16

※ Note) Thickness adjustment for L/M Guide Block Liner (Y-Z)

(1) Refer to the “Y-Z squareness”above to measure the exact squareness.

(2) Calculate the amount of Liner polishing by calculating the length of square

ruler and the distance between the Z-axis L/M Guide’s two Blocks.

▪ Since the distance between the two L/M Blocks is 450mm, multiply the

squareness measurement by 1.5.

(3) Take out the liner after sorting the upper or lower side L/M Block and

reassemble it after adjusting it (polishing on the spot) as calculated above.

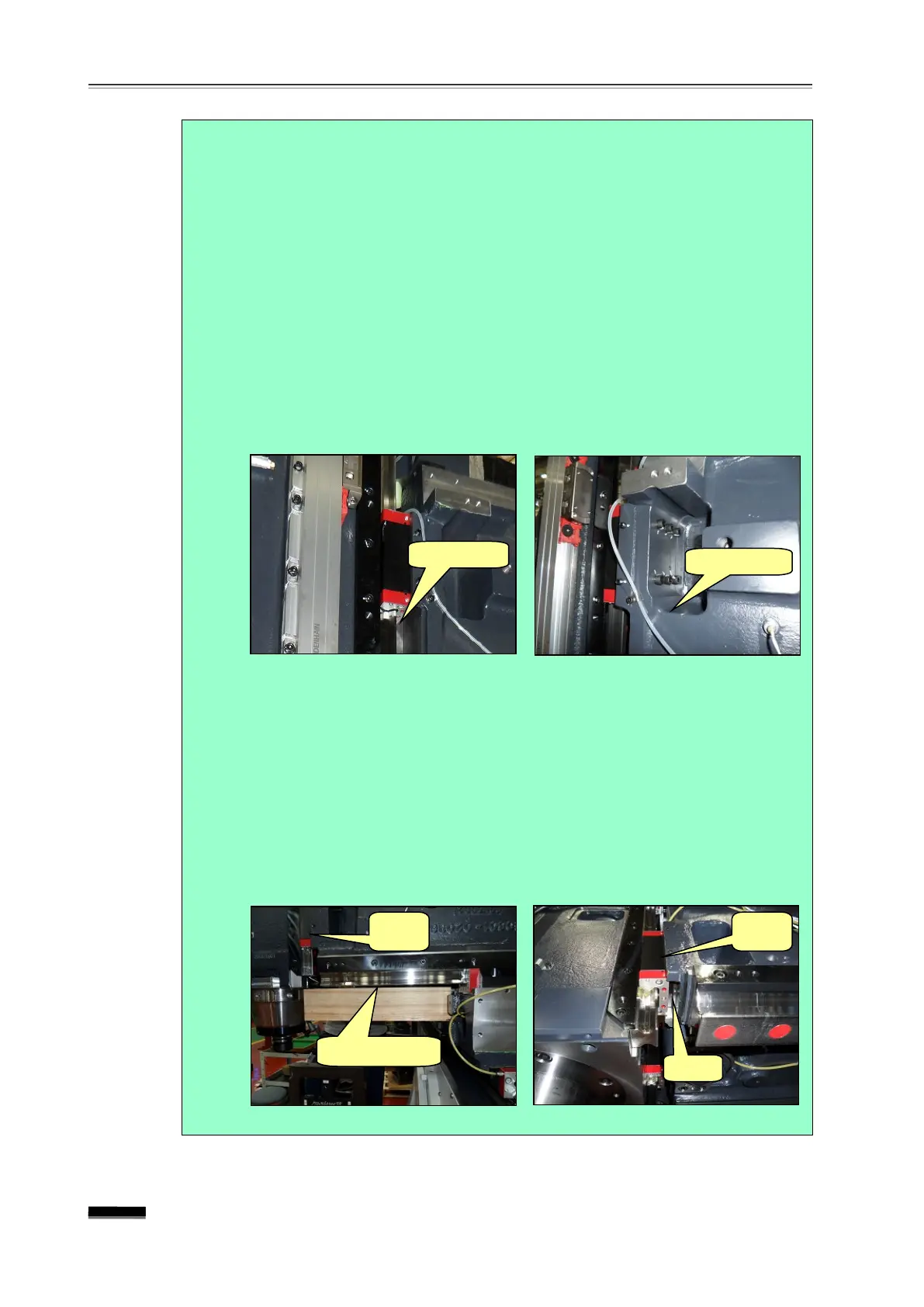

① If the ⓐ part is “+,” completely take out the 3 outer side bolts from

among the 6 fixing bolts on the upper side L/M Block and slightly

loosen the 3 inner side bolts, and then remove the Liner upwards.

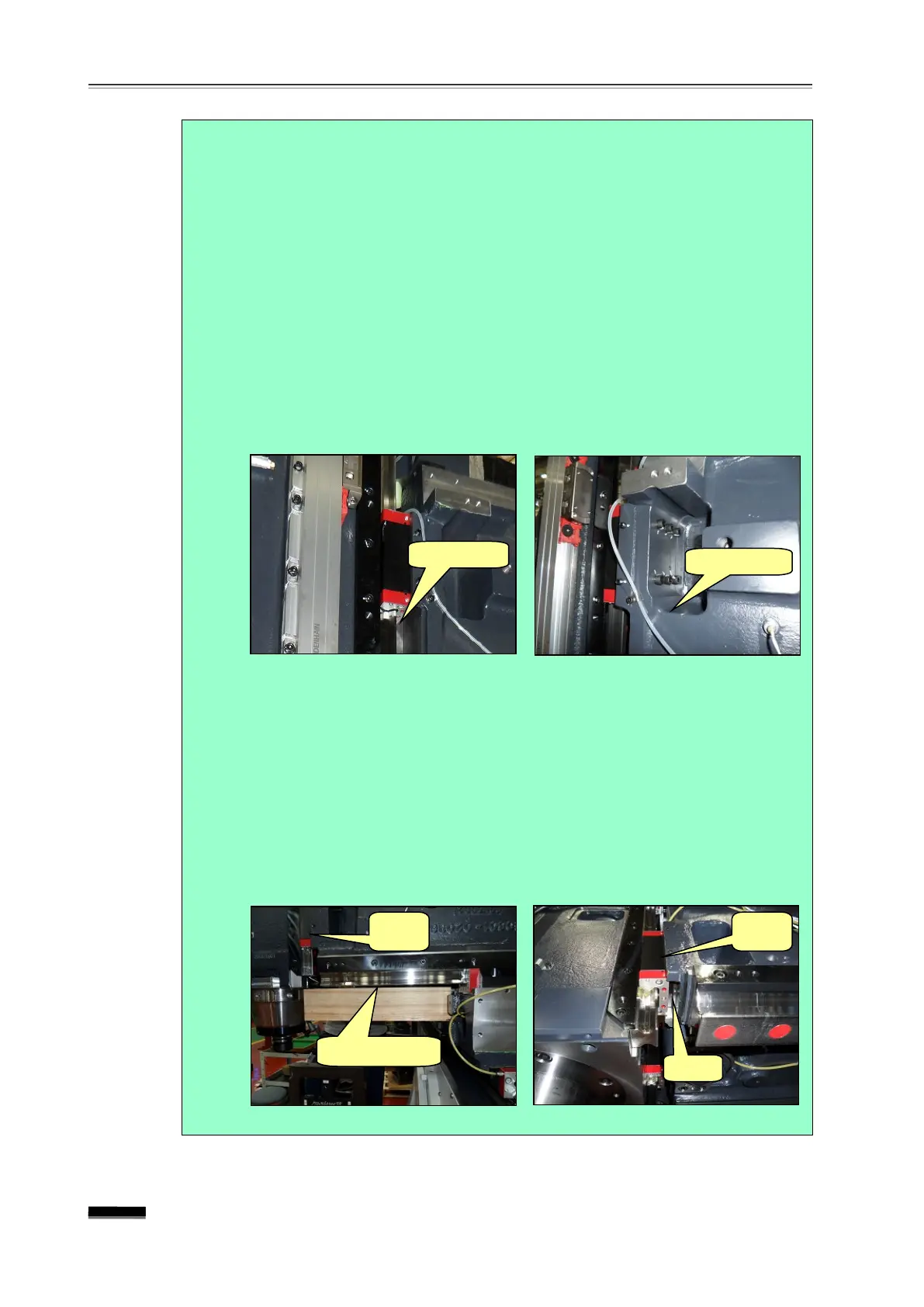

② If the ⓑ part is “+ ”, first insert a support (wood) with a length of about

400mm into the lower part, slightly apply force to the spindle head by

moving the Y-axis, fully remove the two lower bolts from among the 4

lower side L/M Block fixing bolts, slightly loosen the two upper bolts,

and then take out the liner to the bottom.

▪ If the liner gets caught and cannot be removed easily, remove the liner

while moving the Y-axis in the “- ” direction in the Handle Mode by

0.01mm increments.

Loading...

Loading...