78

6. Machine Accuracy Measurement and Adjustment

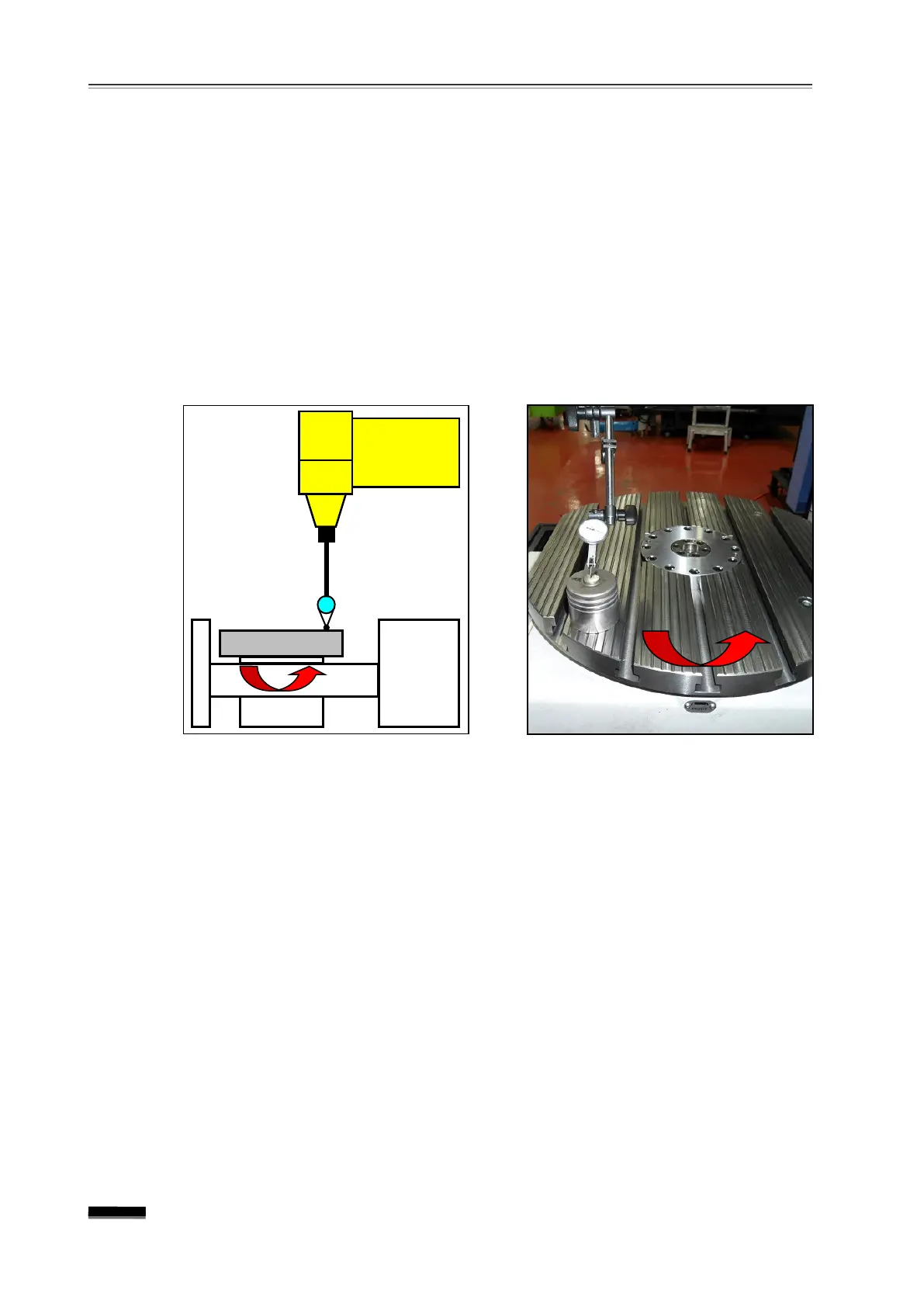

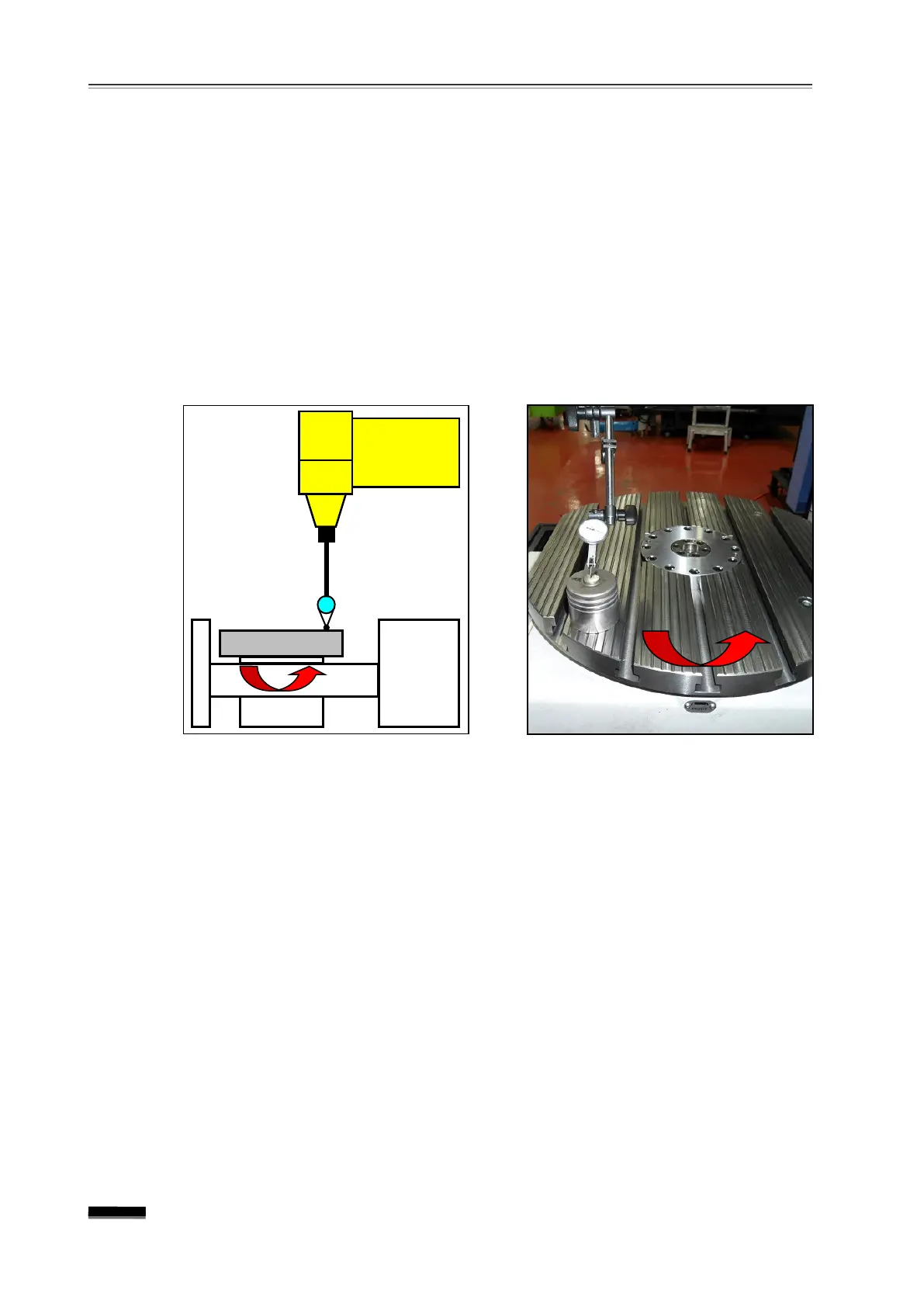

6.16 Run-Out of Table Top Surface

In the B0. condition, install an indicator on the spindle, set the indicator to “0 ” while a

gage is making contact with the table top at a point 150mm away from the center, and

take the maximum difference in height as the measured value by rotating the C-axis in

the Handle Mode.

▶ Measurement position : A point on the table top 150mm away from the table top

center

▶ Tolerance : 0.020mm / Ø300mm

Because the table top run-out is related to the C-axis bearing and table precision, it is

highly unlikely to go wrong. However, if there is a problem, adjust it as follows:

① In the event of severe collision: As C-axis bearing deformation is a possible cause,

replacement of the bearing should be considered.

② Deformation, etc. of the actual table: Re-polish the table top surface.

Loading...

Loading...