76

6. Machine Accuracy Measurement and Adjustment

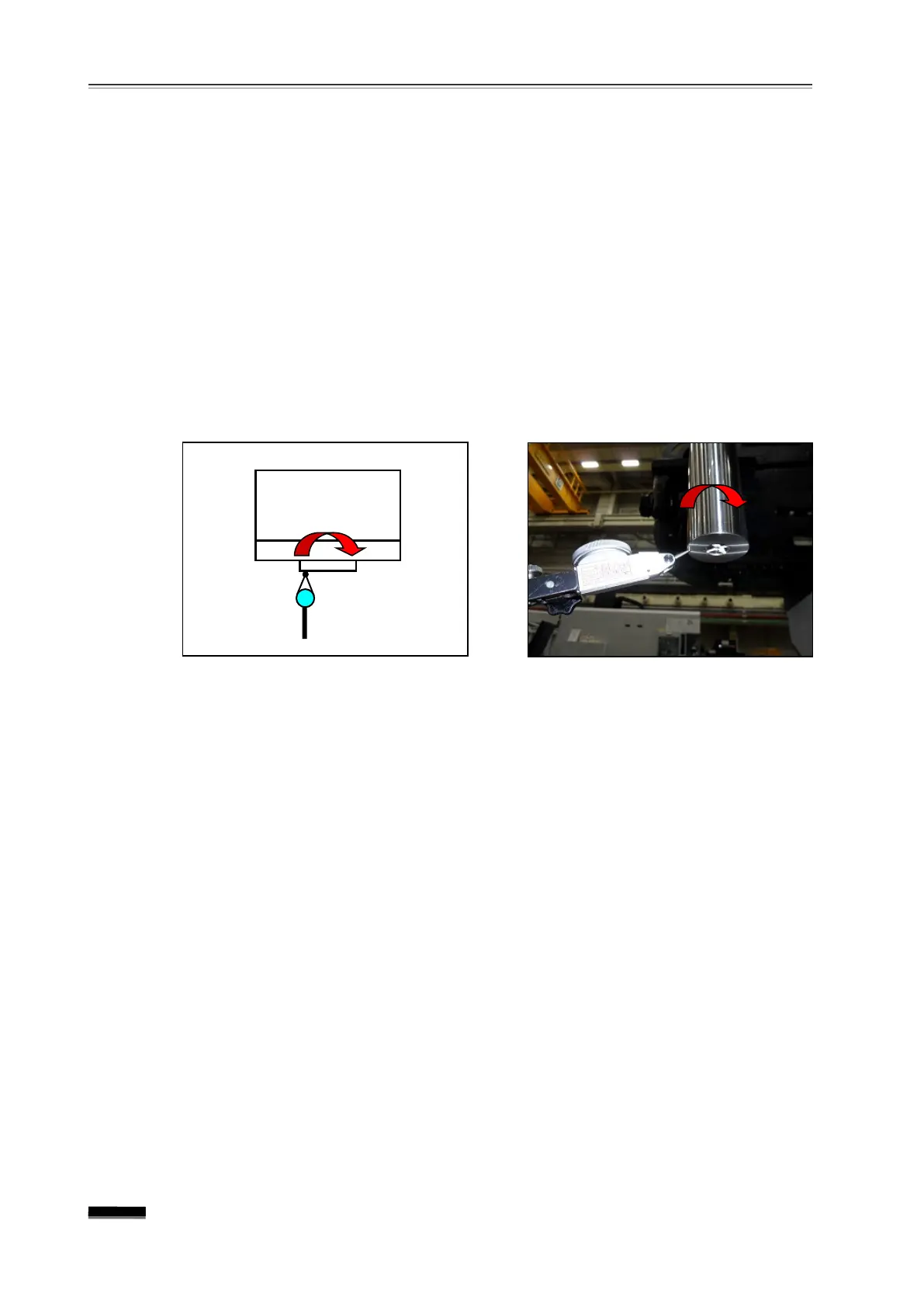

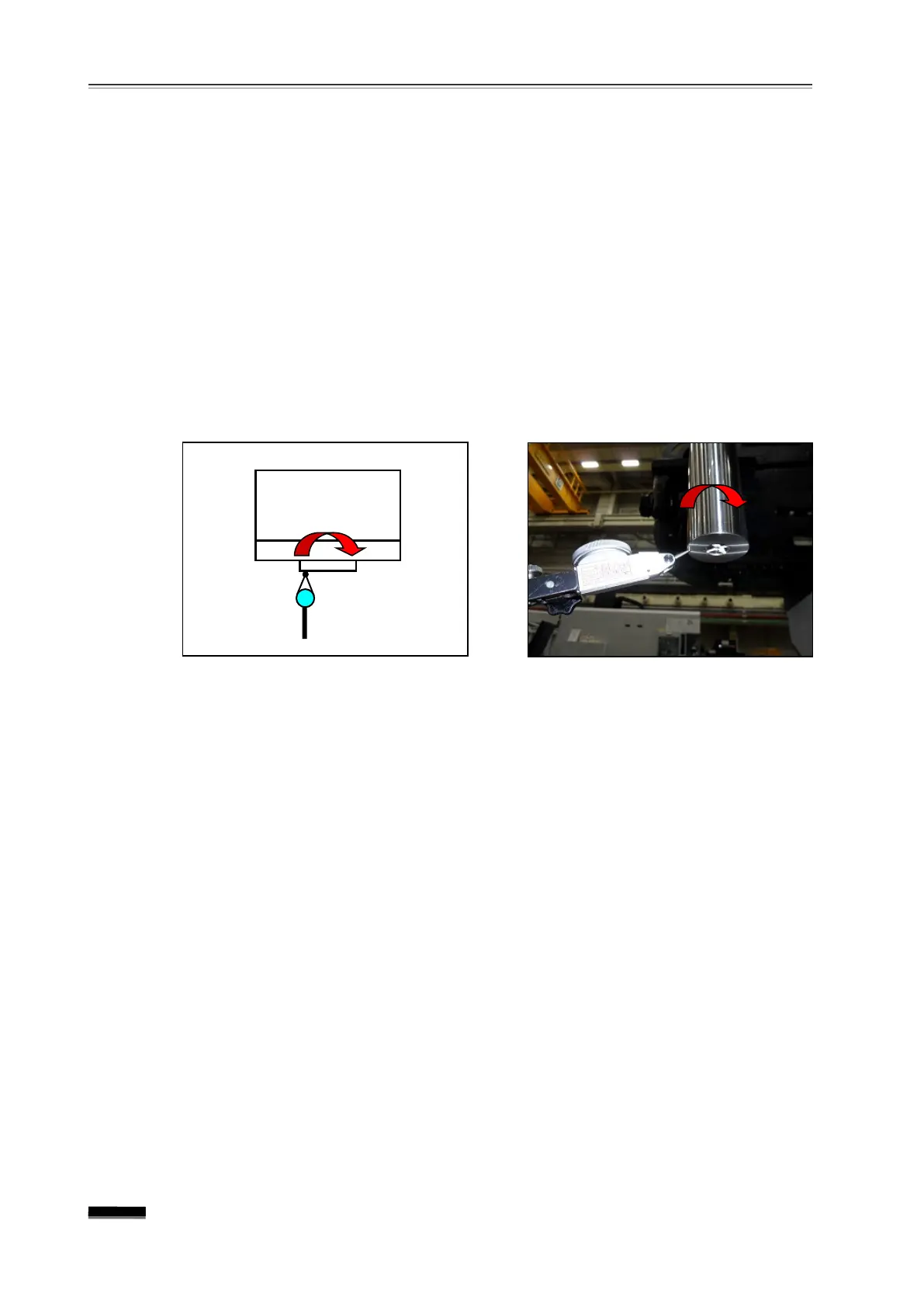

6.14 Run-Out of Spindle Cross Section

Disassemble and take out the driving key from the spindle cross section, perform “0 ”

setting while placing the indicator against the spindle, and then take the maximum run-

out value as the measurement value by rotating the spindle at low speed.

※ If the Test Bar is inserted, apply grease to the polished surface of the end cross

section of the Test Bar or its center drilling position. Attach a steel ball and measure

the Run-Out at the highest point of the ball using an indicator.

▶ Measurement position : Spindle cross section or Test Bar end cross section

▶ Tolerance : 0.005 mm

Movement of the spindle in the Z-axis direction is generally presumed to be associated

with a problem with the spindle main bearing, in which case the bearing will have to be

replaced.

Loading...

Loading...