TECHNICAL REFERENCE MANUAL

3.4.3 Error behavior

The device has different error behaviors depending on the measuring characteristics and on the start operation.

3.4.3.1 A - Behavior

In case the device detects an error, this error is signalized at the outputs. On the serial and SSI output the error code will be visible

depending on the configuration. The error will be visible at the output until the device performs a successful measurement and outputs the

new distance value or the device will be reset by command (sNc) or by a power cycle.

3.4.3.2 B – Behavior (in moving target characteristic)

This error behavior is only relevant when using the moving target measurement characteristic.

Configuration

with error freezing

sNuc+2+0

1)

without error freezing

sNuc+2+1

1)

Situation

Temporary error The temporary error is converted into a

permanent error. This error must be reset as

described below.

The temporary error disappears as soon as the error

condition is cleared (a successful measurement is

done).

Permanent error The permanent error must be reset as described

below.

The permanent error must be reset as described

below.

The error reset function depending on the start condition. The following diagram shows the error reset for the different start configurations.

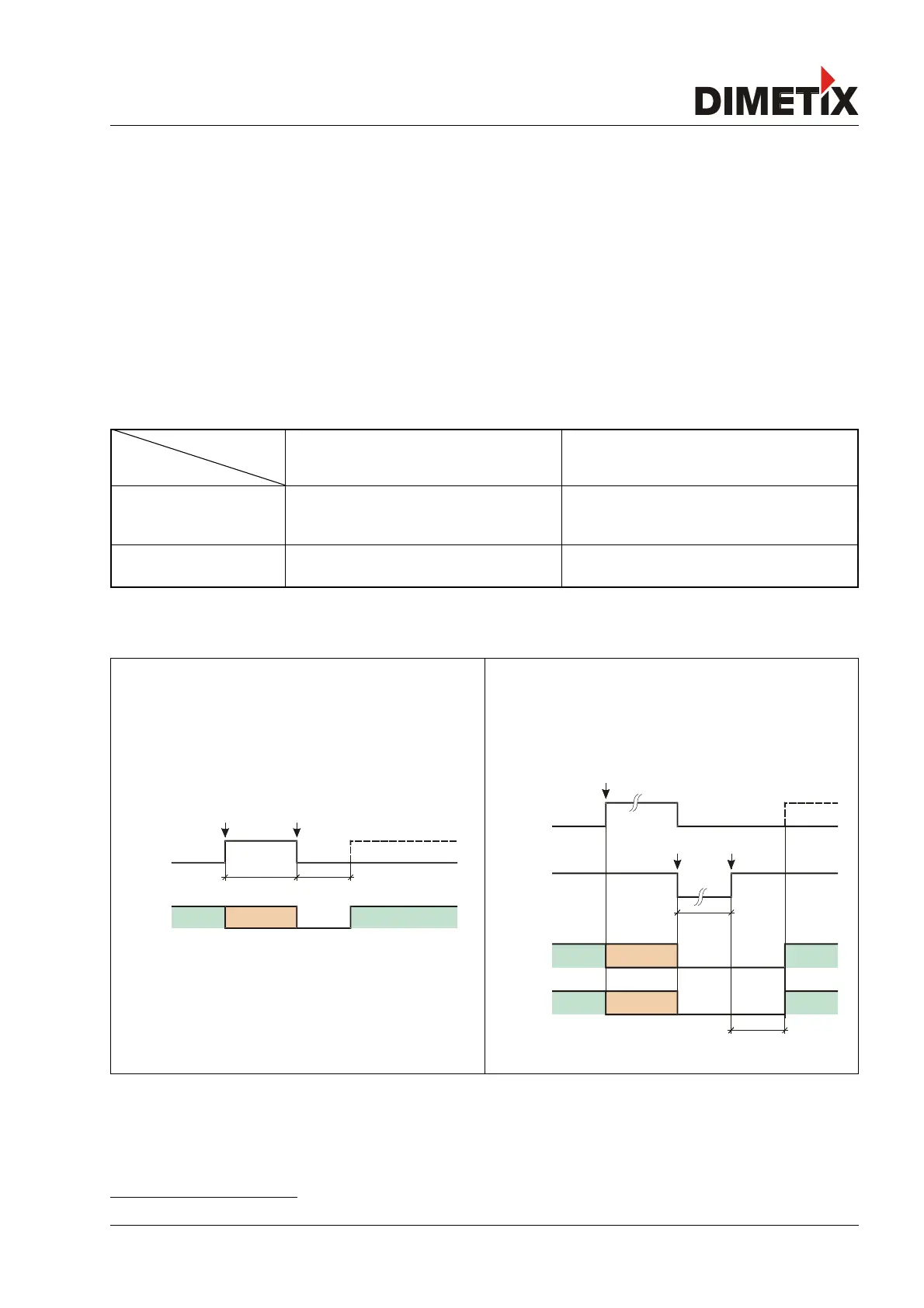

Stand-alone mode: Auto start configuration

(3.3.2.1 Auto start configuration on page 11)

In this operation the measurement starts automatically at power on.

A signalized error is reset automatically after 5 seconds. The reset is

done by an automatic restart of the device. This restart maximal

takes about 4 seconds.

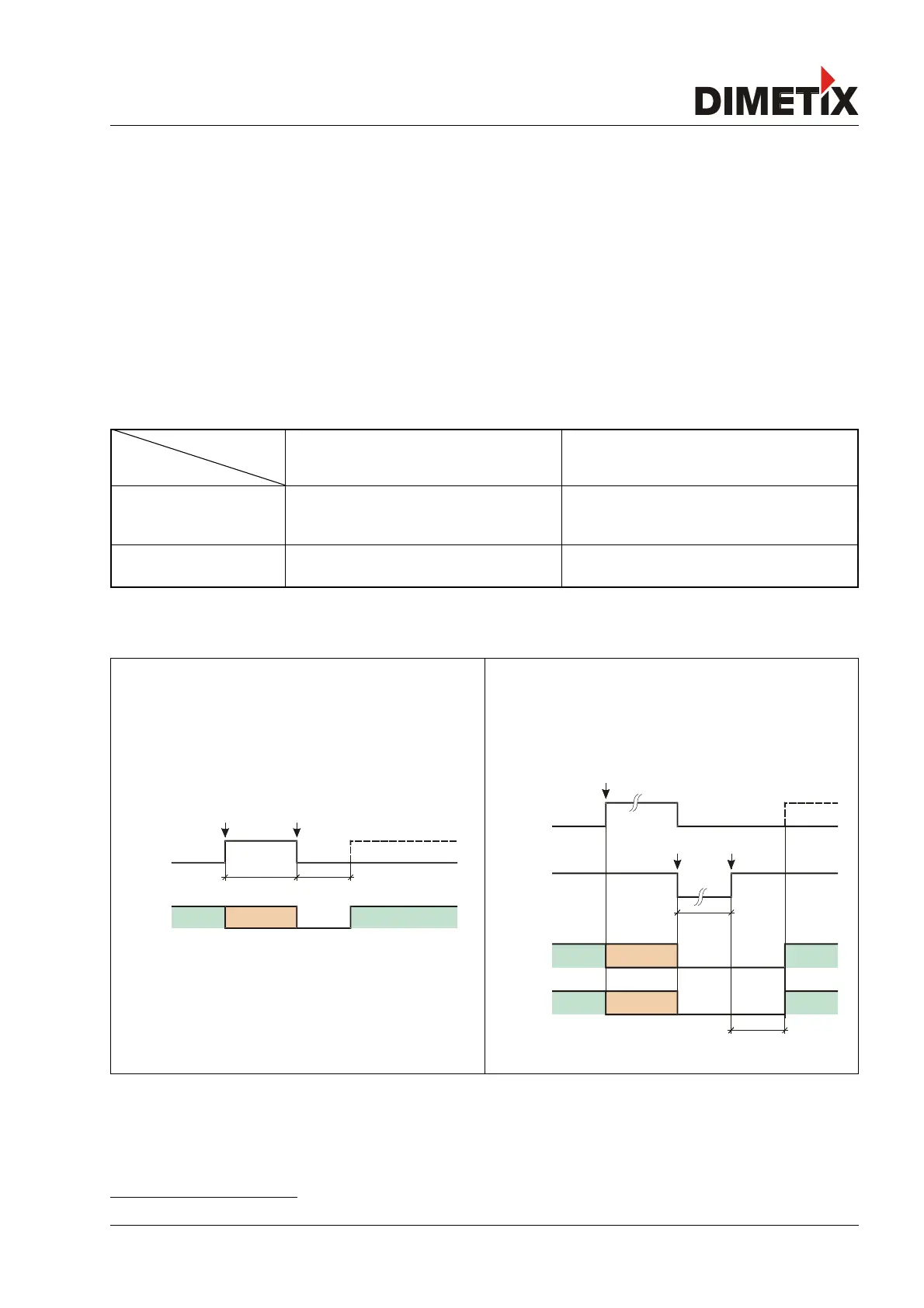

Stand-alone mode: Manual start configuration

(3.3.2.2 Manual start configuration on page 11)

In this operation the measurement is started with a digital input. In

case of an error, the reset of a signalized error is done by restarting

the measurement with the digital input.

1) For the description of the command see 9.3.2 Measuring characteristic configuration (sNuc) on Page 34

Distance Laser Sensor Page 14/53

Loading...

Loading...