81

7. Adjustment of reference points of respective axes and manual TCP adjustment

7.2 Z-axis reference point resetting (Z-axis Stroke: 400mm)

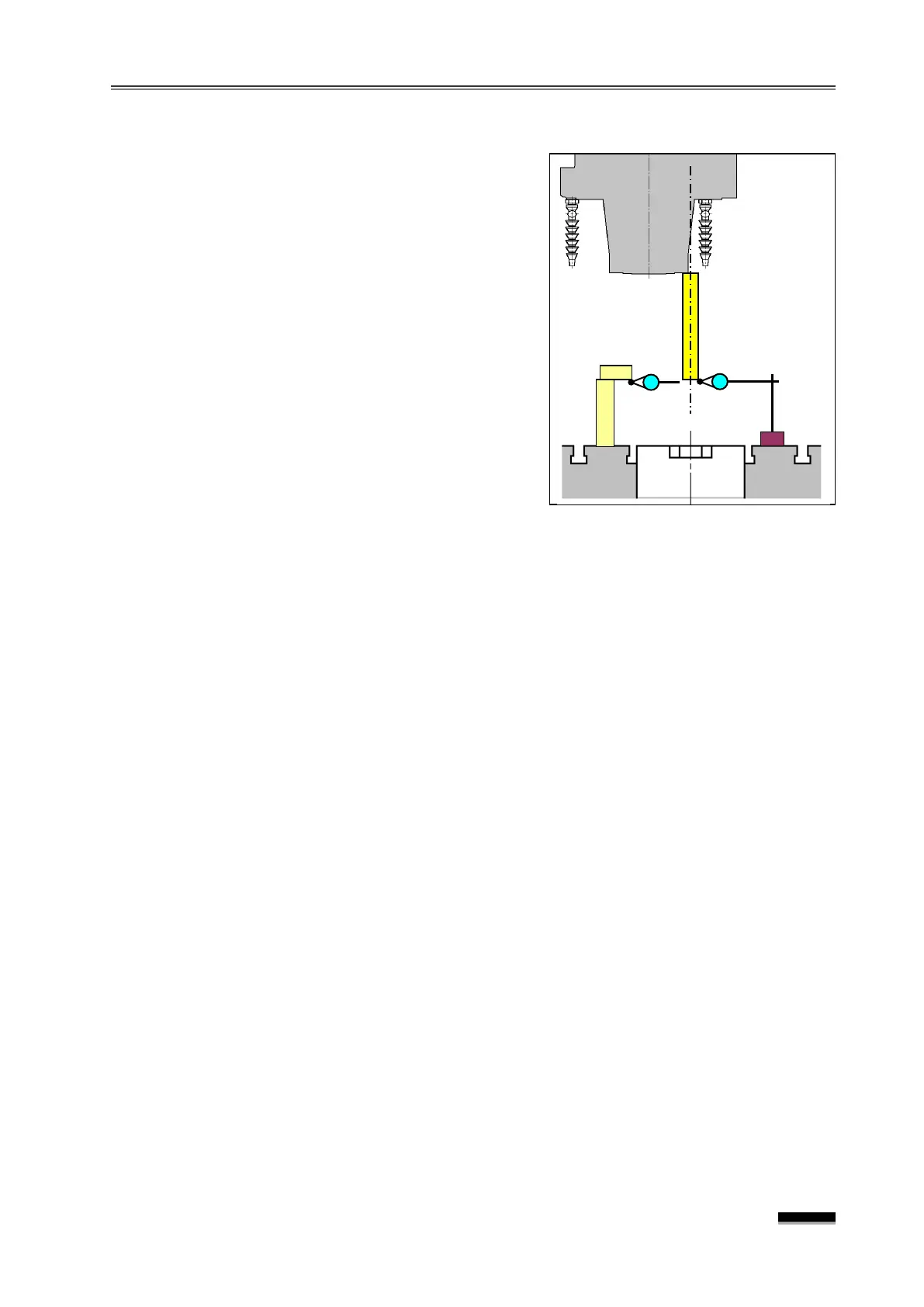

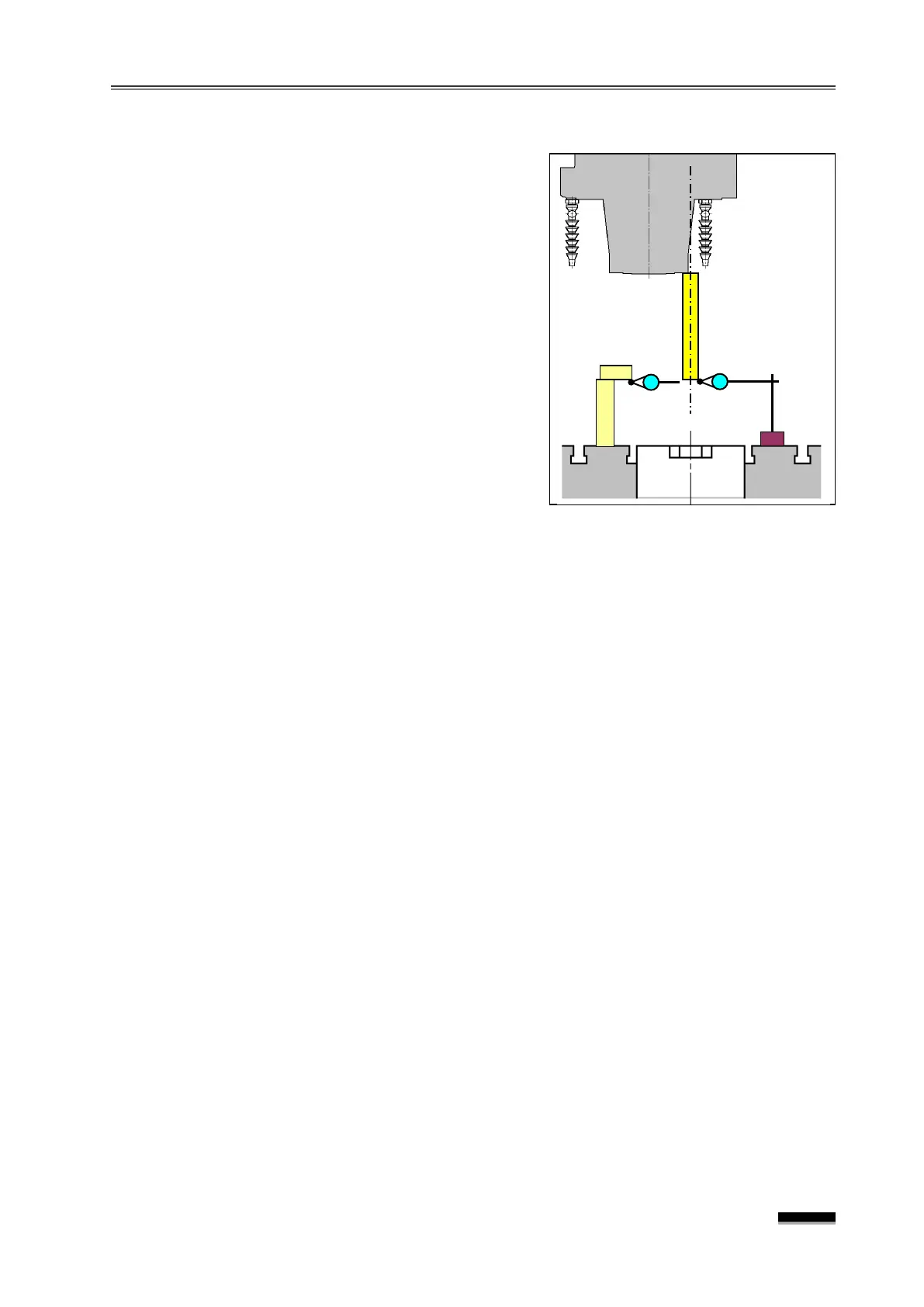

-bar into the spindle, set up a block

gage (around 100mm) so that the

measurement can be made from the bottom,

and set the indicator to

“0.”

-axis in the Handle Mode, so that

the end of the Test-Bar touches the indicator to

set it to "0".

3) Calculate the distance from Z0 position by the

following equation.

Test Bar Length

Block Gage Height - 150

▪ For the DVF 5000, when the distance from

the table top to the Spindle Gage Line is

"150mm,” “Z-400.000”

Ex) If the Block Gauge : 100mm, Test bar : 310mm, then : 310 + 100

150 = 260

In other words, in this case, the position reached when -260.000 has been

transferred in the Z-axis machine coordinate is -400.000, which is the end of the Z-

axis stroke “- ”

direction. And, for the machine reference point position, the position

reached when 140.00 has been transferred in the + direction is the Z-axis

reference point.

’s position on the CRT screen and enter the error amount into the

Parameter No.1850 Z-axis field.

▪ If the Parameter already has a certain number, “+Input” the error amount.

☞ In this case, if the Parameter #1815 “X” or “B” field b4(APZ) changes from “1”

“0”, the “PW0000 POWER MUST BE OFF” and “P/S Alarm 300 nAxis Need ZRN

alarms will be activated on the screen.

the Z-axis with the “JOG” or

HANDLE

feed in the direction of reference point

return to a position near the front of the reference point mark (within 1Grid : within

10mm).

▪ Rapidly move the axis by several Grids or more.

While pressing the

JOG+

switch of the Z-axis in the

R E F. RTN

Mode, perform

reference point return in the “+ ” direction. (Keep pressing the

JOG+

reference point return is complete and the axis stops.)

☞ b4(APZ) of the “Z ” field of the parameter #1815 changes from 0” to “1”

alarm is cleared.

the Z-axis to the Z-260 position, measure as above, and if the

measurement is within +0.005mm, complete the reference point return.

Loading...

Loading...