71

6. Machine Accuracy Measurement and Adjustment

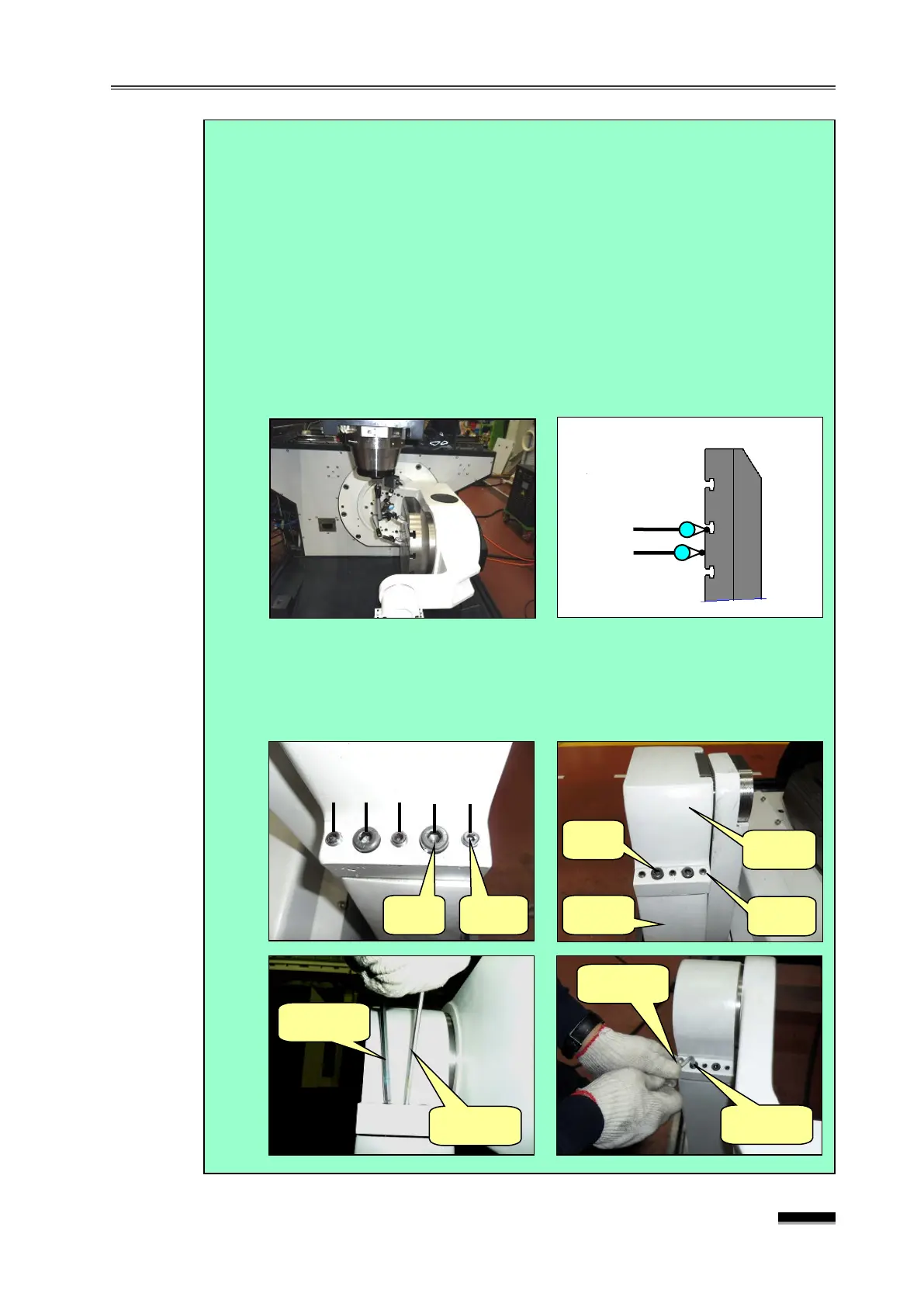

(6) Set up two indicators on the spindle head, perform “0” setting while the

needle makes contact with the T-groove side of the table end and table

top, and then secure the bearing body.

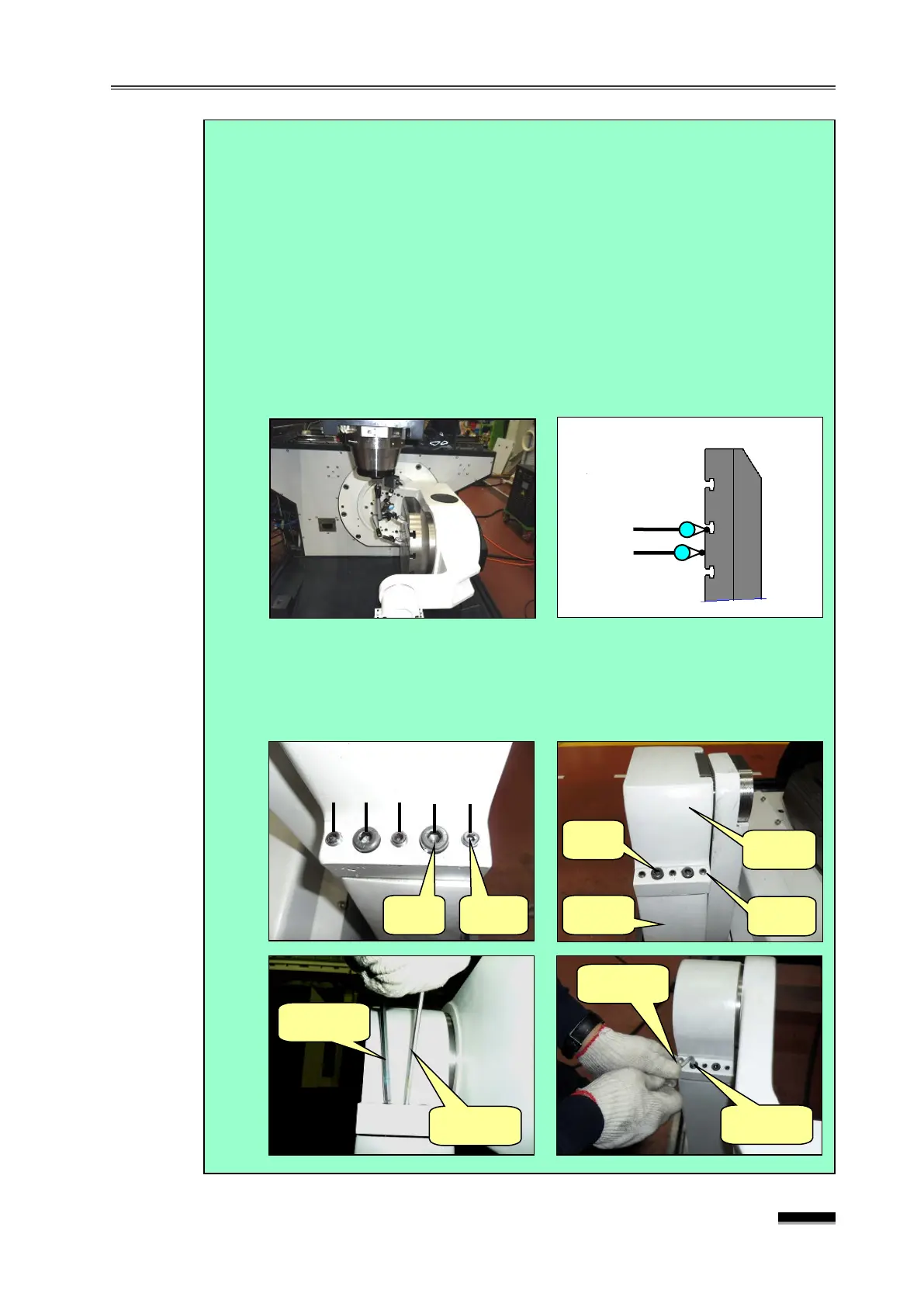

① Lock the Adjust Bolts (6ea) carefully to make contact with the 160601-

02058C Support Body.

② While checking the indicator installed on the table, tighten the Adjust

Bolt and fixing bolt alternately so that a condition is reached whereby

the 6 adjust bolts are pushed with equal force to strongly tighten the

fixing bolts, with the indicator needle remaining unchanged.

③ Again, check the B-axis in paragraph (7) to see if the value is within the

tolerance by measuring the table top and Y-axis parallelism at B0. and B90.

(7) Hold the 5mm and 6mm L-Wrenches at the same time. First, slightly

tighten them at the same time in the order of ②-③, ③-④, ①-②, ④-⑤ to

make sure that the indicator needle does not move. Then, strongly

tighten using the same method while holding the long side.

Loading...

Loading...