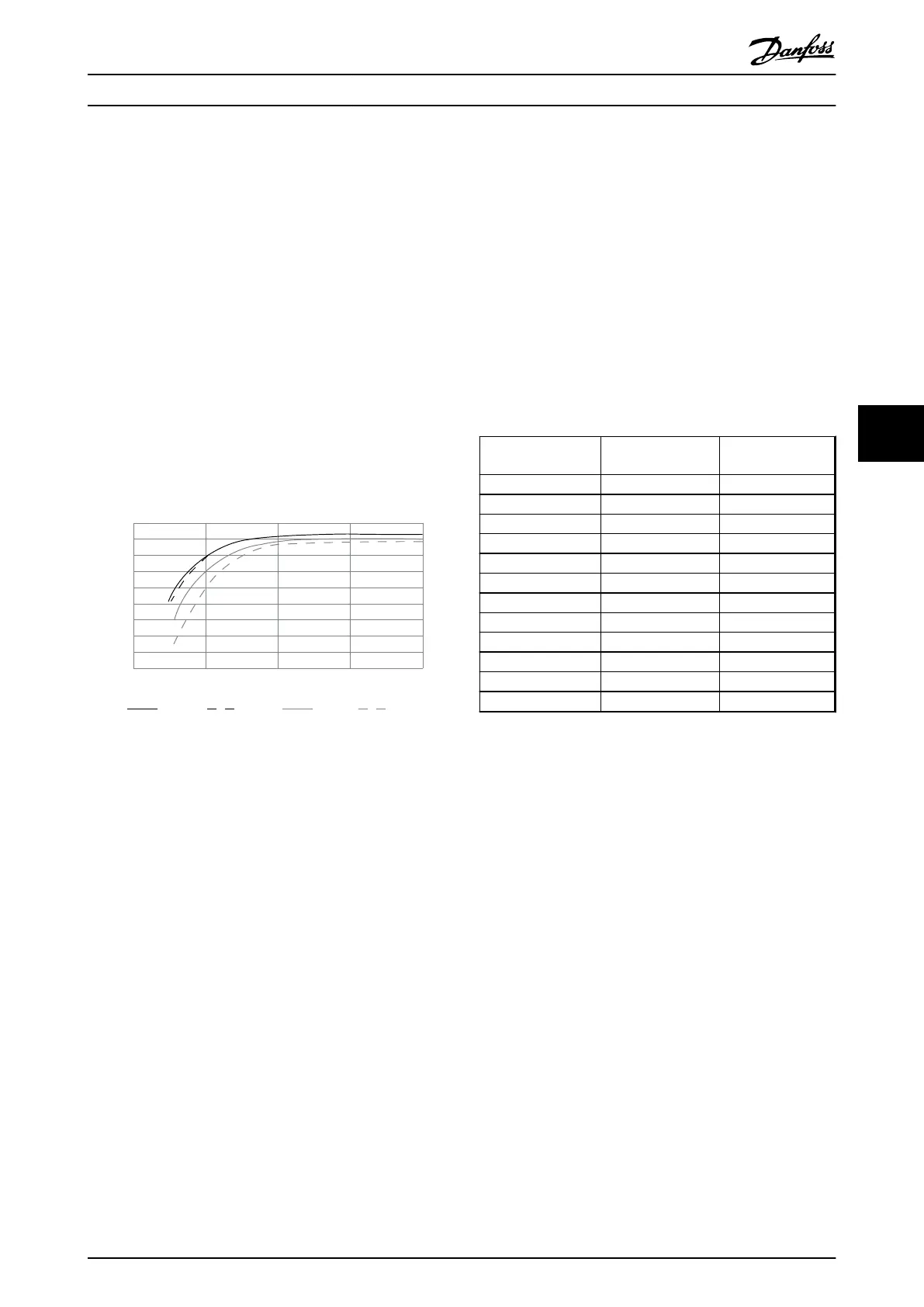

Efficiency calculation

Calculate the efficiency of the frequency converter at

different loads based on Illustration 6.35. Multiply the factor

in this graph with the specific efficiency factor listed in

chapter 6.2 General Specifications.

1.0

0.99

0.98

0.97

0.96

0.95

0.93

0.92

0% 50% 100% 200%

0.94

Relative Eciency

130BB252.11

1.01

150%

% Speed

100% load 75% load 50% load 25% load

Illustration 6.35 Typical Efficiency Curves

Example: Assume a 55 kW, 380-480 V AC frequency

converter with 25% load at 50% speed. The graph is

showing 0.97 rated efficiency for a 55 kW frequency

converter is 0.98. The actual efficiency is then: 0.97 x

0.98=0.95.

Motor efficiency

The efficiency of a motor connected to the frequency

converter depends on magnetising level. The efficiency of

the motor depends on the type of motor.

•

In the range of 75-100% of the rated torque, the

efficiency of the motor is practically constant,

both when it is controlled by the frequency

converter and when it runs directly on mains.

•

The influence from the U/f characteristic on small

motors is marginal. However, in motors from 11

kW and up, the efficiency advantage is significant.

•

The switching frequency does not affect the

efficiency of small motors. Motors from 11 kW

and up have their efficiency improved 1-2%. This

is because the sine shape of the motor current is

almost perfect at high switching frequency.

System efficiency

To calculate the system efficiency, the efficiency of the

frequency converter is multiplied by the efficiency of the

motor.

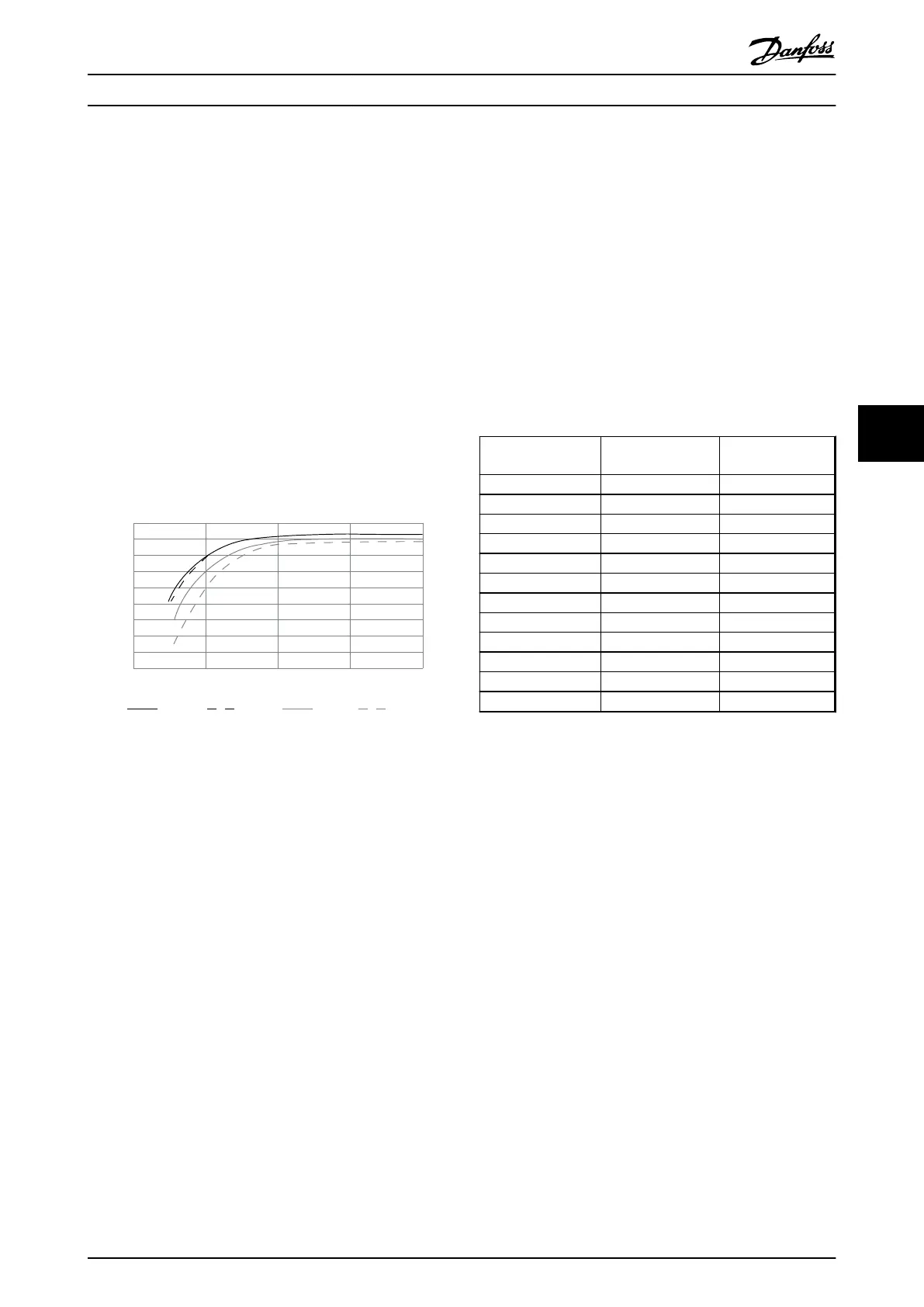

6.2.9 Acoustic Noise

Acoustic noise from the frequency converter comes from 3

sources

•

DC-link (intermediate circuit) coils

•

RFI filter choke

•

Internal fans

See Table 6.38 for acoustic noise ratings.

Enclosure type

50% fan speed

[dBA]

Full fan speed

[dBA]

A1 51 60

A2 51 60

A3 51 60

A4 51 60

A5 54 63

B1 61 67

B2 58 70

B4 52 62

C1 52 62

C2 55 65

C4 56 71

D3h 58 71

Table 6.38 Acoustic Noise Ratings

Values are measured 1 m from the unit.

Product Specifications

VLT

®

AutomationDrive FC 301/FC 302 Design Guide, 0.25-75 kW

MG33BF02 - Rev. 2013-12-20 81

6 6

Loading...

Loading...