86

7. Adjustment of reference points of respective axes and manual TCP adjustment

7.5 DCP-i compensation

What is DCP-i compensation?

When applied to 5-Axis machining tools, this function makes it possible for the

workpiece and tool tip positions to remain unchanged regardless of whether the rotation

axis is rotating or not. It uses a touch probe and a mast ball to automatically measure

the measurement and compensation and to minimize geometric errors.

▪ DCP-i : DOOSAN Rotation Axis Center Point Compensation-Inteli

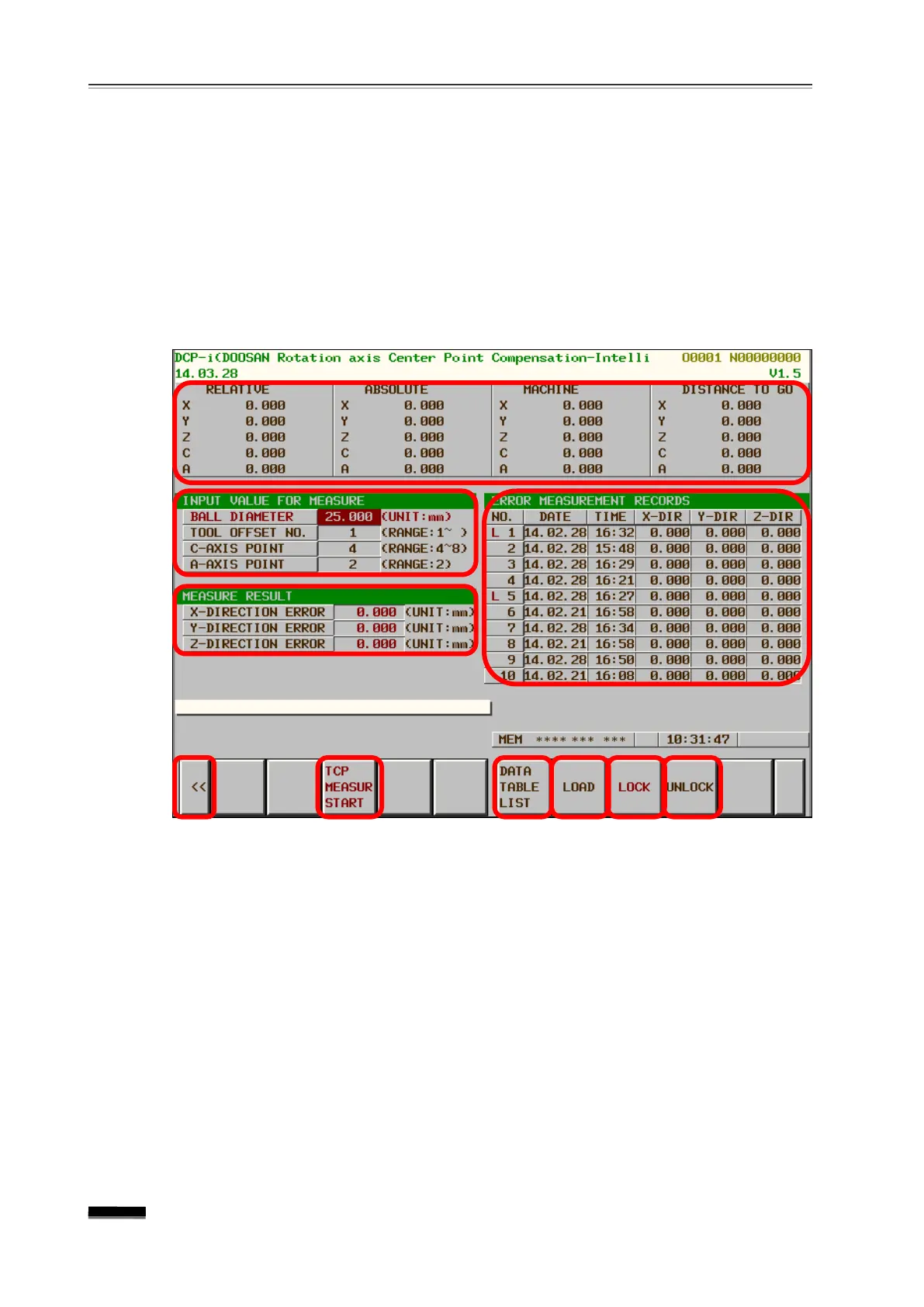

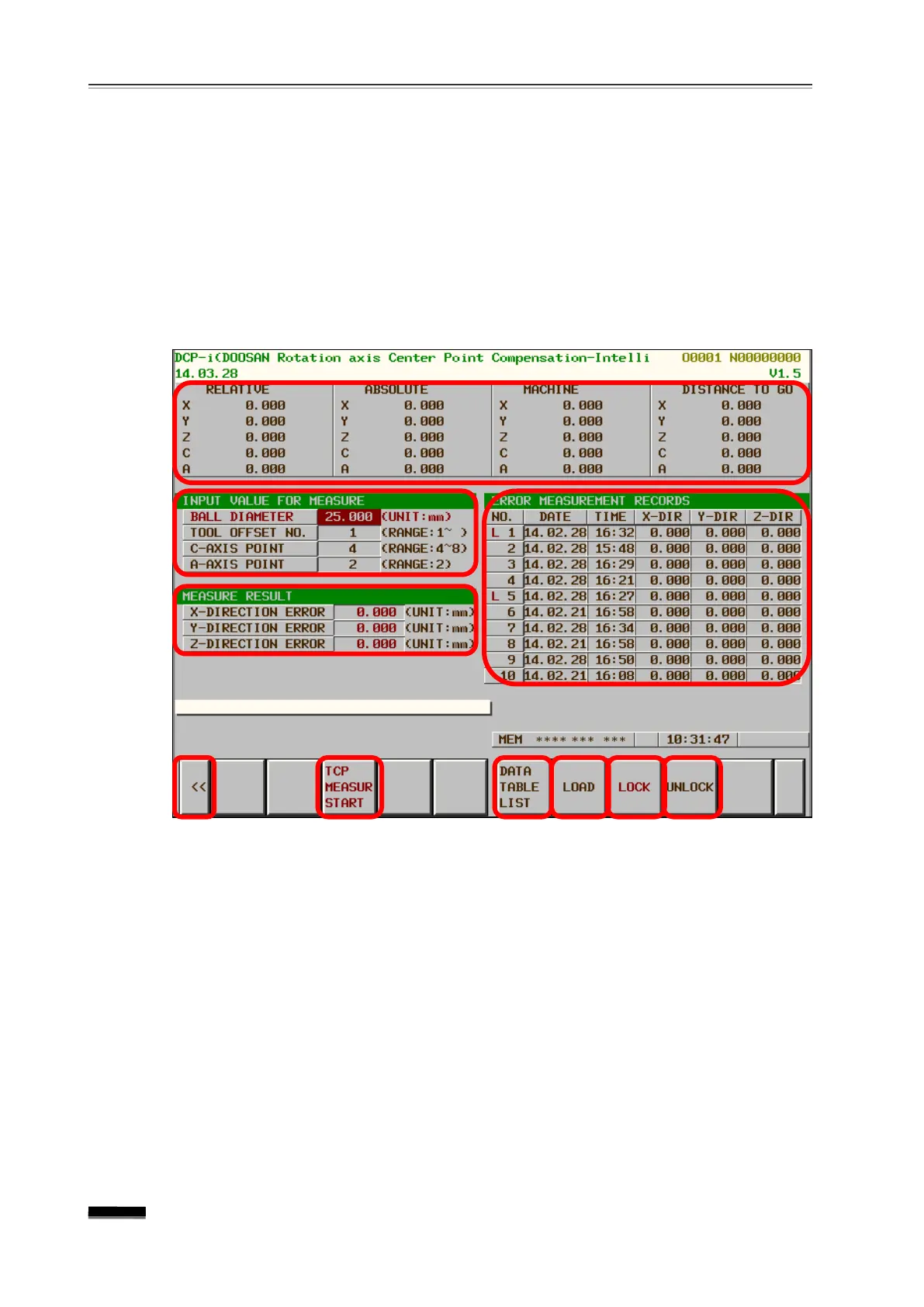

-i Main Screen

① Indicates the relative coordinate system, absolute coordinate system, machine

coordinate system, and moving distance when measuring.

②

The ball radius before measurement, the

touch probe tool number, and the number of

measurements on the C axis / B axis within the range shown on the right can be set.

③ After taking the measurement, the results of any X / Y / Z axis measurement errors

displayed.

④ In the case of Parameter Save “Y ”

for the measured error value, automatically saved

in Data Table. (In the case of (“N”), not saved.)

⑤ Soft key for returning to the Package Software Main Screen.

⑥ Soft key for starting the TCP measurement.

⑦ The cursor can be moved to the stored Data Table on the right.

Loading...

Loading...