36

5. Machine Leveling

5.2 Machine Feed Level Operation

1) Machine feed level operation jig installat

ion and reference point setting

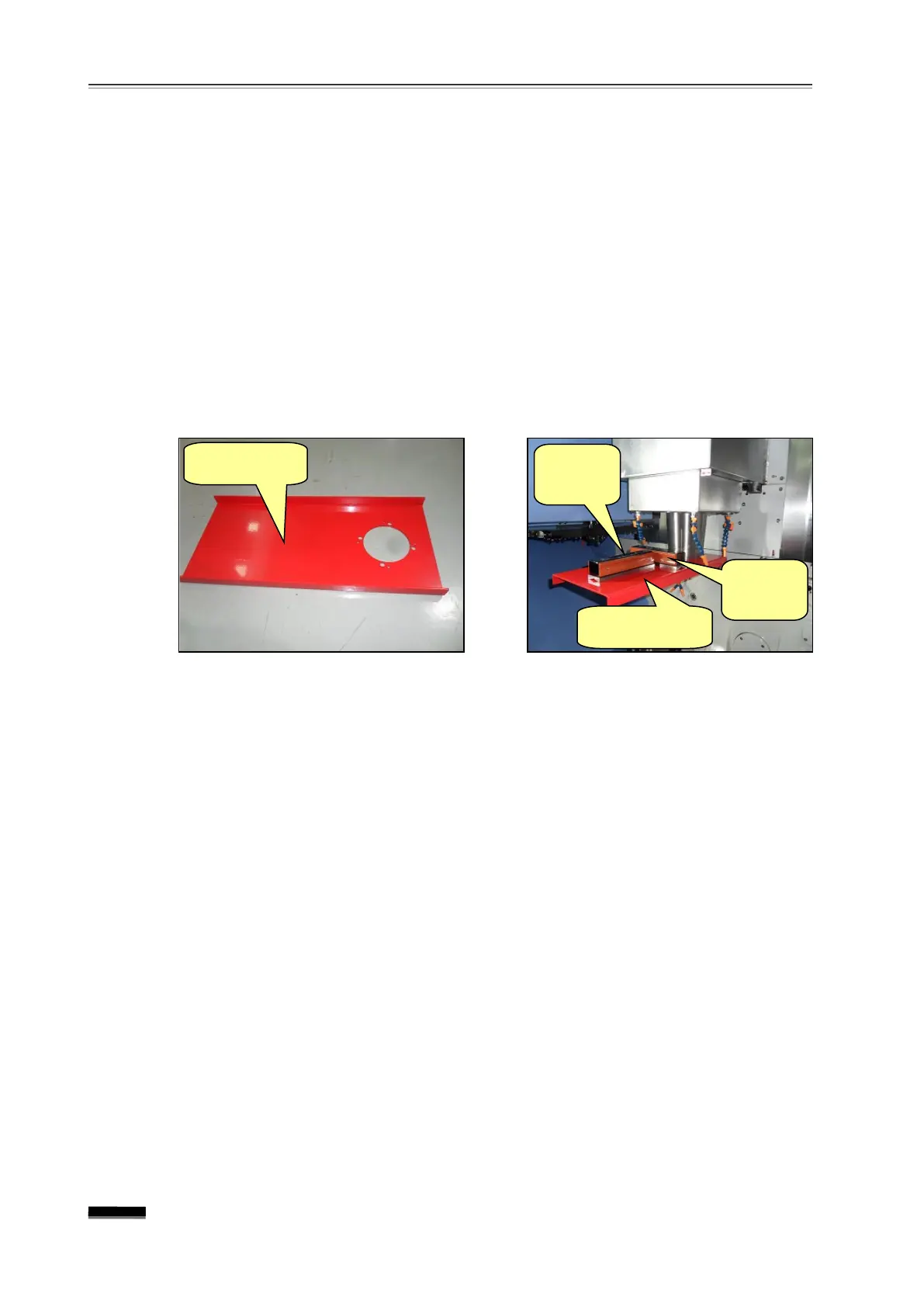

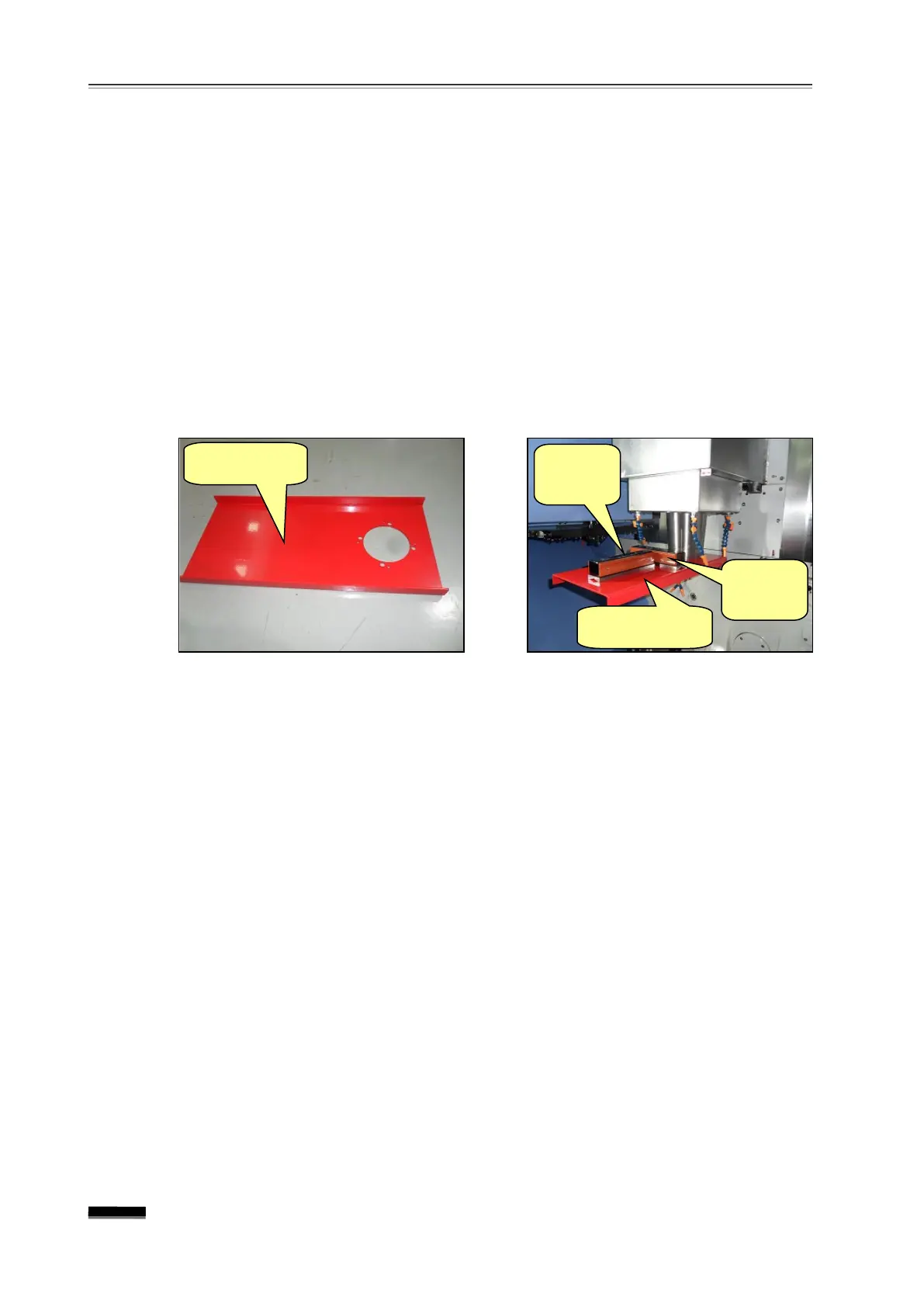

① Prepare the level installation jig which is one of the basic items shipped and

assemble and secure the jig on the front cover surface under the spindle in Y-axis

direction.

② Place levels on the assembled level installation jig in X- and Y-axes direction.

③ Use a screw driver to turn the reference point adjusting screw on the level, making

adjustment until the air bubble on the level comes to the middle.

▪ If the level installation jig is worn and deformed a lot, making it difficult to make

adjustment with the level reference point adjusting screw, place papers on one side

under the level to let the air bubble come to the middle.

2) Machine Feed Level Operation

① Move the whole sections of X- and Y-axes by equally dividing X- and Y-axes into

three subsections respectively and perform the level operation while checking

differences for 9 subsections after feed level.

▪ In general, if an equal torque was applied to each level bolt during the machine

absolute level operation, there should be no problem in the machine feed level,

however, in case of any irregularity, keep performing level adjustment while

watching feed level.

※ It is a good idea to create a program before doing the leveling work.

G90 G00 G54 X0. Y0;

M01 ;

X-275. Y225.;

M01 ;

X0.;

M01 ;

X275.;

M01 ;

Y0.;

M01 ;

Y-225.;

M01. ;

X0.;

M01 ;

X275.;

M01 ;

Y0.:

M01;

M99 ;

direction

direction

Loading...

Loading...