Chapter 8 Communications ASDA-B2

8-8 Revision May, 2018

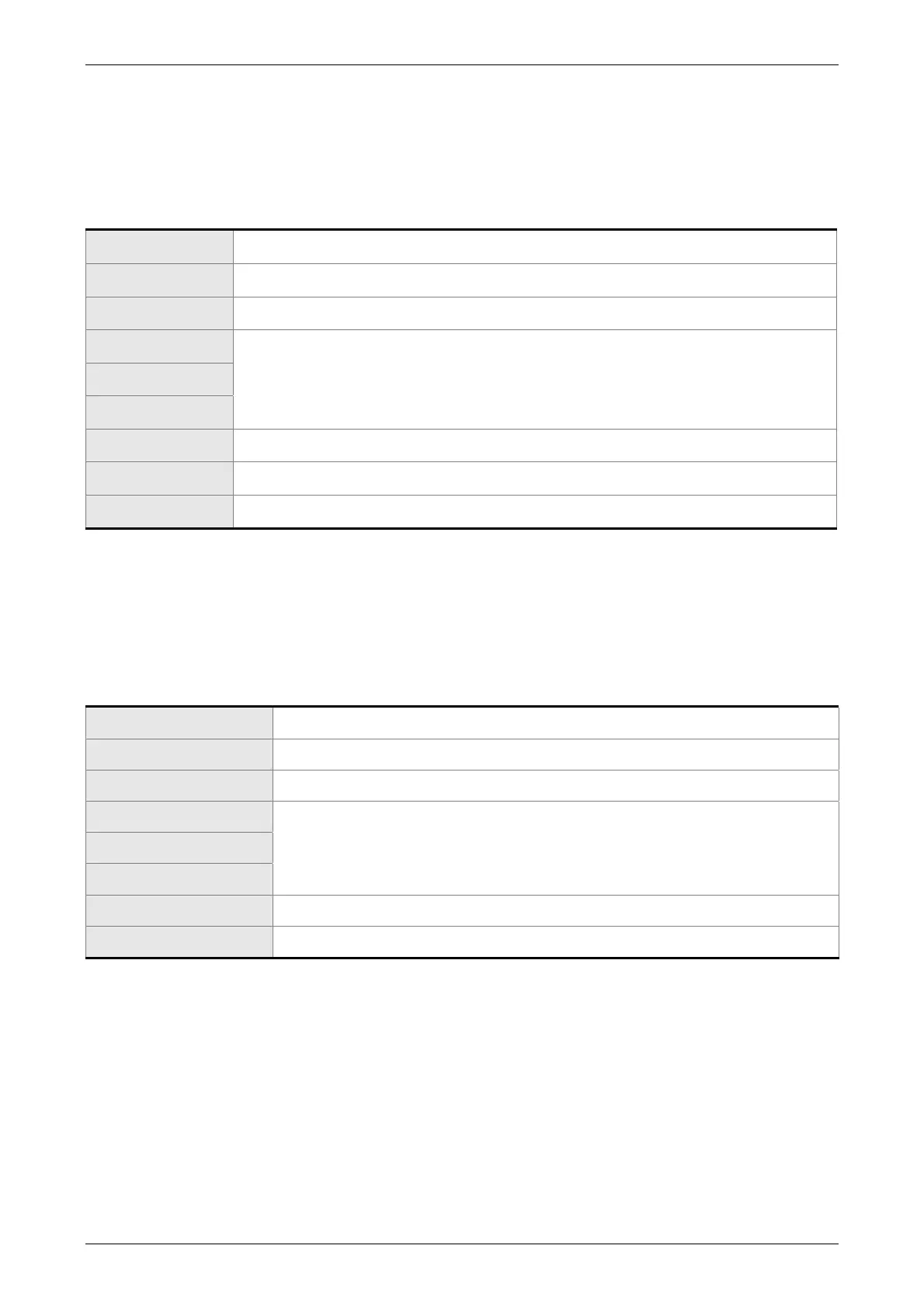

Communication Data Structure:

The data frame of two different communication modes is defined as follows:

ASCII Mode:

Start Start character’: ’ (3AH)

Slave address Communication address: 1-byte consists of 2 ASCII codes

Function Function code: 1-byte consists of 2 ASCII codes

DATA(n-1)

Data content: n word = n x 2-byte consists of n x 4 ASCII codes, n10

…….

DATA(0)

LRC Error checking: 1-byte consists of 2 ASCII codes

End 1 End code 1: (0DH)(CR)

End 0 End code 0: (0AH)(LF)

The start character of communication in ASCII mode is colon ‘:’ (ASCII is 3AH), ADR is

the ASCII code of two characters. The end code is CR (Carriage Return) and LF (Line

Feed). And the communication address, function code, data content, error checking LRC

(Longitudinal Redundancy Check), etc. are between the start character and end code.

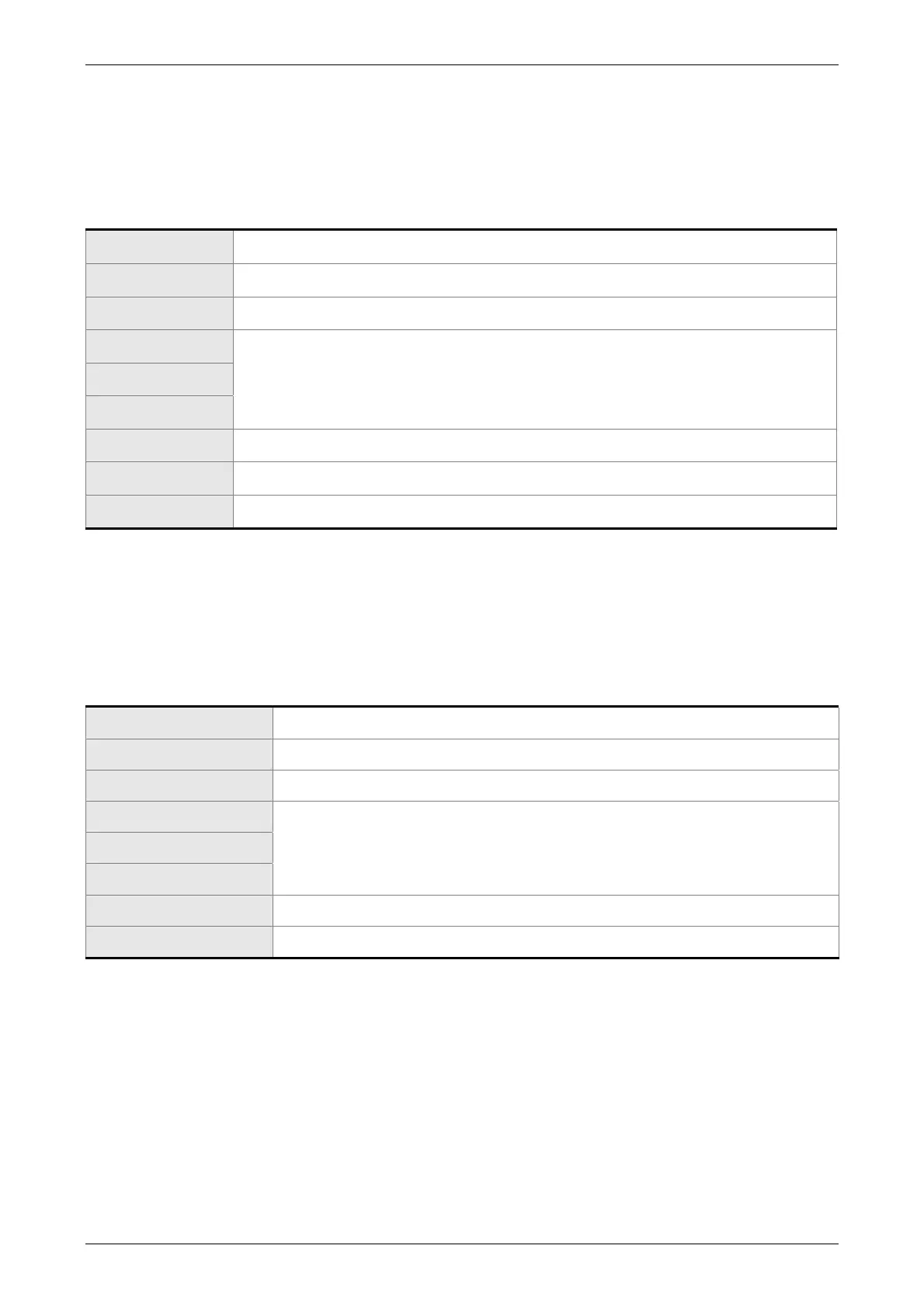

RTU Mode:

Start A silent interval of more than 10 ms

Slave address Communication address: 1-byte

Function Function code: 1-byte

DATA(n-1)

Data content: n word = n x 2-byte, n 10

…….

DATA(0)

CRC Error checking: 1-byte

End 1 A silent interval of more than 10ms

The start of communication in RTU (Remote Terminal Unit) mode is a silent interval. The

end of it is another silent interval. The communication address, function code, data content,

error checking CRC (Cyclical Redundancy Check), etc. are between the start and the end.

Loading...

Loading...