Establishing the connection

Remote control requires the installation of the

PROFIBUS-PA server. The PC must also be

equipped with a PROFIBUS-PA

card:

• The connection to Commuwin II is set up

via the PROFIBUS-PA server.

• All the devices appear in the device list

connected to the segments selected

• The settings are made in the Instrument

data menu.

• PROFIBUS-PA parameters can also be

displayed or set using the graphical

user interface.

10.6 System integration via PLC

The Mycom CLM 152 measuring transmitter

supplies measured values (OUT) cyclically

using the PROFIBUS-PA protocol. Other

PROFIBUS-PA parameters are provided using

the acyclical service.

Two modules are provided for data exchange

with the PLC and they transfer together:

• Module 1: main measured value

• Module 2: temperature measured value

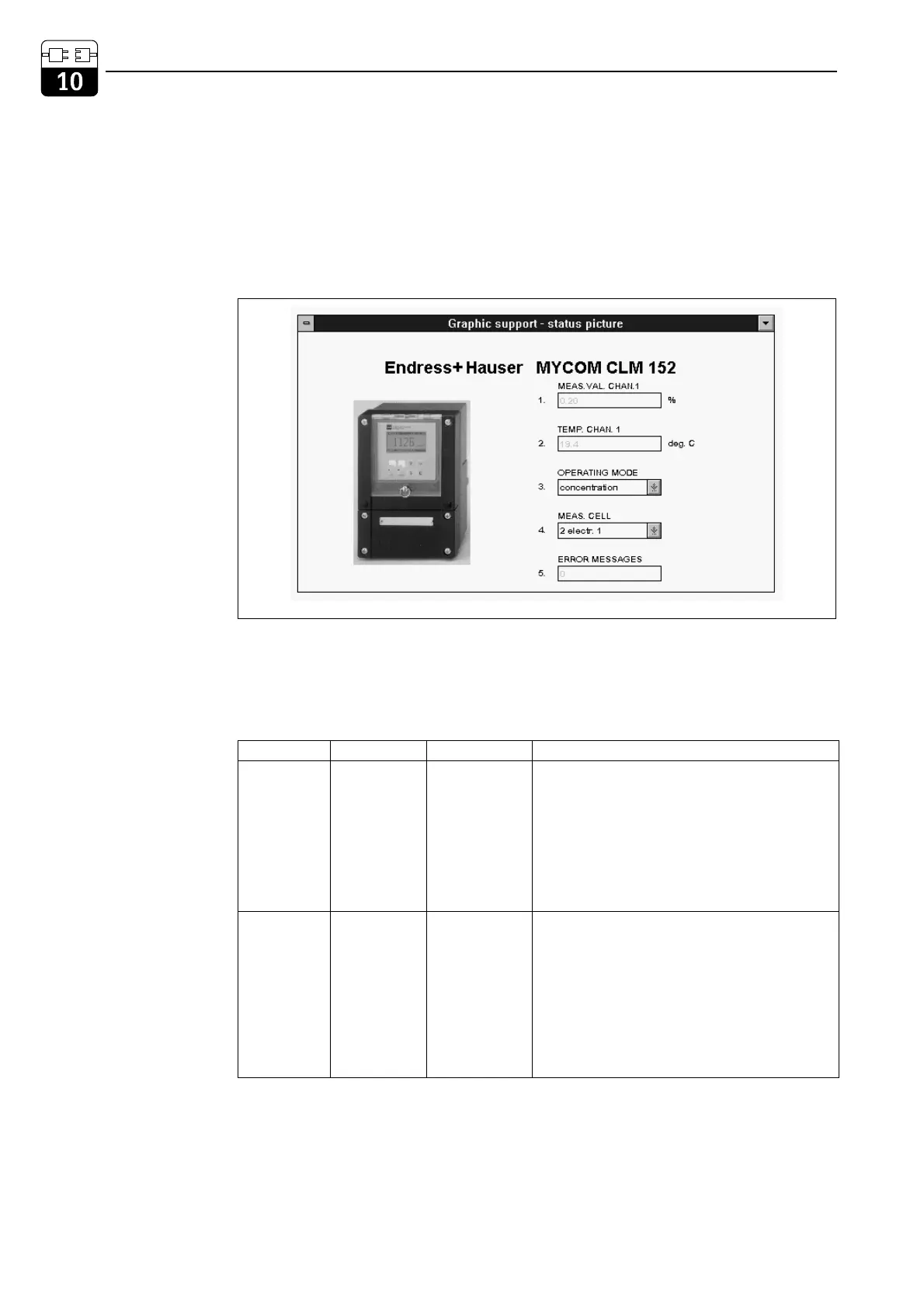

SC-IDE2.CDR

Fig. 10.4

Graphical user interface

of Commuwin II

Command Type Function

Module 1 OUT Read Current measured value of process variable in

mS/cm, kΩ cm or % and related status

- Status = 80

Hex

, Instrument OK

- Status = 0C

Hex,

Warning or alarm present.

Information is transferred byte by byte in 5

bytes which contain the

status information.

Module 2 OUT Read Current measured value of process variable in

°C

and related status

- Status = 80

Hex

, Instrument OK

- Status = 0C

Hex,

Warning or alarm present.

Information is transferred byte by byte in 5

bytes which contain the

status information.

PROFIBUS

®

interface Mycom CLM 152

66 Endress+Hauser

Loading...

Loading...