Analog Sensor Control Software Overview • 5-3

5.2 Analog Sensor Control

The Analog Sensor Control reads the values from one

or more analog sensors, compares them to a set of Cut In/

Cut Out setpoints, and operates a digital output (such as a

relay) based on the analog input in relation to the

setpoints.

An Analog Sensor Control module performs three

functions:

• COMBINER - Up to four analog inputs are

combined into a single analog value.

• CUT IN/CUT OUT CONTROL - The combined

input value is compared to a Cut In/Cut Out

setpoint. Based on this comparison, a digital output

will be turned ON or OFF.

• ALARMING - Alarms and notices can be

generated based on the combined value of the

inputs and its relation to a set of high and low alarm

and notice setpoints.

5.2.1 Control Strategy

The application combines multiple analog inputs into a

single output, using either the primary combination

method or the alternate combination mode, depending on

the state of the Use Alternate Combination property.

The primary and alternate combination methods may

be configured to be one of the following:

• Average - of all defined inputs

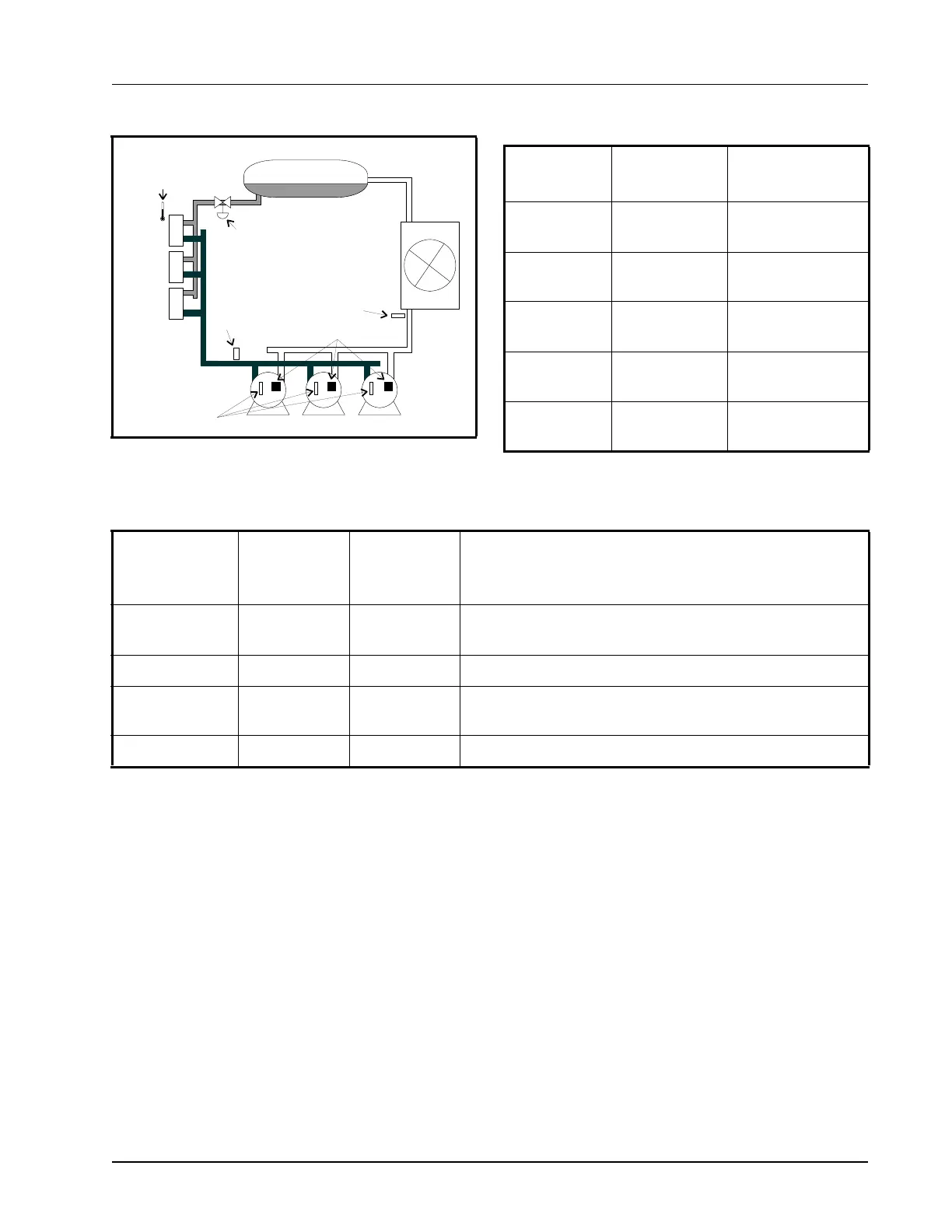

Figure 5-1 - Diagram of a Suction Group

DISCHARGE

PRESSURE

LIQUID RECEIVER

CASE CIRCUIT

OIL

PRESSURE

CIRCUIT

CASE TEMP

(FOR FLOATING)

LIQUID LINE

SOLENOID

26507005

DDD

OIL RESET SWITCHES

Input Sensor Type

Wiring

Instructions

Suction

Pressure

100 lb. Eclipse

transducer

(see Table 9-1 on

page 9-3)

Discharge

Pressure

500 lb. Eclipse

transducer

(see Table 9-1 on

page 9-3)

Oil Pressure

200 lb. Eclipse

transducer

(see Table 9-1 on

page 9-3)

Case Circuit

Temperature

Temperature

(see Table 9-1 on

page 9-3)

Oil Reset

Switches

Digital

(see Table 9-1 on

page 9-3)

Table 5-1 - Suction Group Inputs

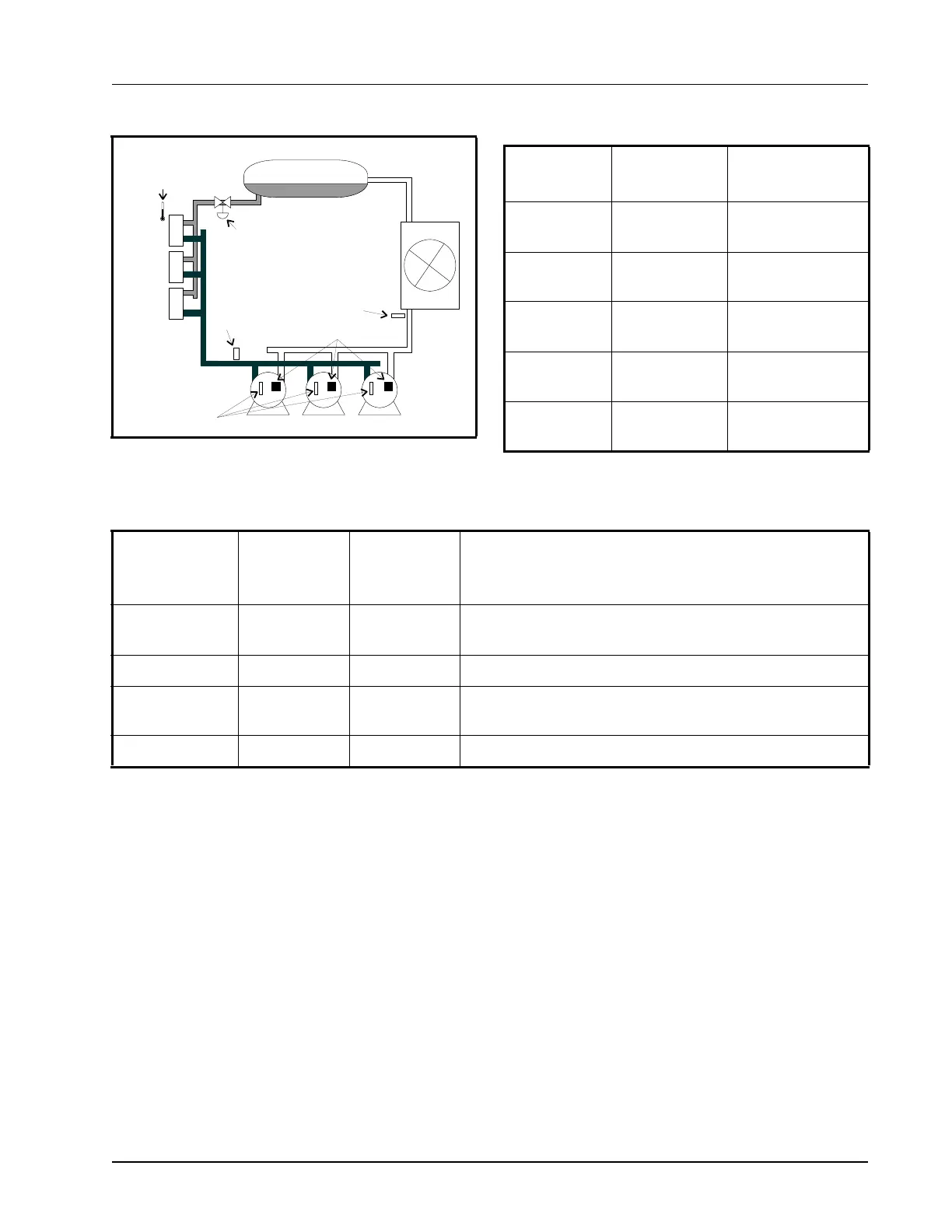

Output Device

Wire Output

Board

Contacts to:

Set Failsafe

Dip Switch

to:

Notes

Compressor N.C. N.C. (up)

If you want a compressor to be OFF during network/power

loss, use N.O. fail-safes instead.

Unloader N.C. N.O. (down) These fail-safe settings are specifically for unloaders.

Liquid Line

Solenoid (LLS)

N.C. N.C. (up) Keeps solenoid energized during network/power loss.

Electric Defrost N.O. N.O. (down) Keeps contacts de-energized during network/power loss.

Table 5-2 - Suction Group Outputs

Loading...

Loading...