FUEL SYSTEM

34

CS-2511WES

251Ws

4-9 Testingcarburetor

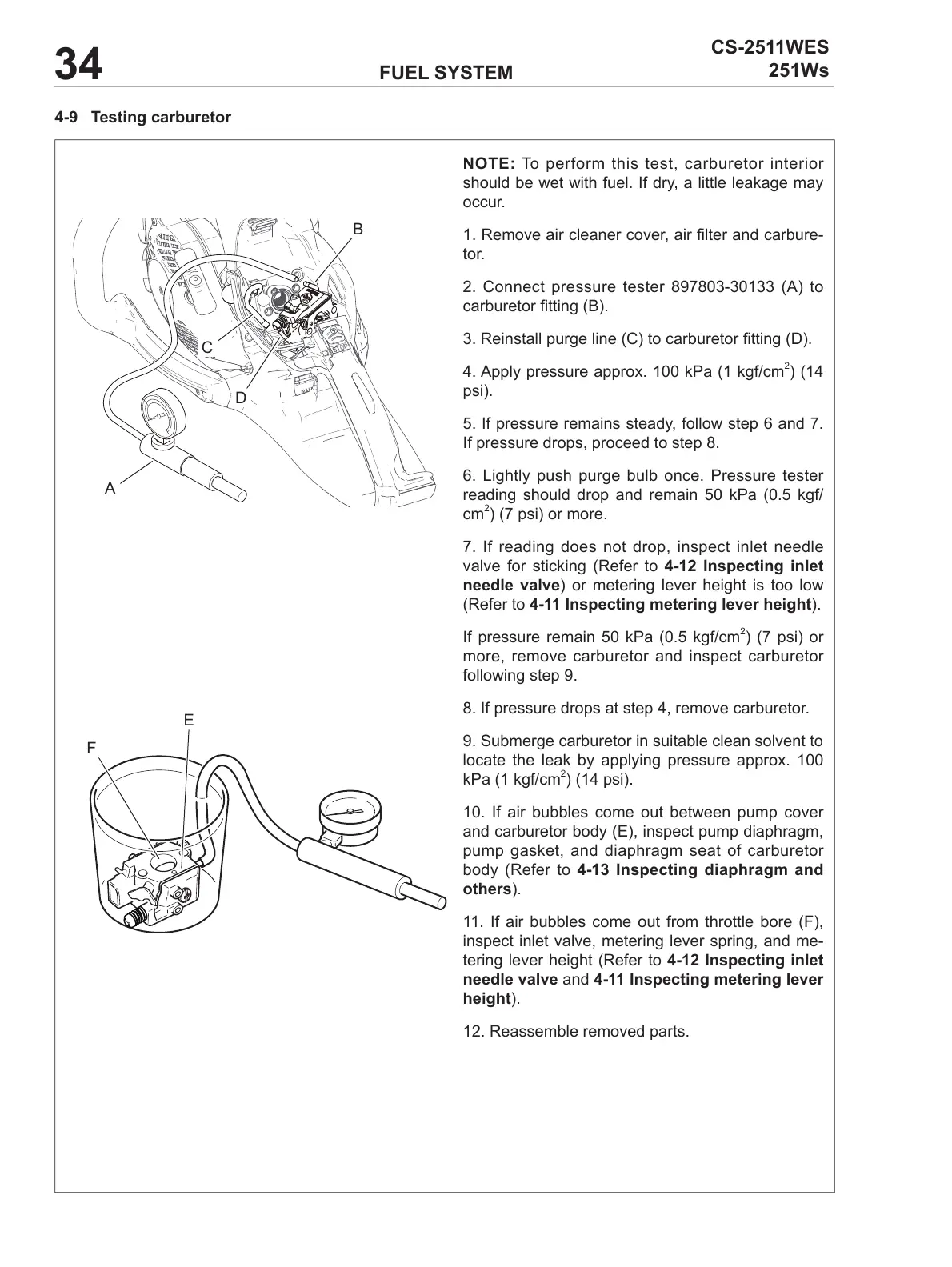

NOTE: To perform this test, carburetor interior

should be wet with fuel. If dry, a little leakage may

occur.

1. Remove air cleaner cover, air lter and carbure-

tor.

2. Connect pressure tester 897803-30133 (A) to

carburetor tting (B).

3. Reinstall purge line (C) to carburetor tting (D).

4. Apply pressure approx. 100 kPa (1 kgf/cm

2

) (14

psi).

5. If pressure remains steady, follow step 6 and 7.

If pressure drops, proceed to step 8.

6. Lightly push purge bulb once. Pressure tester

reading should drop and remain 50 kPa (0.5 kgf/

cm

2

) (7 psi) or more.

7. If reading does not drop, inspect inlet needle

valve for sticking (Refer to 4-12 Inspecting inlet

needle valve) or metering lever height is too low

(Refer to 4-11Inspectingmeteringleverheight).

If pressure remain 50 kPa (0.5 kgf/cm

2

) (7 psi) or

more, remove carburetor and inspect carburetor

following step 9.

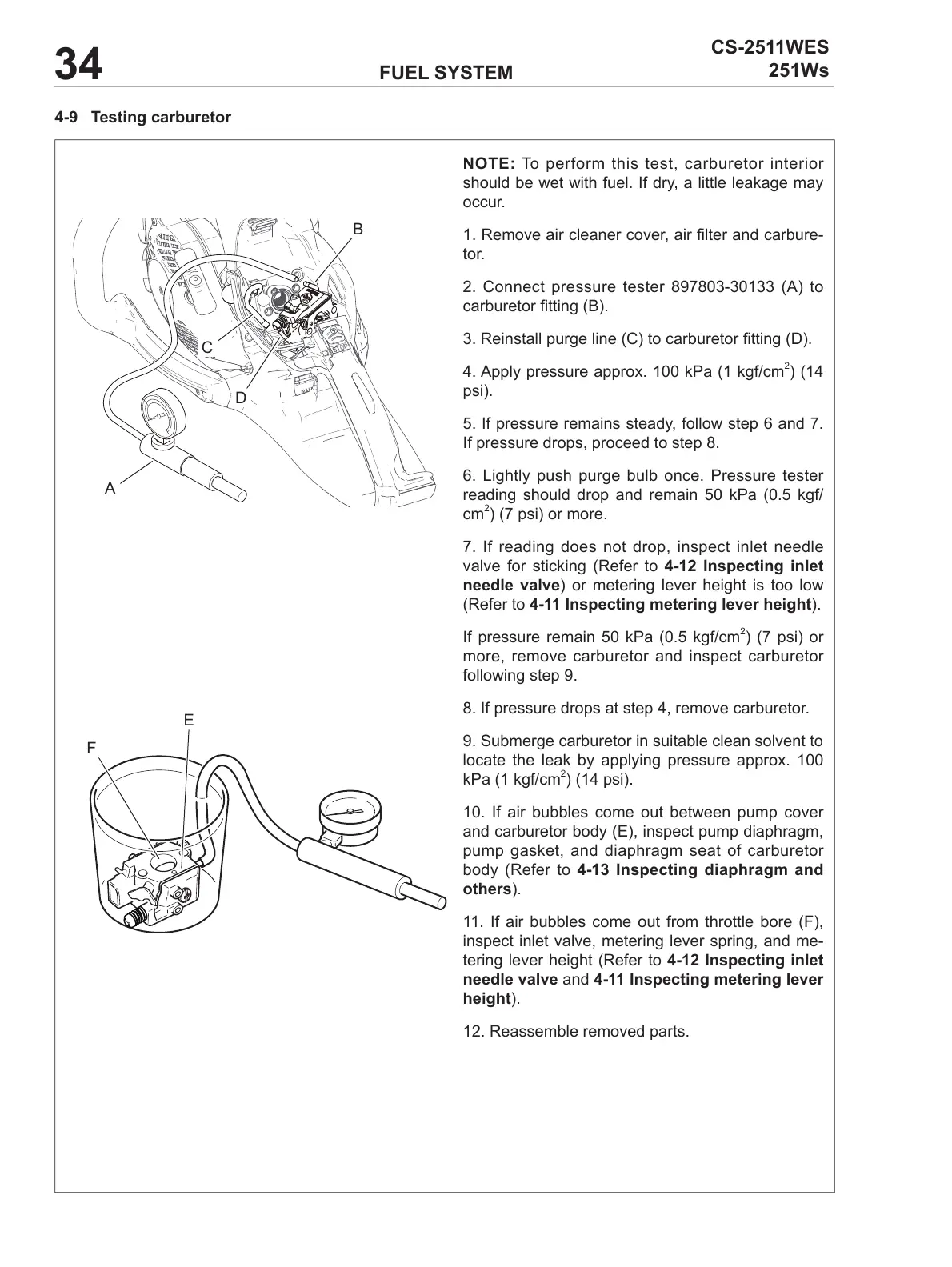

8. If pressure drops at step 4, remove carburetor.

9. Submerge carburetor in suitable clean solvent to

locate the leak by applying pressure approx. 100

kPa (1 kgf/cm

2

) (14 psi).

10. If air bubbles come out between pump cover

and carburetor body (E), inspect pump diaphragm,

pump gasket, and diaphragm seat of carburetor

body (Refer to 4-13 Inspecting diaphragmand

others).

11. If air bubbles come out from throttle bore (F),

inspect inlet valve, metering lever spring, and me-

tering lever height (Refer to 4-12 Inspecting inlet

needle valve and4-11Inspectingmeteringlever

height).

12. Reassemble removed parts.

E

F

A

D

B

C

Loading...

Loading...