77

6. Machine Accuracy Measurement and Adjustment

6.15 Run-Out of Spindle Internal Diameter

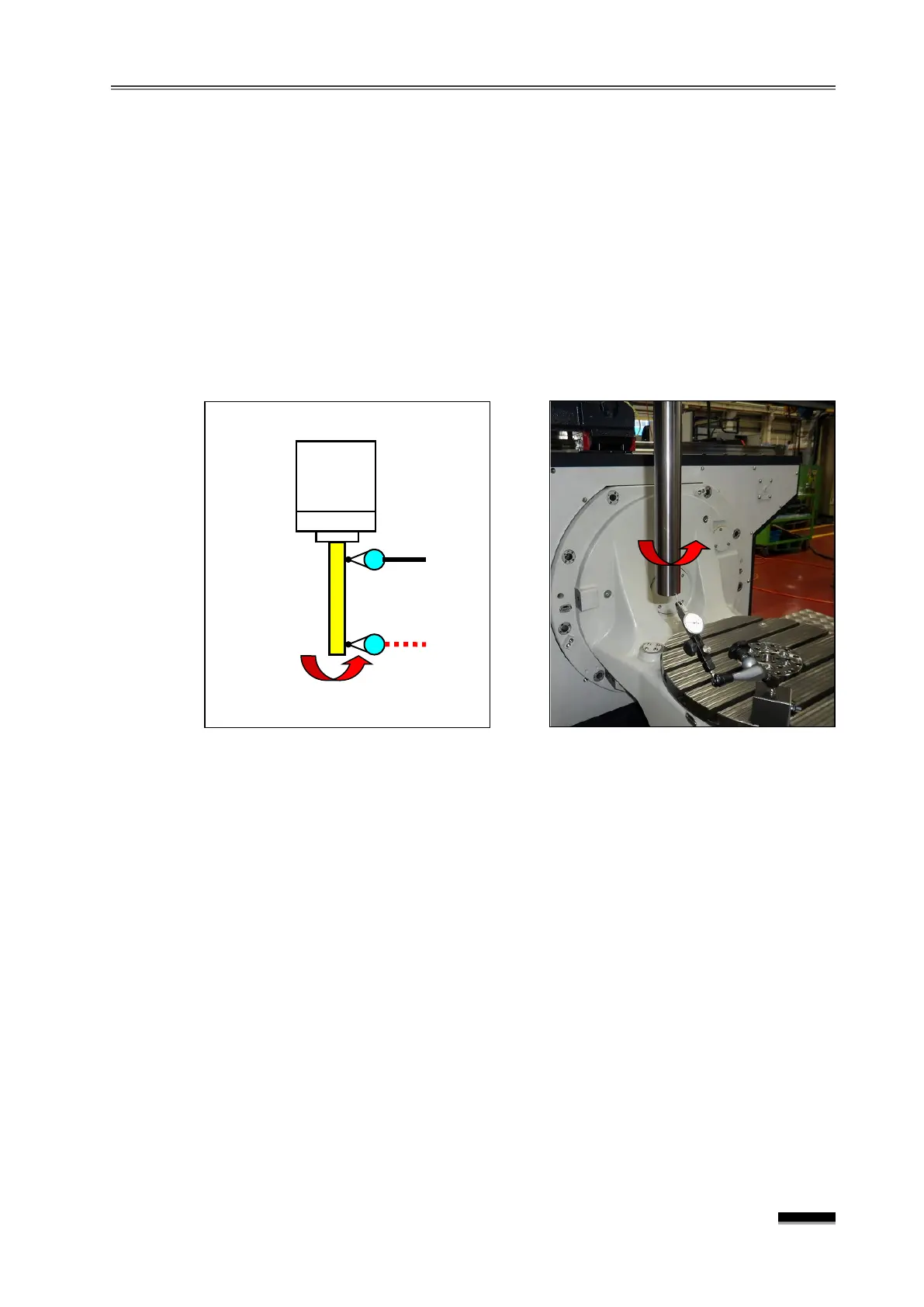

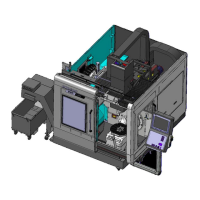

Install the test bar on the spindle and turn the spindle at low speed or manually, with the

indicator touching the entrance and at 300 mm from the entrance. Rotate the spindle

manually or at low speed to measure the run-out, and take the maximum run-out as the

measured value.

▶

Measurement position : Test-Bar entrance and 300 mm from the entrance

▶

Tolerance : Entrance : 0.005 mm,

300 : 0.012mm

① Because there is a possibility of dents etc. forming on the spindle taper surface,

remove the pull stud using a test bar or a new tool, apply a thin red lead or stamp

pad to the taper portion, rub the taper surface against another, and, from the touched

traces, smooth the dented areas using sandpaper.

※ You must not polish the taper surface with a grinder or such like, and when the

taper surface is seriously damaged, the spindle must be re-polished.

② Touch an indicator to the Spindle Taper surface to check Run-Out. If the

measurement exceeds 0.005 mm, the Spindle Main Bearing or the Main Spindle

could be the cause of the problem. Replace or repair the bearing or the spindle if

necessary.

300 mm

position

Loading...

Loading...