28

Optimized layout for A4 print.

888888

1

3

4

2

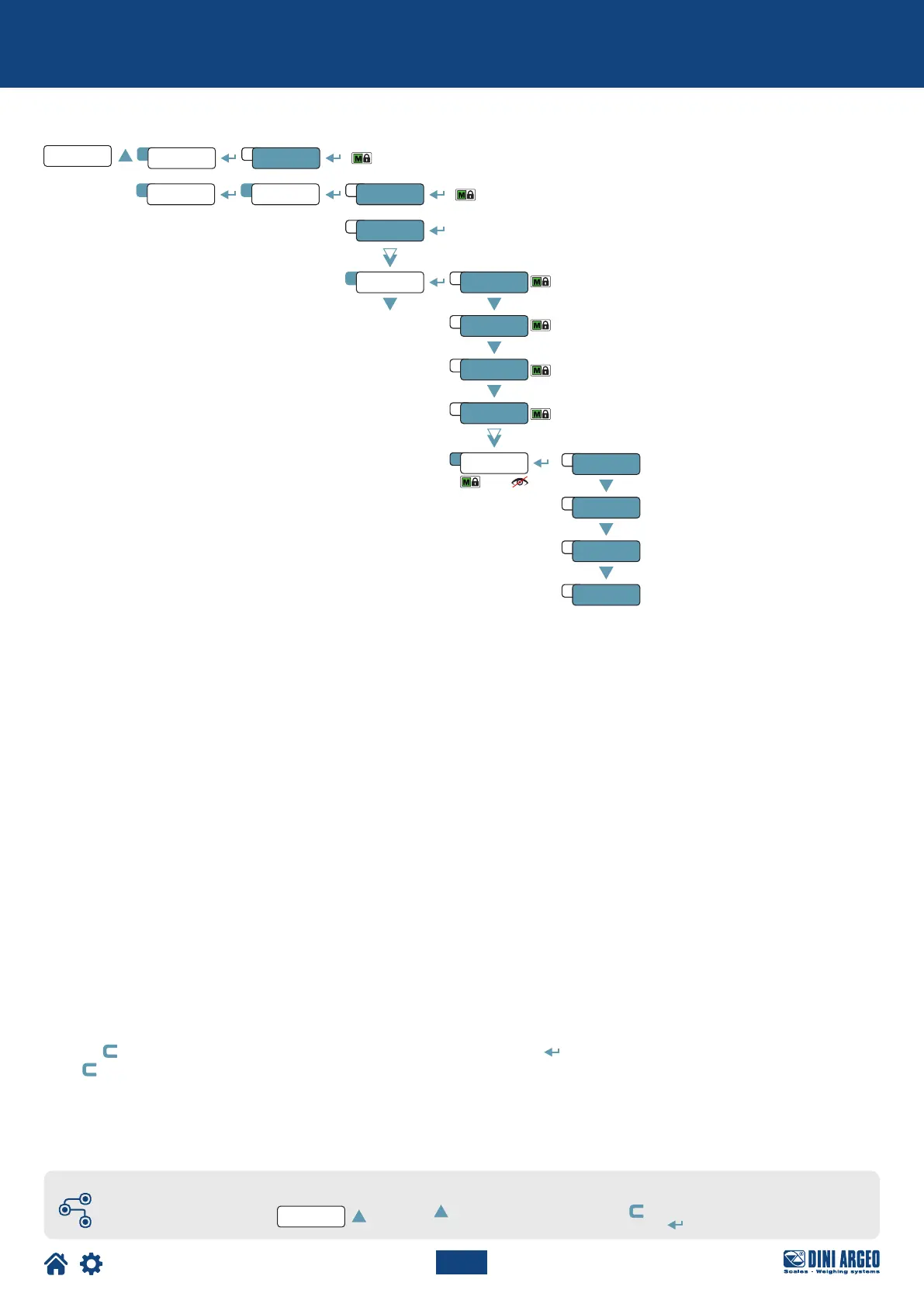

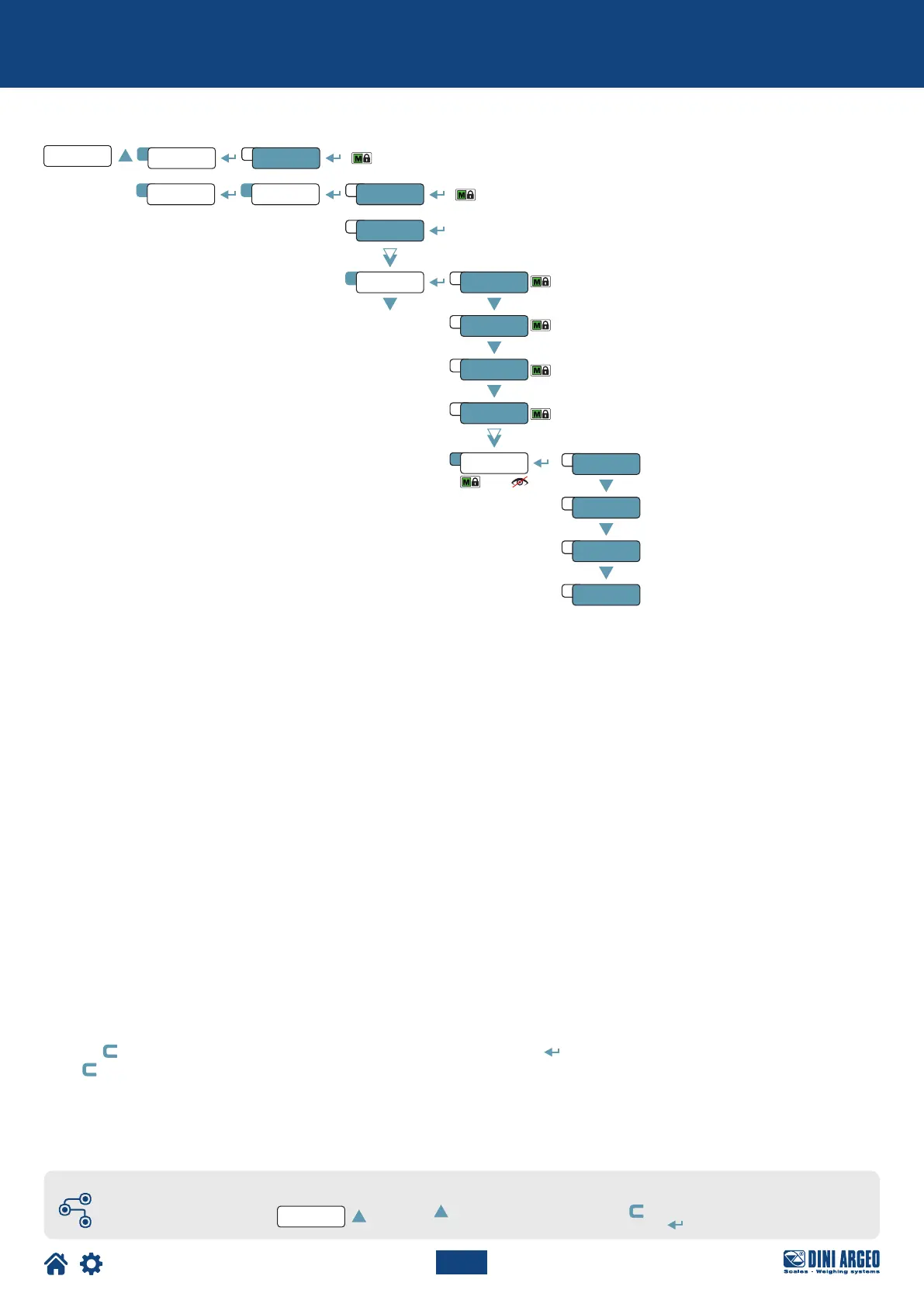

TYPE ind.Ch

A 2

888888

nChan

Chan

Setup

1

2

C

ConfiG

1

deCi

div

ranGe1

theo.Ca

u.m.

Calib

1

3

4

7

2

5

Cel.sen

Cel.CAp

dead.ld

kno.wGt

TECH_MAN_ENG_DGT4X

MENU ACCESS:

SAVING THE PARAMETERS:

Press the key during the start-

up procedure.

Press the key several times, until the display shows

SAVE?. Press the key to confirm.

Complete menu

on pages 24 - 25

Theoretical calibration

Independent channels

CALIBRATION PROCEDURE:

1. Select mode of use ind.Ch.

2. Set the number of connected scales (from 1 to 4).

3. Select the scale to be calibrated (from 1 to 4).

4. Set the calibration parameters:

deCi = Number of decimals.

u.m. = Unit of measurement (kG, G, t, lb).

div = Minimum division.

ranGe1 = Maximum range.

5. Set the cell data:

sen.Cel = Cell sensitivity (given by the sum of the value of each cell).

Cel.Cap = Total capacity of the cells (given by the sum of the value of each cell).

6. Enter the weight value of the structure in the dead.ld parameter. If you do not know this value, enter “0”.

7. If the structure contains a quantity of material whose weight value is known (e.g. full silo), enter this value in the KNo.WGT parameter.

8. Application of theoretical calibration:

Press the key to exit the calibration menu. The display shows th.Cal?. Press the key to confirm the use of the theoretical calibration,

or the key to cancel.

9. Repeat the procedure from point 3 for each scale to be calibrated.

Loading...

Loading...