45

6. Machine Accuracy Measurement and Adjustment

6.3 Straightness of Z Axis Movement

- Y plane

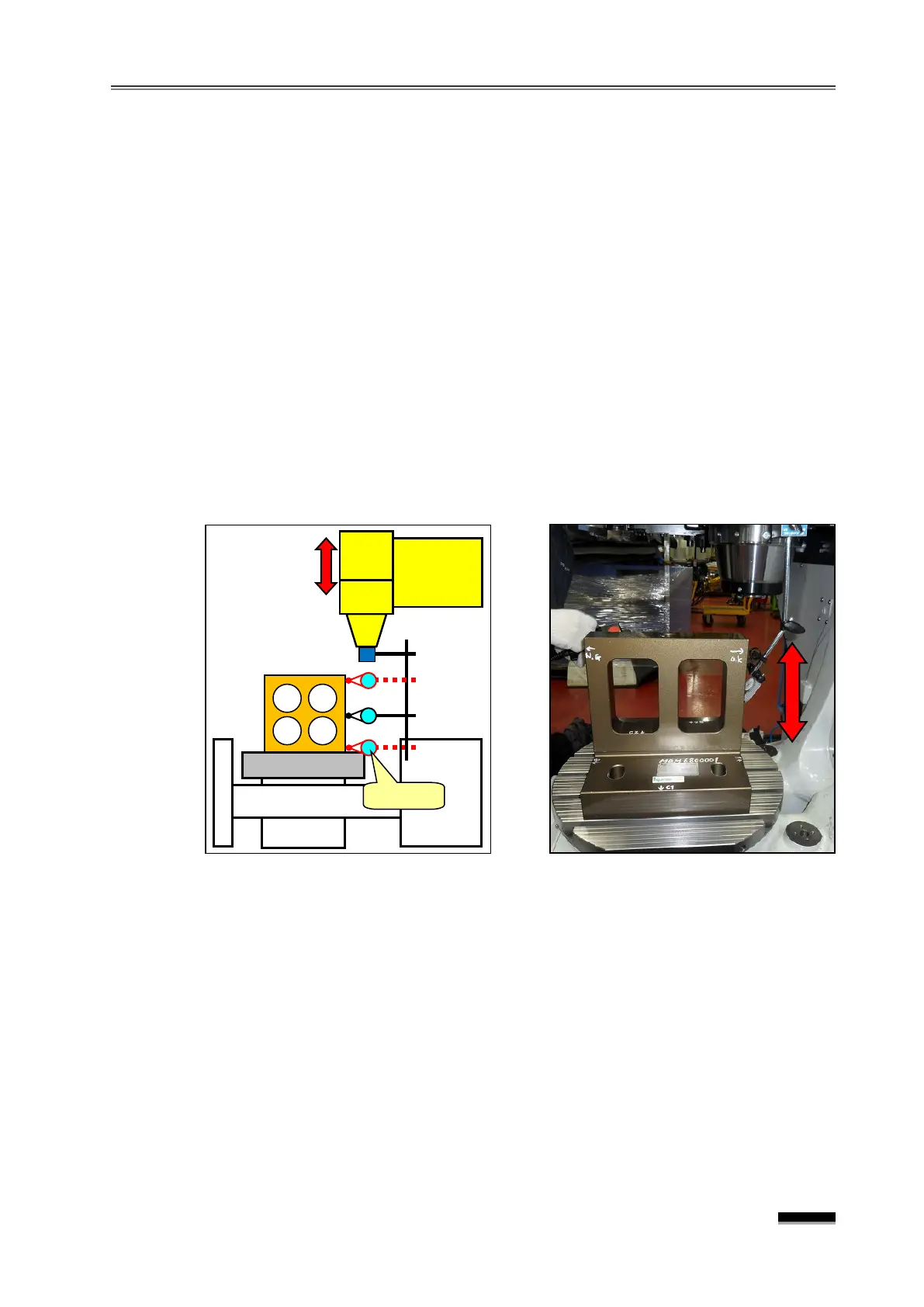

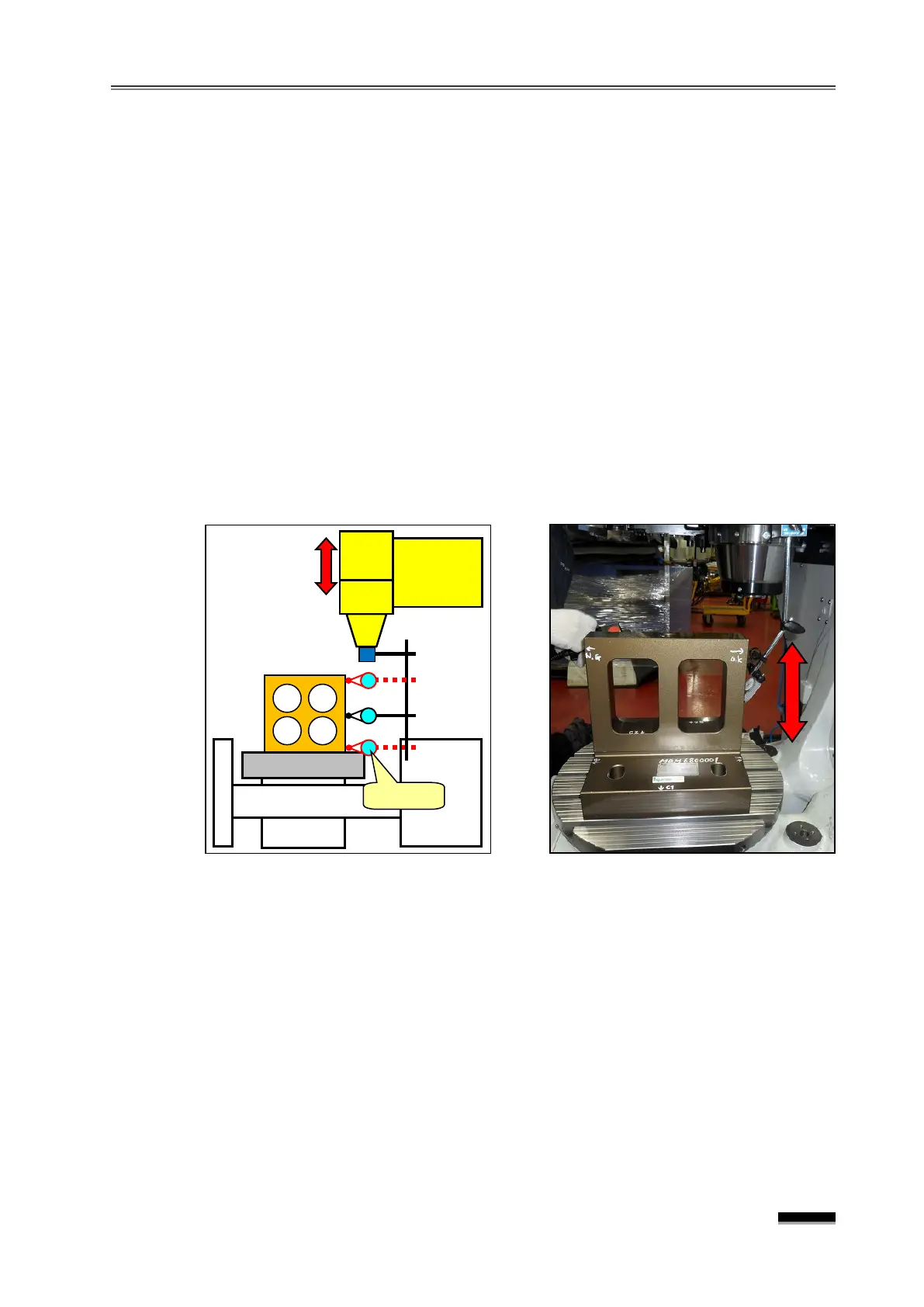

① Measurement

Place a square ruler in the upright position on the table in the Y-axis direction at the

B0. position, set the indicator to “0” at the end of the vertical plane on the square

ruler by setting up an indicator on the spindle head, and then measure the maximum

difference (i.e. the measurement in the middle) while moving the Z-axis.

▪ If the measurement value is not “0”

when measuring the other end with one end set

to “0,” take half the error amount as the measurement value.

※ When measuring the Y-Z squareness, measure three positions on the Y-axis

plane of the square ruler.

▶ Measurement position : Both ends and the center of the square ruler.

▶ Tolerance : 0.005mm / 300mm

② Adjustment

If the straightness on the Z-Y plane of the Z-axis is wrong, a possible cause may be

Z-axis L/M Guide defect or L/M Guide misalignment, in which case it will be

Loading...

Loading...