47

6. Machine Accuracy Measurement and Adjustment

[2] Squareness

6.4 X-Z axis cross-squareness

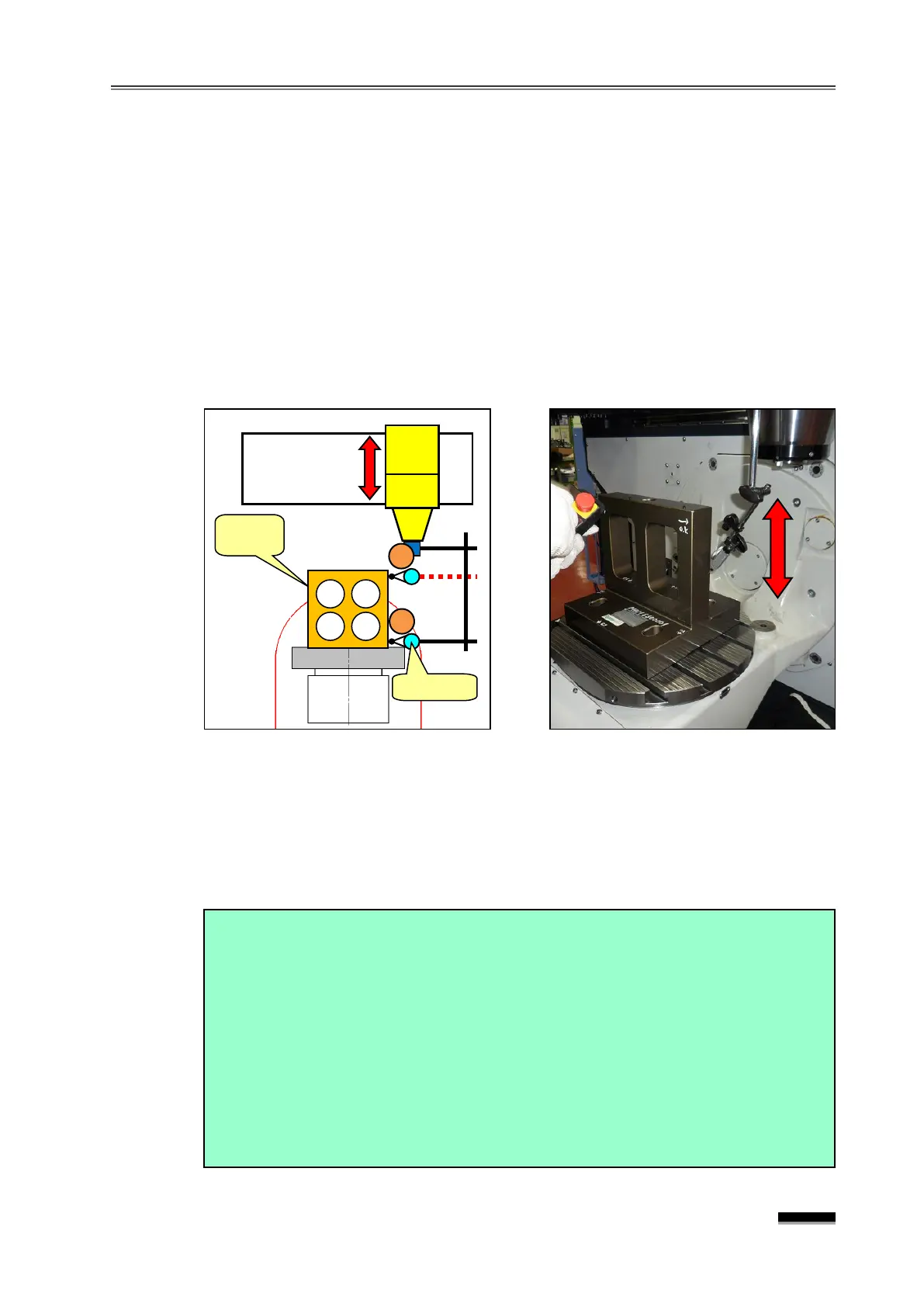

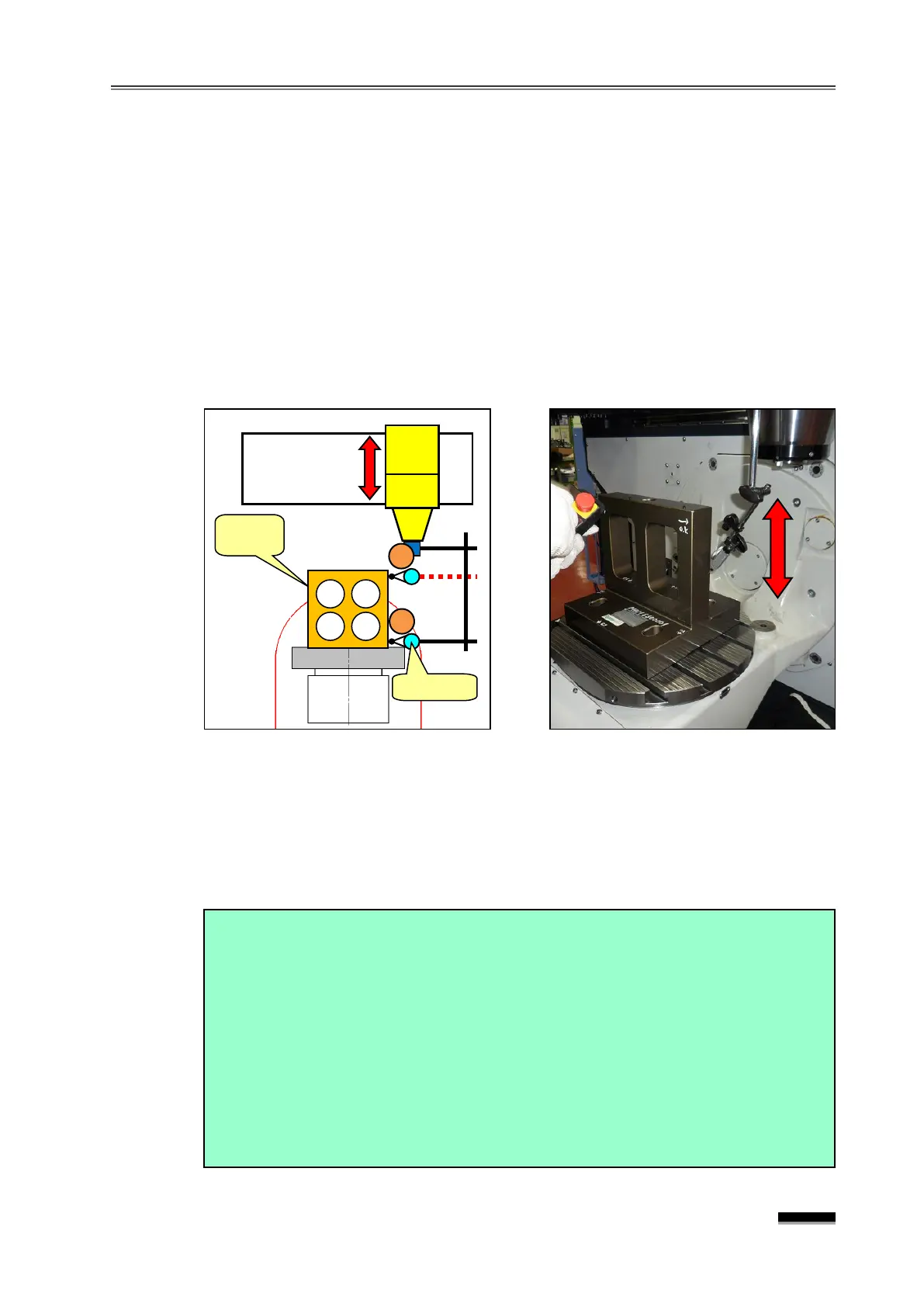

Place a square ruler in the upright position on the table in the X-axis direction at the B0.

position, set the indicator to “0 ” at the end(ⓑ

) of the

vertical plane on the square ruler by

setting up an indicator on the spindle head, and then measure the maximum difference

of the other end(

ⓐ) while moving the Z-axis.

▶ Measurement position : Lower side end and upper side end of the square ruler (ⓑ-ⓐ

▶

Tolerance : 0.015mm / 300mm

First, adjust the squareness irregularity resulting from the level by performing the

machine leveling operation, and if the result is unsatisfactory, adjust (polishing on the

spot) the thickness of the right or left two shims on the L/M Block under the column to

※ Note) L/M Guide Block shim thickness adjustment (X-Z)

(1) Refer to the “X-Z squareness”

above to measure the exact squareness.

(2) Calculate the amount of the Liner polishing by calculating the length of the

square ruler and the distance between the Y-axis L/M Guide’

s two slide blocks.

▪ Since the distance between the two L/M Blocks is 400mm, multiply the

squareness measurement by 1.3.

(3) Loosen the Y-axis L/M Guide’s Block fixing bolt.

▪ Loosen the right hand side bolt if ⓐ is “+”, and the left side bolt if it is “-.”

Loading...

Loading...