44

6. Machine Accuracy Measurement and Adjustment

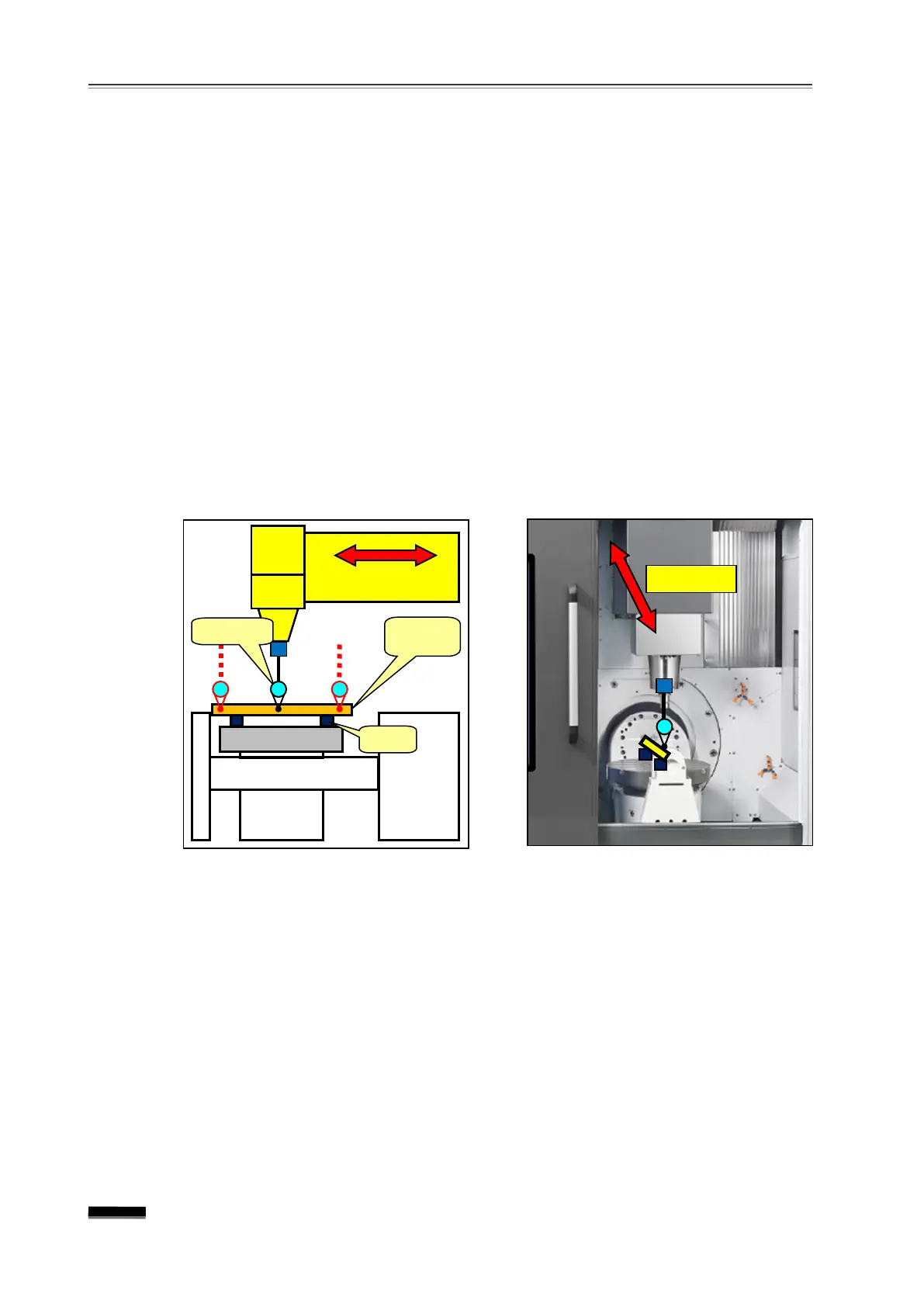

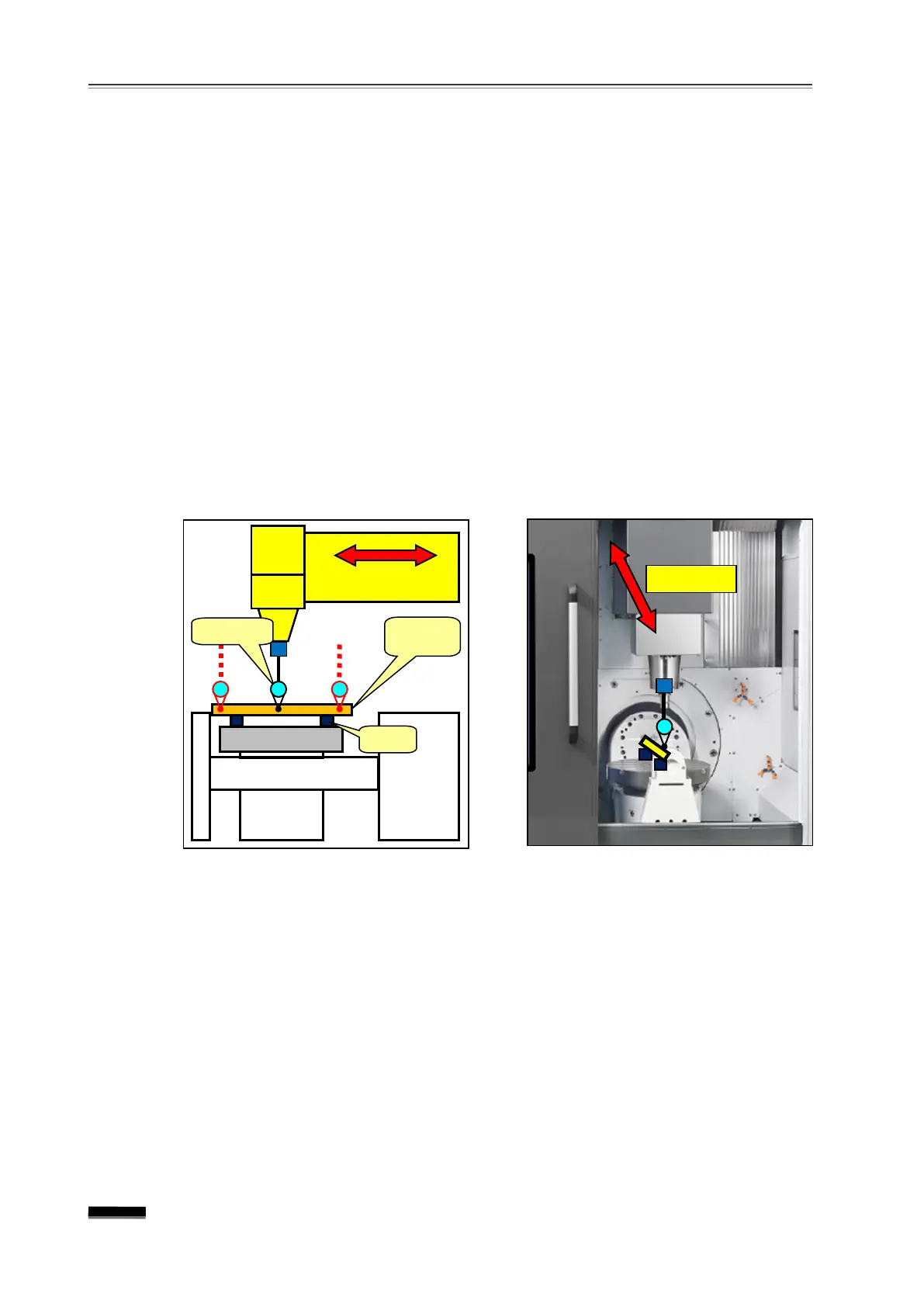

- X plane

① Measurement

Place a straight edge by laying down on the table in the Y-axis direction, set the

indicator to “0” at both ends of the straight edge by setting up an indicator on the

spindle head, and then measure the maximum difference (i.e. measurement in the

middle) while moving the Y-axis.

▪ With this method, set one end to “0” and hit the other end slightly with a driver

handle, etc. while pressing the setting area with one finger. Both ends should be

adjusted to “0 ” and the value for the center taken as a measurement value.

※ If a Straight Edge has not been prepared, measure both ends and the center on

the Y-axis plane of a square ruler instead, when measuring the X-Y squareness.

▶ Measurement position : Both ends and the center of the straight edge side.

▶Tolerance : 0.005mm / 300mm

② Adjustment

If the straightness on the Y-X plane of the Y-axis is wrong, an irregularity of the

machine feed level could be a possible cause, in which case re-leveling should be

performed by referring to “Machine Level Operation.”

▪ If the problem is not resolved by re-leveling as mentioned above, a Y-axis LM

Guide defect or an LM Guide misalignment could be another possible cause, in

which case it will be necessary to replace or re-align the LM Guide to resolve the

problem.

Loading...

Loading...