72

6. Machine Accuracy Measurement and Adjustment

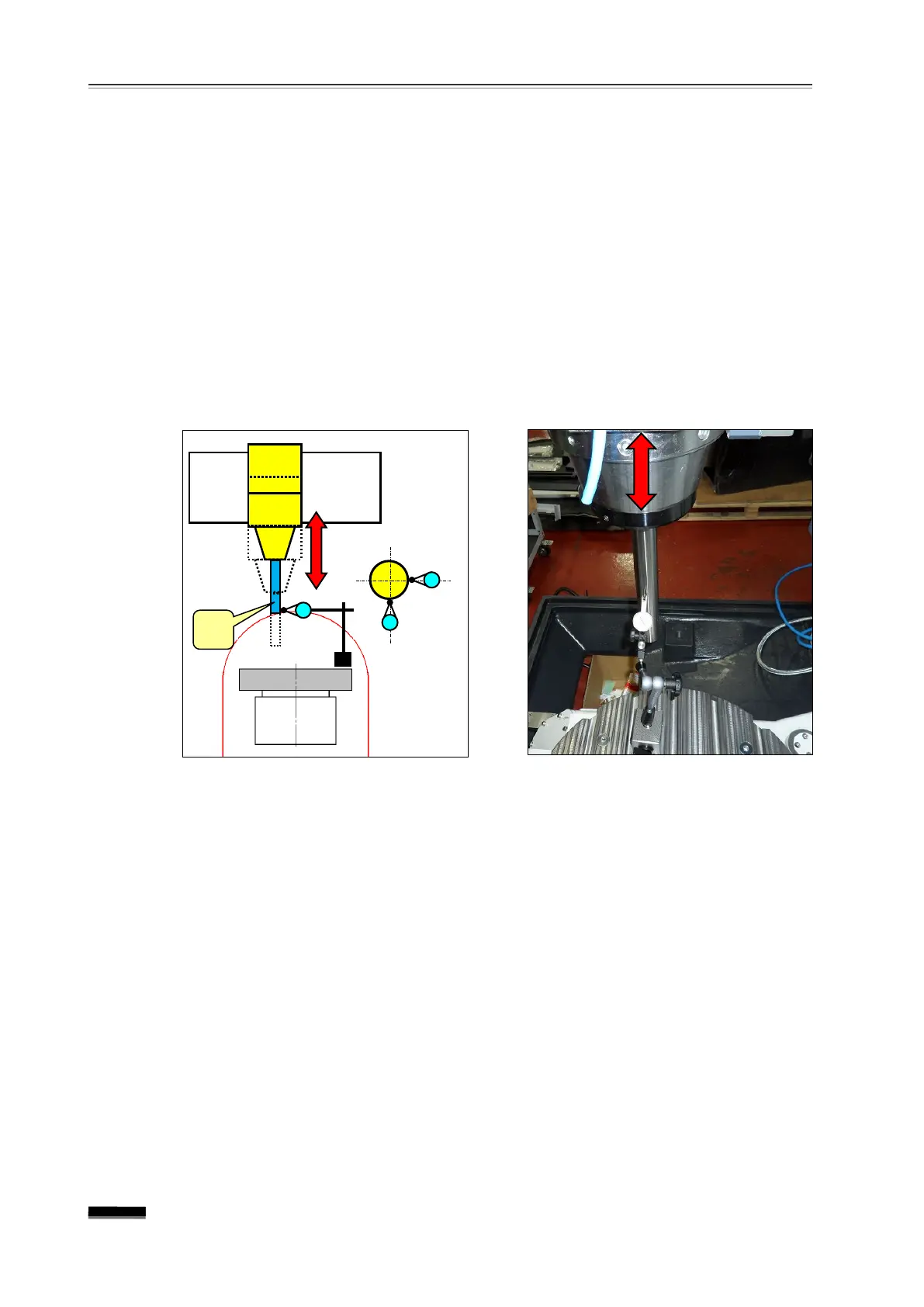

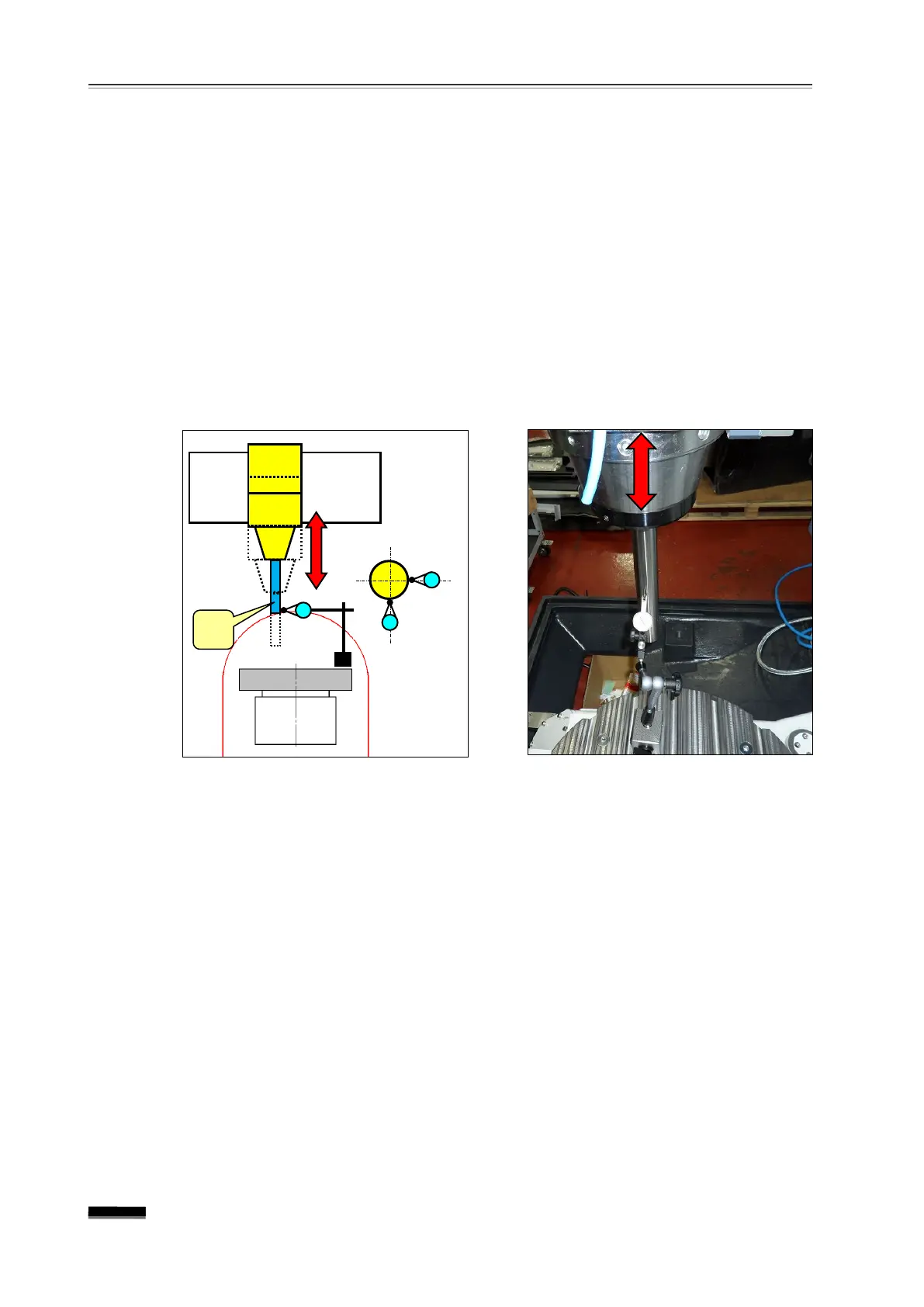

6.13 Spindle centerline and Z-axis feed parallelism

Set up a test bar on the Spindle and an indicator on the Table. Contact the gage at the

highest point at the end of the test bar. Measure the spindle run-out by rotating the

spindle by hand. Stop the spindle at the middle point between the max. and min. run-

Measure the difference between the entrance and end of the test bar by feeding the Z-

axis.

▶ Measurement position : Height of the same block position of the Y-

positions

▶ Tolerance : 0.010mm / 300mm

) Adjustment

In general, it is highly unlikely that deformations of the axial or spindle squareness will

occur in an L/M guide machine. However, in the case of squareness deformation due to

a severe collision, etc., the squareness can be corrected by adjusting the thickness of

the liner to be assembled in the spindle housing assembly area.

※ In this case, it must be corrected only after loosening the spindle housing fixing bolt

to see if it has been pushed to one side due to an unexpected impact, and since this

accuracy is related to

6.7 Spindle centerline and X-axis movement squareness

for the X-Z direction and

6.8 Spindle centerline and Y-axis movement

squareness

for the Y-Z direction, take the measurement first and review the error

amount and direction before making any adjustment

.

X-Z direction

Loading...

Loading...