D-100 MK2 User Manual Firmware V-6.3

K96D01-EN - 65 -

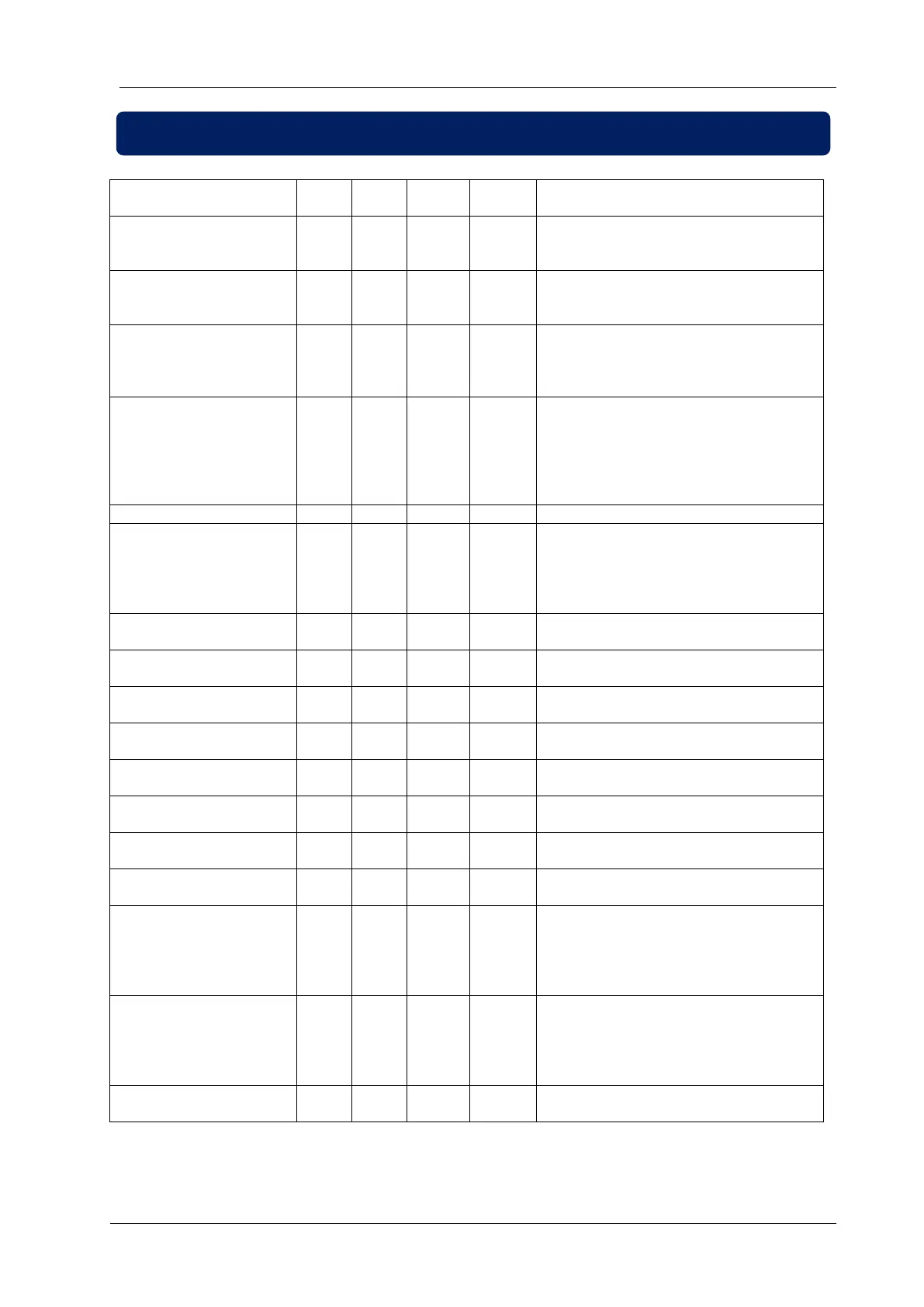

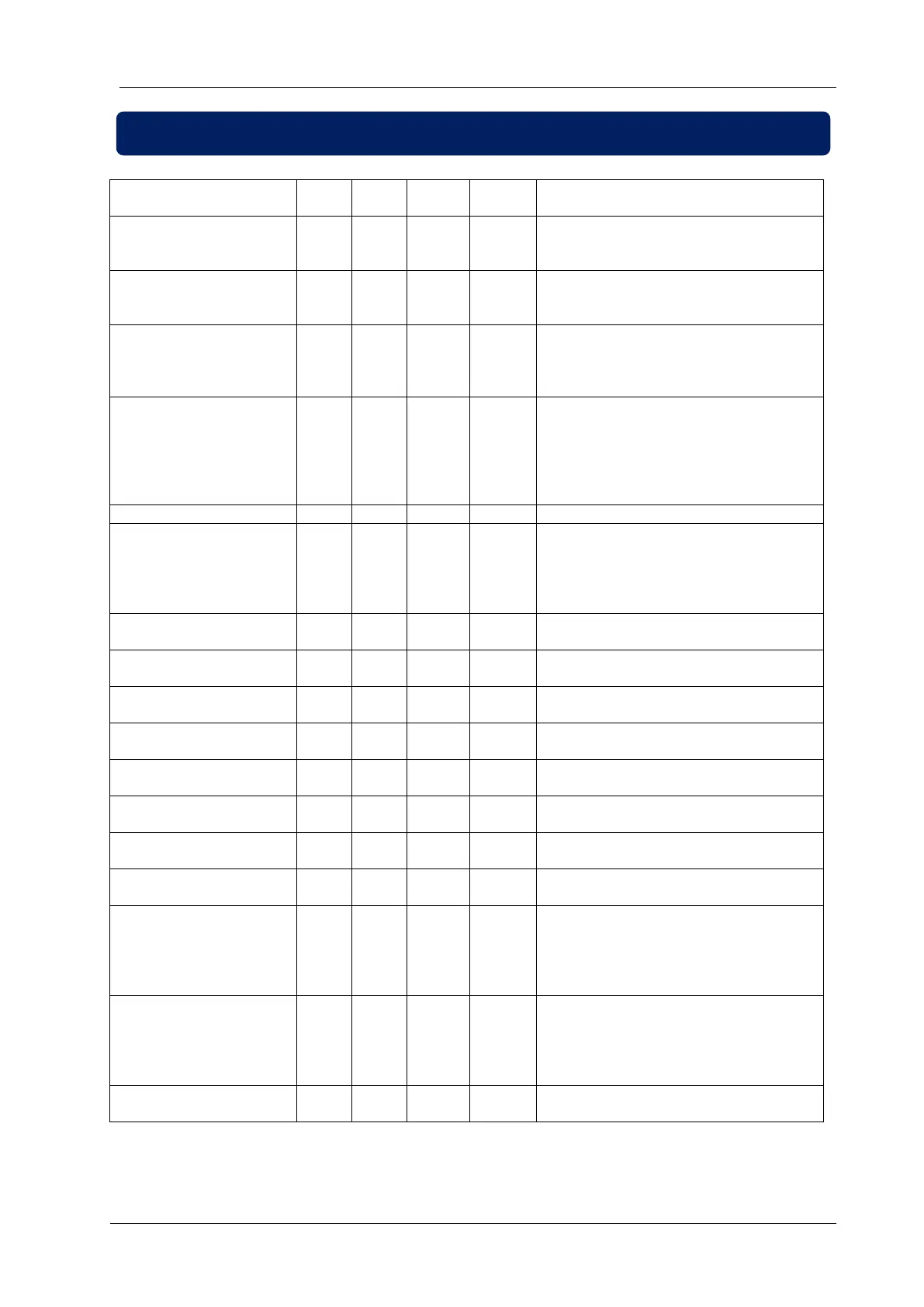

This parameter is used to set LCD

contrast. Adjust for the best viewing

angle.

This parameter defines the delay after

the engine runs and before the fault

monitoring is enabled.

This is the period during which the

ALARM relay is active. If the period is

set to 0, this will mean that the period is

unlimited.

004-Emergency Backup

Operation

0: In RUN mode, the load will not be

transferred to the genset even if the

mains fails.

1: In RUN mode, the load will be

transferred to the genset if the mains

fails.

0: exercise once per week

1: exercise once per month

The exact exerciser day and time is

adjusted within the EXERCISE

SCHEDULE section.

008-Delayed Simulate

Mains

0: delayed simulate mains disabled

1: delayed simulate mains enabled

010-GPRS Connection

Enable

011-Rainbow Scada

Refresh Rate

The unit will update the distant

monitoring terminal with this rate.

This is the port number of the first

monitoring terminal address.

This is the port number of the second

monitoring terminal address.

This is the modbus controller identity

used in Modbus communication.

015-Oil Pressure Switch

Priority

0: crank cut is performed through oil

pressure switch and oil pressure sender

reading

1: crank cut is performed only through

oil pressure switch

016-Flashing Relay ON

Timer

Delayed Simulate Mains Operation:

max genset running time after Simulate

Mains signal disappears.

Dual Genset Systems: flashing relay

ON state duration timer.

017-Flashing Relay OFF

Timer

Dual Genset Systems: flashing relay

OFF state duration.

16. PROGRAM PARAMETER LIST

Loading...

Loading...