43

6. Machine Accuracy Measurement and Adjustment

6.2 Y Axis Movement Straightness

- Z plane

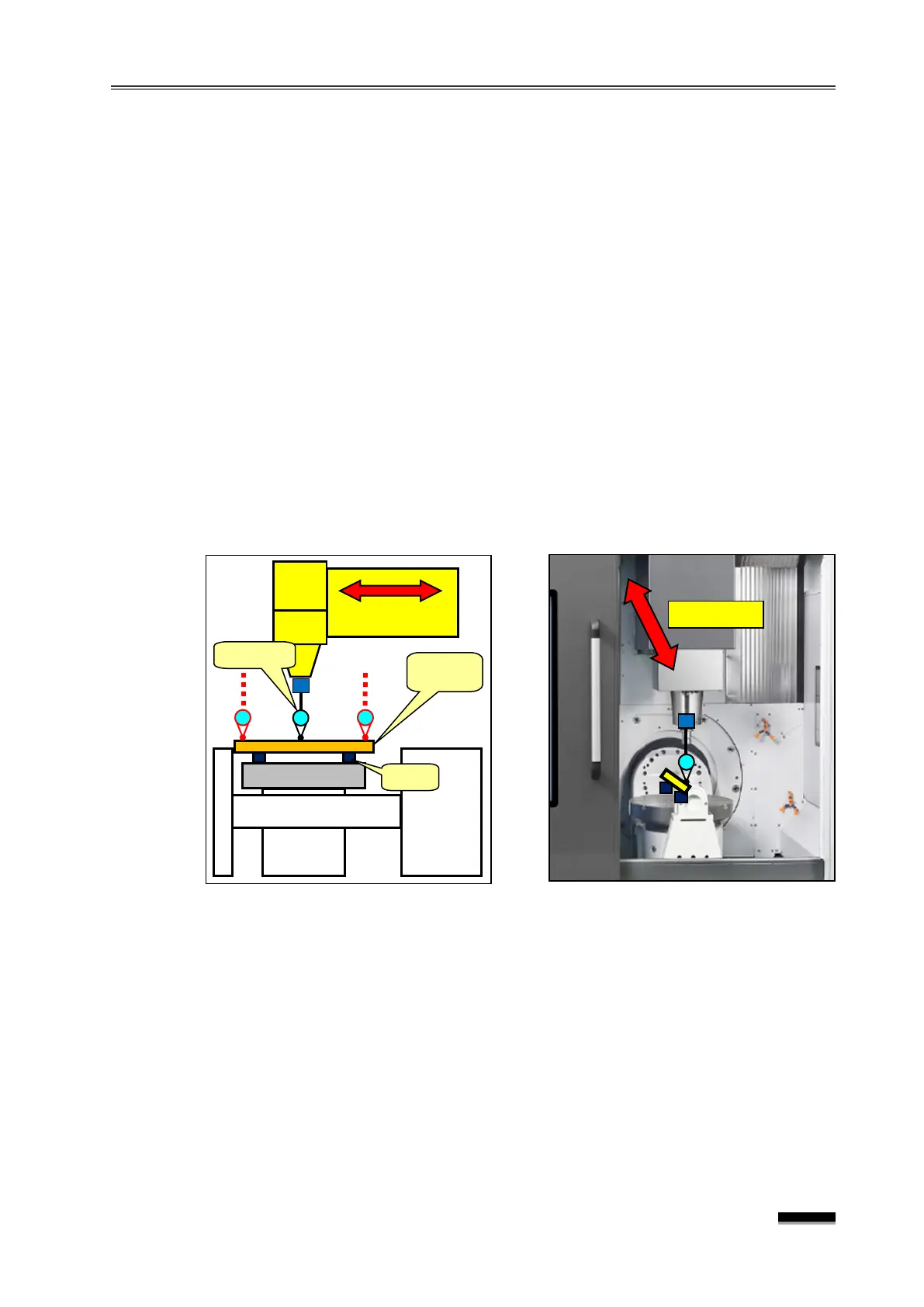

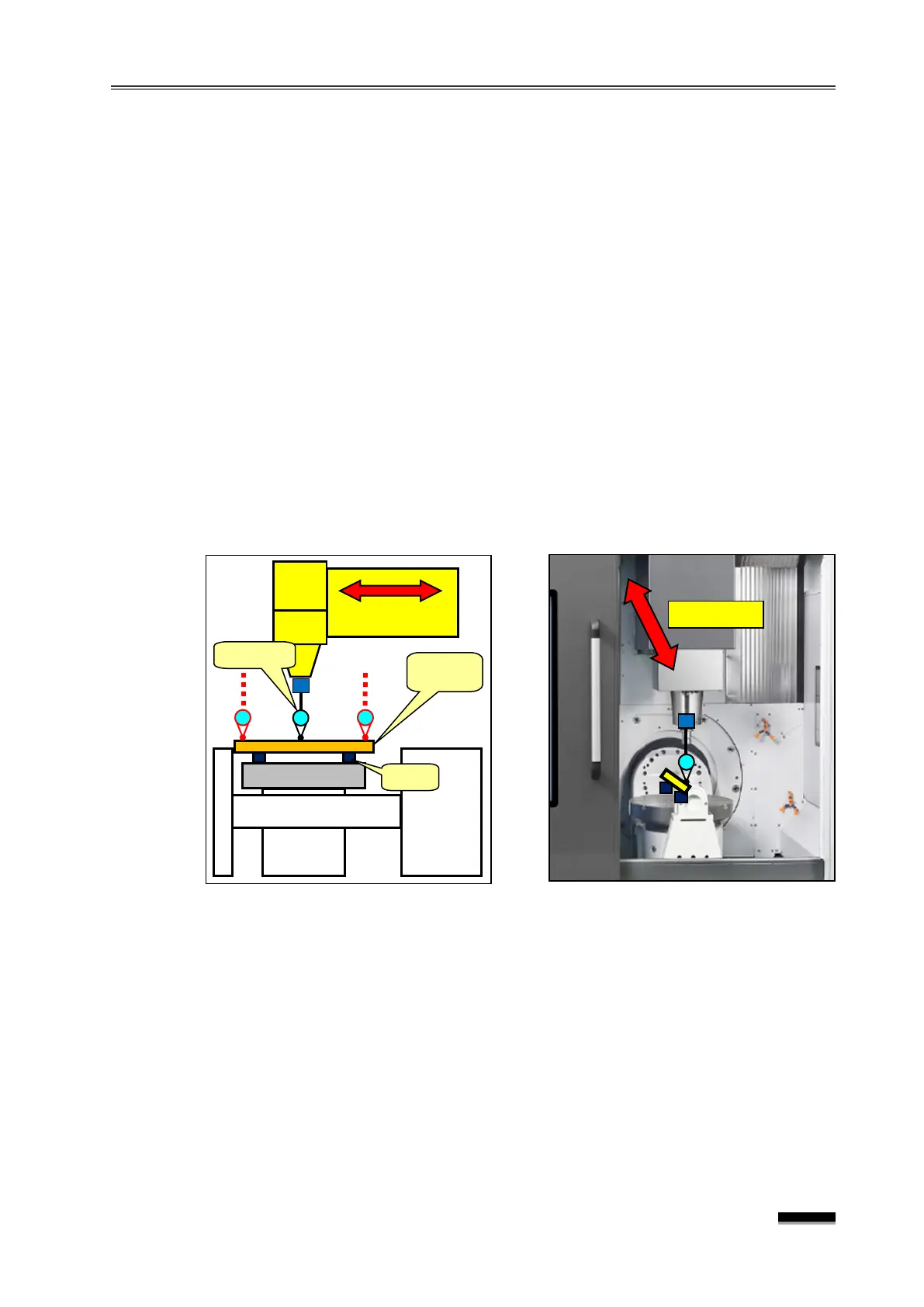

① Measurement

Place two blocks whose height is equal in the Y-axis direction on the table and place

a straight edge over it in the upright position, and then set up an indicator on the

spindle head and set it to “0 ”

at both ends of the

upper side of the straight edge, and

measure the maximum difference (i.e. the measurement in the middle) while moving

the Y-axis.

▪ If the measurement value is not “0” when measuring one end with the other

to “0,” take half the amount of the error as the measurement value.

※ If a Straight Edge has not been prepared, measure both ends and the center on

the Y-axis plane of a square ruler instead, when measuring the Y-Z squareness.

▶ Measurement position : Both ends and the center of the straight edge.

▶ Tolerance : 0.005mm / 300mm

② Adjustment

If the straightness on the Y-Z plane of Y-axis is wrong, an irregularity of the machine

feed level could be a possible cause, in which case re-leveling should be performed

by referring to “Machine Level Operation.”

▪ If the problem is not resolved by re-leveling as mentioned above, a Y-axis LM

Guide defect or an LM Guide misalignment could be another possible cause, in

which case it will be necessary to replace the LM Guide or re-align it to resolve the

problem.

Loading...

Loading...