33

5. Machine Leveling

5.1 Machine absolute level operation

’s Zero Point Setting

① First, place the level at the center of the table and read the dimension of one part of

the level droplet accurately.

② At the same po

sition, rotate the Level 180 ° to read the droplet dimension in the same

direction.

③ Use the “- ”

screwdriver to rotate the origin adjustment screw so that the middle of the

droplet dimension (halfway between the two directions) between the first droplet

dimension and the droplet dimension when turning 180˚can move.

④ Repeat ①∼③

in order to make sure to adjust the water droplet to the same position

when turning in both directions.

※ How to read Level (example)

End position of right hand side water droplet

+End of left hand side droplet ÷ 2=Level

dimension (-50 + -40)÷2= -45

▪ The above level is 45 μ/m higher on the left.

※

When setting a level or leveling a machine, it

is a good practice to read the standard level

instead of reading the one on one side.

“

“

“

”

※ Note) Matters to be noted when performing the level operation

Prior to starting absolute level operation for 5-axes machine, be sure to check

the table top accuracy in advance, and correct in case of any irregularity.

▪ Table top accuracy check

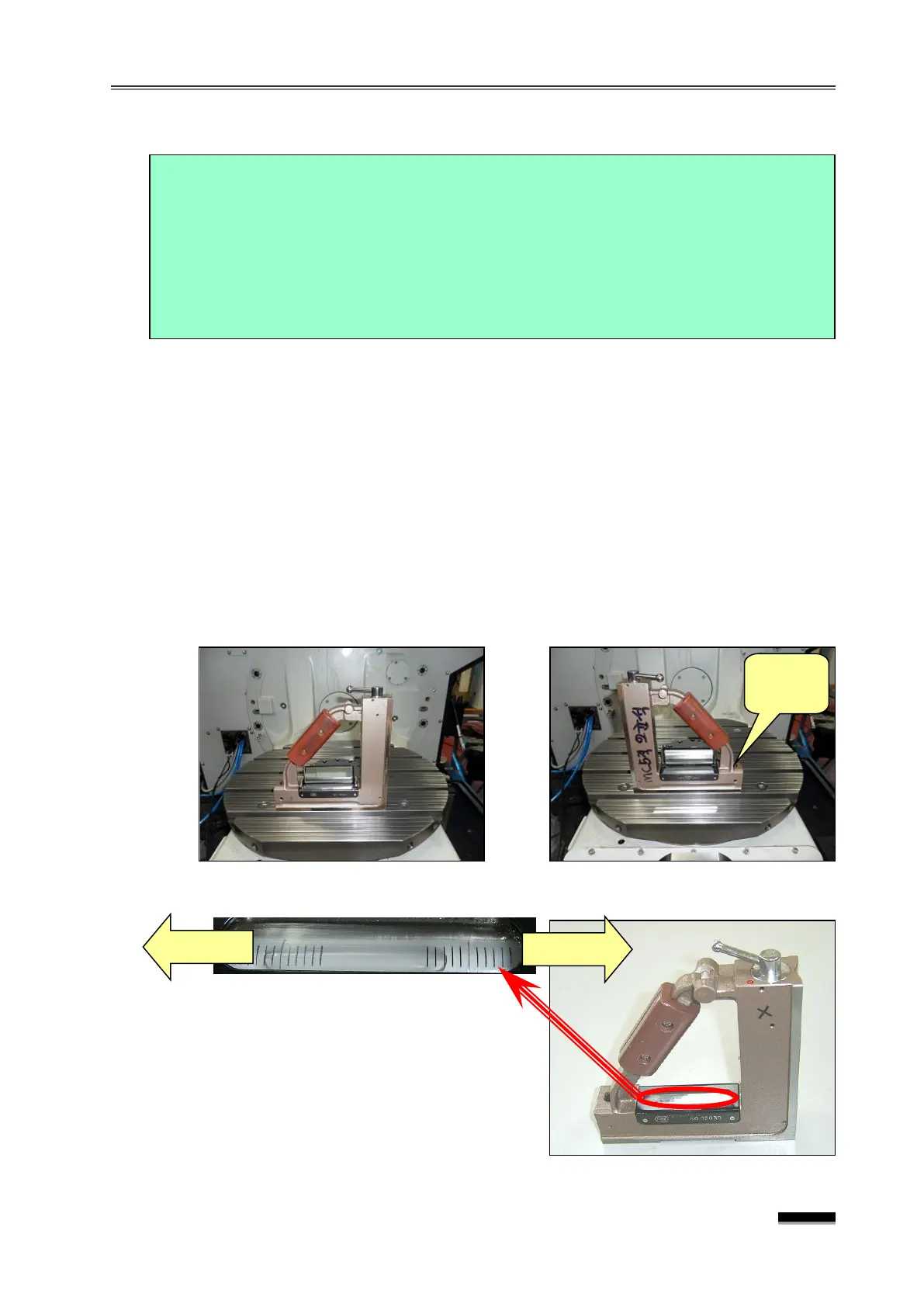

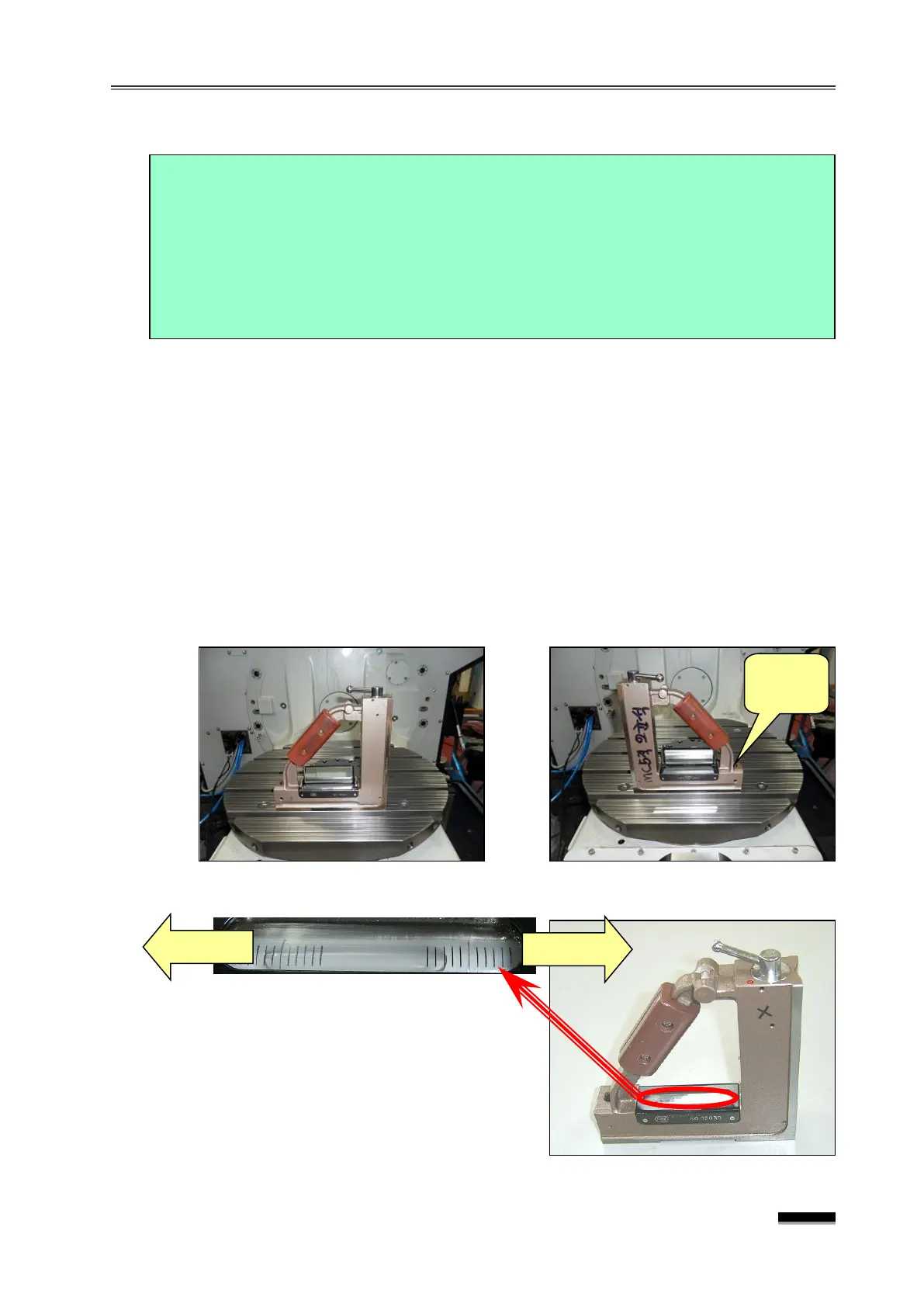

(1) B-axis machine reference point

(2) Height difference in Y-axis direction table

Loading...

Loading...