34

5. Machine Leveling

① Send the machine to X0. Y0. Z400. position.

② Clean the table top thoroughly and install the levels to which Absolute Level “0 ”

Setting was completed in X- and Y-axis respectively such that the table top center

comes to the middle of the level.

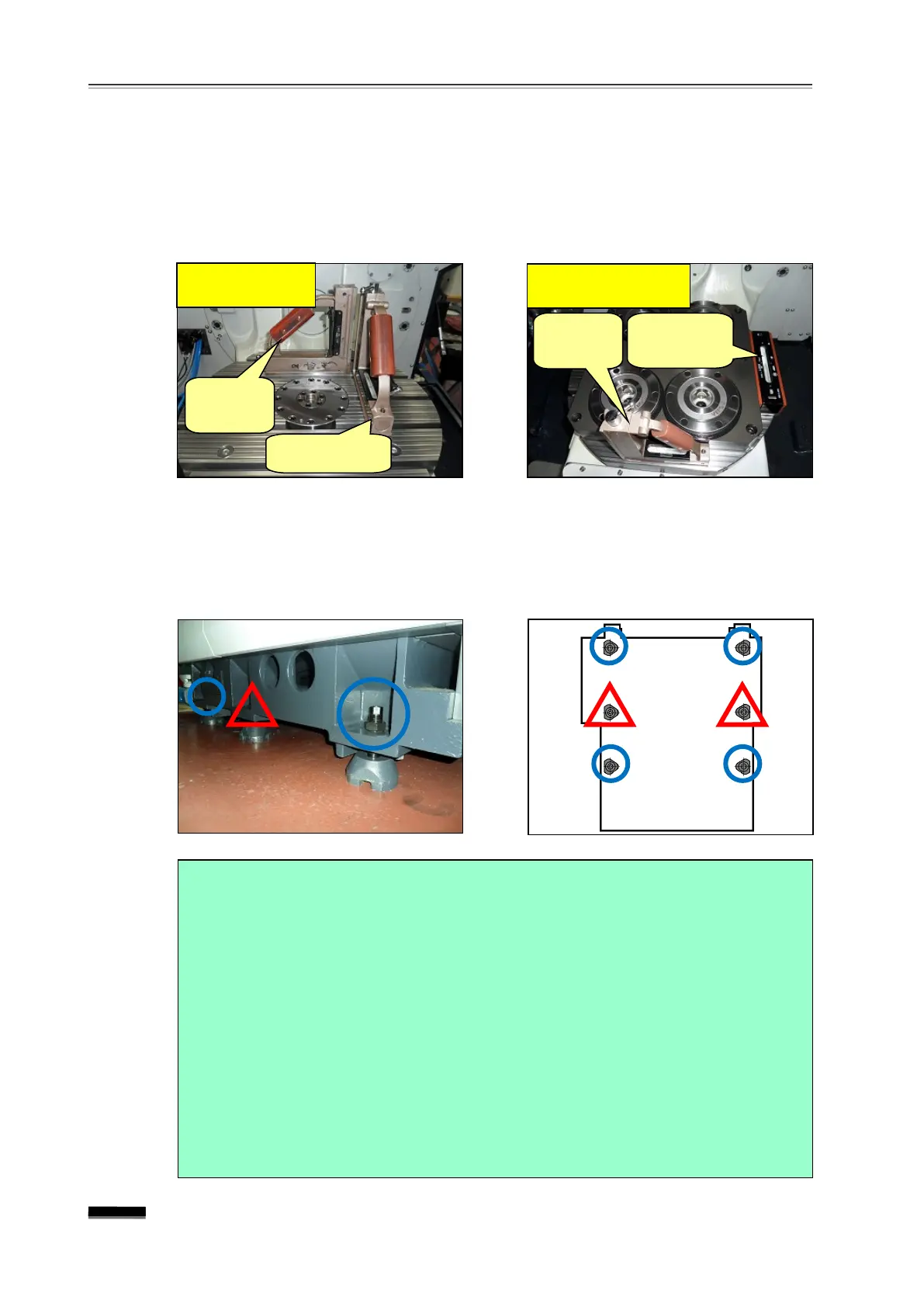

3) Absolute Level Operation

① Slightly loosen the 2 bolts in the middle from among the 6 level bolts so that a gap is

created with the level block.

②

Adjust the 4 remaining level bolts until X and Y direction level on the table becomes “0. ”

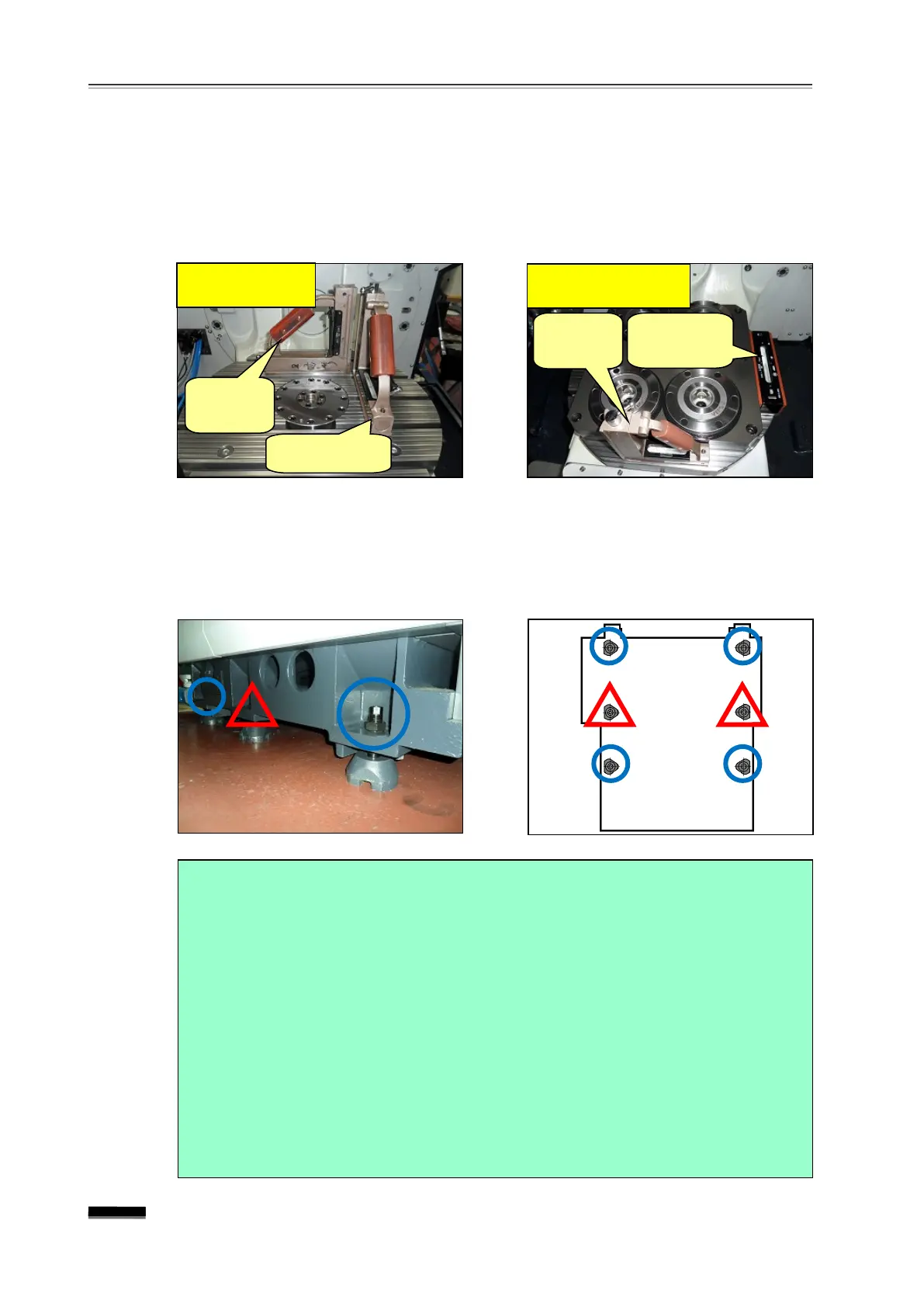

Equipment for

installing AWC

direction

direction

※ Note) Matters to be checked in advance when performing the machine

absolute leveling operation

(1) Equal torque must be applied to each level bolt.

▪

Stronger or weaker torque applied to just one level bolt may cause overall

level to go wrong later or the machine to get twisted.

(2) The leveling work must be finished in the direction in which the level bolts

are locked.

▪

When adjusting the level while raising or lowering the level bolt, the operation

must be finished while raising the level bolt at all times. Even in case where

the level is adjusted while lowering the level bolt, lower the bolt a little more

than expected and, then, finish the operation while raising the level bolt.

General standard

equipment

direction

Loading...

Loading...