66

6. Machine Accuracy Measurement and Adjustment

[3] Parallelism & Run Out

6.11 Table top and X-axis feed parallelism

Measurement

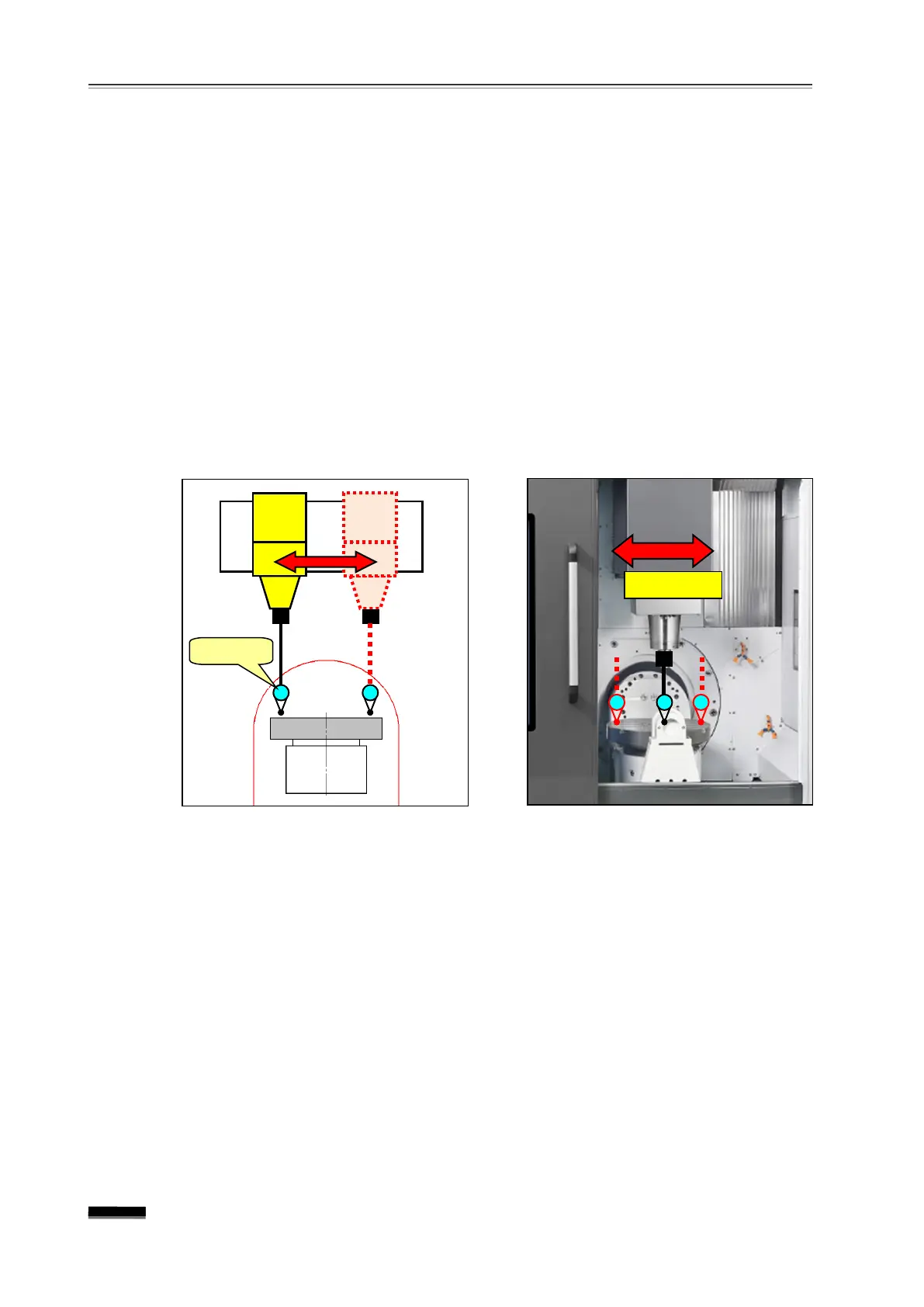

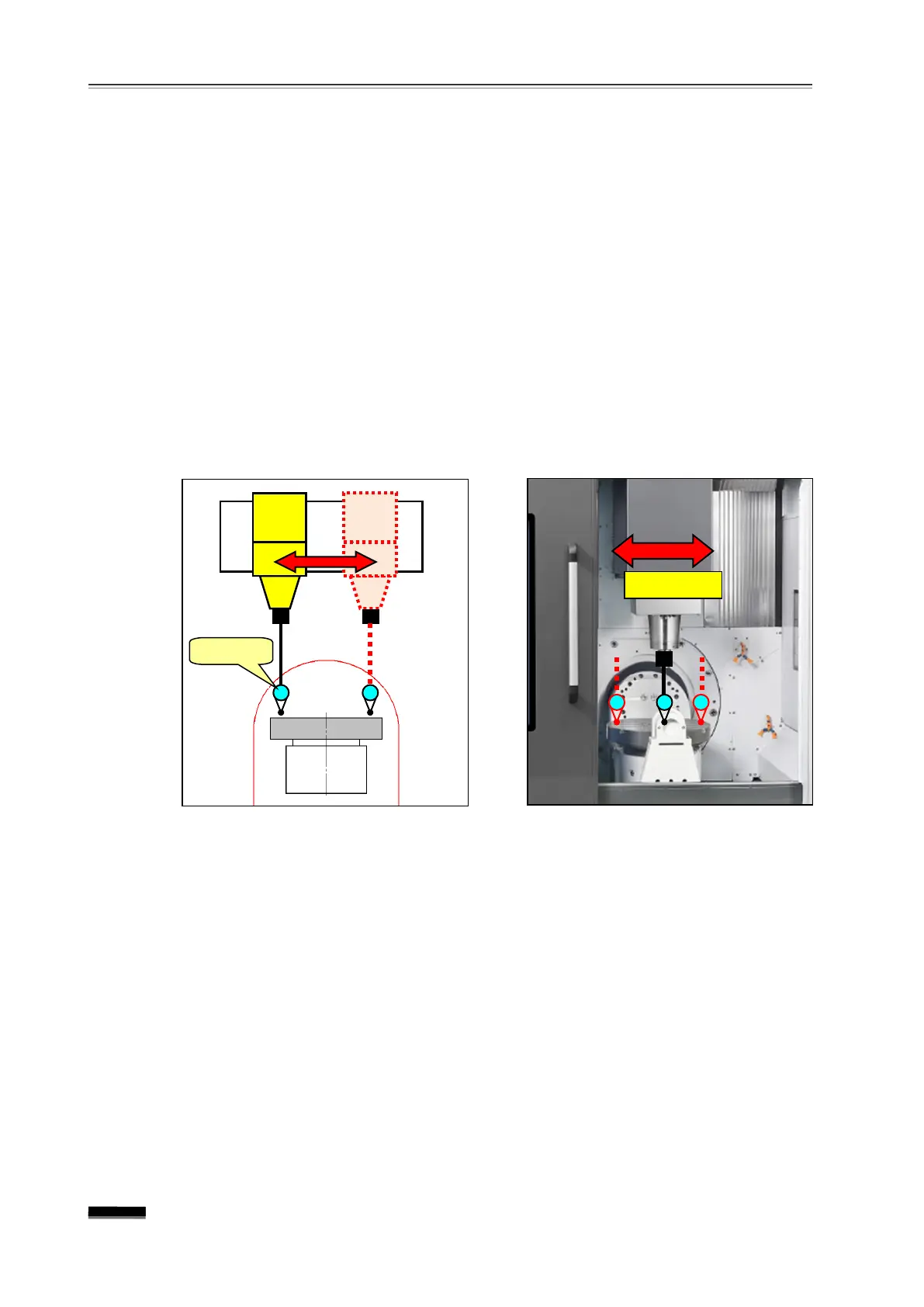

① After setting up an indicator on the spindle, transfer the X-axis to X-150.

② Perform “0” setting on the indicator set up to the spindle at a table surface about

150mm away from the table center in the Y-axis “ -” direction.

③ Move the X-axis about 300mm in the “+” direction and measure the error amount

shown on the indicator.

▶

Measurement position : Height of the same table top position of X-

position

▶ Tolerance : 0.010mm / 300mm

) Adjustment

Adjust the table top and X-axis feed parallelism by setting the B-axis machine reference

Loading...

Loading...